Preparation method of greaseproof paper with rust prevention and water prevention

A technology of oil-proof paper and ammonia water, applied in papermaking, packaging paper, paper coating, etc., can solve the problems of poor waterproof and oil-proof, low surface gloss and flatness, etc., and achieve good anti-rust effect, good waterproof and oil-proof effect, The effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

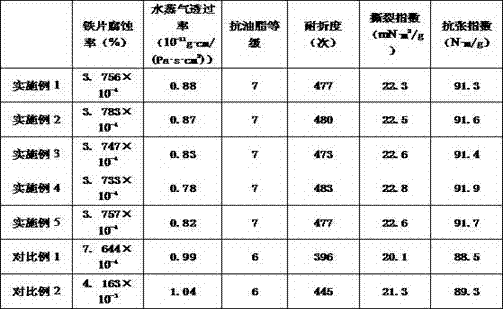

Examples

Embodiment 1

[0016] A preparation method for antirust, waterproof and oilproof paper, comprising the following steps:

[0017] (1) Mix 2g of stearic acid, 1ml of ammonia water and 50ml of distilled water, heat to 65°C and stir for 2.5 hours;

[0018] (2) Cool down to room temperature, add 1g of sodium alginate, 1g of gum arabic, 1g of caprolactam and 5ml of glycerol, and stir for 30 minutes at a speed of 400r / min;

[0019] (3) Add 1g polytetrafluoroethylene, 1g chitosan, 0.2g sodium nitrite, 0.1g triethylenetetramine, 0.1g carbonamide, 0.2g benzyl salicylate and 5ml ethanol, and put it into the ultrasonic oscillator Perform ultrasonic oscillation for 20 minutes at an ultrasonic power of 300W;

[0020] (4) Vacuum degassing to remove air bubbles, and use a coating rod to evenly coat it on the wrapping paper with a coating amount of 1.5g / m 2 ;

[0021] (5) Put it in an electric constant temperature blast drying oven to dry for 30 minutes, then place it in a constant temperature and humidit...

Embodiment 2

[0023] A preparation method for antirust, waterproof and oilproof paper, comprising the following steps:

[0024] (1) Mix 3g of stearic acid, 1.5ml of ammonia water and 60ml of distilled water, heat to 70°C and stir for 2.5 hours;

[0025] (2) Cool down to room temperature, add 1.5g sodium alginate, 1.5g gum arabic, 1.5g caprolactam and 6ml glycerol, and stir for 35 minutes at a speed of 450r / min;

[0026] (3) Add 1.5g polytetrafluoroethylene, 1.5g chitosan, 0.25g sodium nitrite, 0.2g triethylenetetramine, 0.15g carbonamide, 0.3g benzyl salicylate and 6ml ethanol, put into ultrasonic vibration Ultrasonic