Multifunctional nano emulsion drag reducer used for shale gas fracking

A nano-emulsion, multi-functional technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of complex operation, heavy workload, high cost, reduce construction costs, improve utilization, and reduce friction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

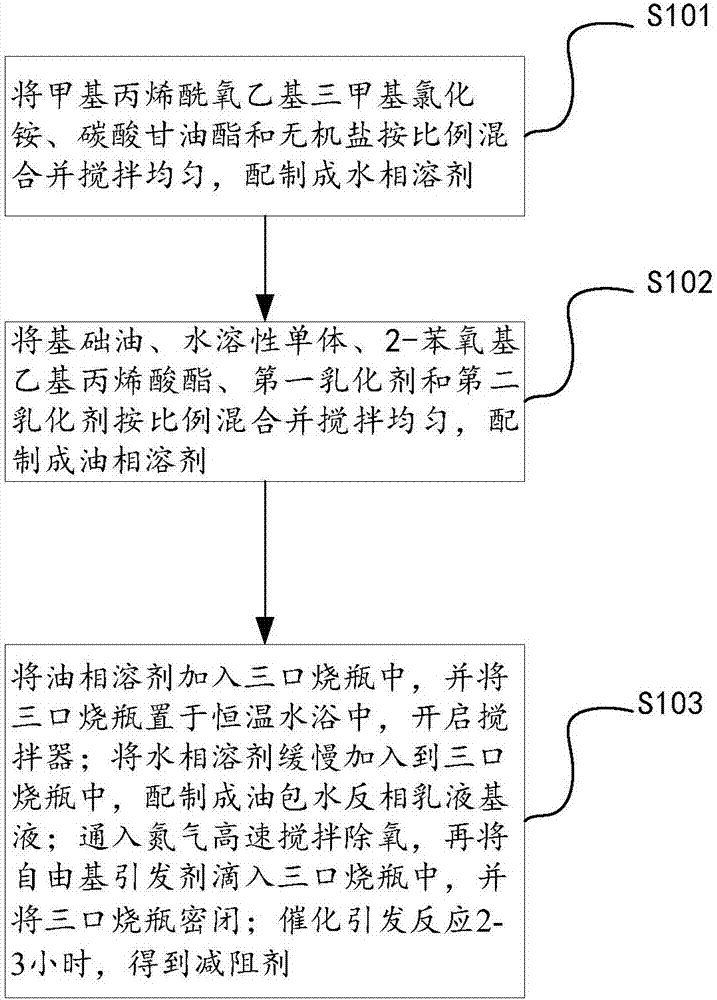

Method used

Image

Examples

Embodiment 1

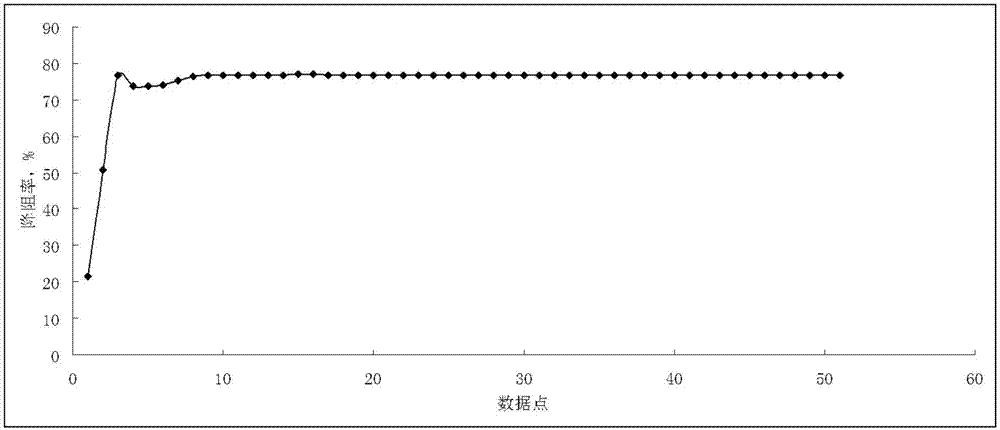

[0022] Weighing: 24g methacryloyloxyethyltrimethylammonium chloride, 40g glycerol carbonate, 2g potassium hydroxide, 80g coconut oil, 20g acrylic acid, 10g 2-phenoxyethyl acrylate, 4g Tween 80 , OP-10 2g, water 18g. Dissolve methacryloyloxyethyltrimethylammonium chloride, glycerol carbonate, and potassium hydroxide in water, mix well, and stir continuously to prepare a water phase solvent; coconut oil, acrylic acid, 2-phenoxyethyl Acrylic ester, Tween 80 and OP-10 are mixed evenly and stirred continuously to make an oil phase solvent. Add the oil phase solvent into a 250mL three-necked flask, place the three-necked flask in a constant temperature water bath at 30°C, and keep stirring; slowly drop the water phase solvent into the oil phase solvent to make it fully emulsified, and prepare a water-in-oil reaction solution phase emulsion base liquid; pass nitrogen gas into the reverse phase emulsion base liquid and stir at high speed to remove oxygen, after stirring for 20 minute...

Embodiment 2

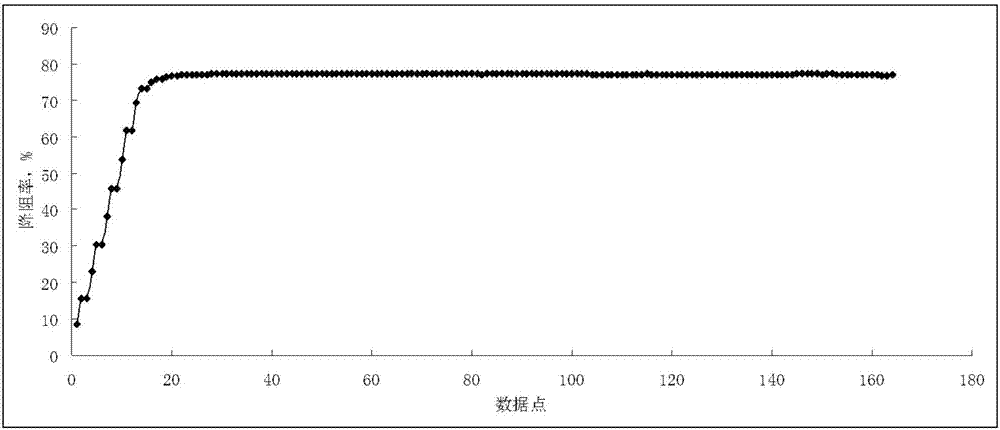

[0024] Weighing: 20g of methacryloyloxyethyltrimethylammonium chloride, 44g of glycerol carbonate, 4g of sodium chloride, 60g of white oil, 30g of dimethyldiallylammonium chloride, 2-phenoxyethyl ammonium Acrylate 6g, Tween 20 2g, OP-4 4g, water 30g. Dissolve methacryloyloxyethyltrimethylammonium chloride, glycerol carbonate, and sodium chloride in water and mix evenly, and stir continuously to prepare a water phase solvent; white oil, dimethyl diallyl chloride Ammonium, 2-phenoxyethyl acrylate, Tween 20, and OP-4 were mixed evenly and continuously stirred to prepare an oil phase solvent. Add the oil phase solvent into a 250mL three-necked flask, place the three-necked flask in a constant temperature water bath at 20°C, and keep stirring; slowly drop the water phase solvent into the oil phase solvent to fully emulsify it, and prepare a water-in-oil reaction solution. phase emulsion base liquid; pass nitrogen into the reverse phase emulsion base liquid and stir at high speed t...

Embodiment 3

[0026] Weighing: 30g of methacryloxyethyltrimethylammonium chloride, 50g of glycerol carbonate, 6g of ammonium chloride, 60g of kerosene, 20g of acrylamide, 8g of 2-phenoxyethyl acrylate, 2g of Tween 40 , OP-15 3g, water 21g. Dissolve methacryloyloxyethyltrimethylammonium chloride, glycerol carbonate, and ammonium chloride in water and mix them uniformly to make a water phase solvent; mix kerosene, acrylamide, 2-phenoxyethyl Acrylic ester, Tween 40 and OP-15 are mixed evenly and stirred continuously to make an oil phase solvent. Add the oil phase solvent into a 250mL three-necked flask, place the three-necked flask in a constant temperature water bath at 40°C, and keep stirring; slowly drop the water phase solvent into the oil phase solvent to make it fully emulsified, and prepare a water-in-oil reaction solution phase emulsion base liquid; pass nitrogen into the reverse phase emulsion base liquid and stir at high speed to remove oxygen. After stirring for 40 minutes, drop 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| resistance reduction rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com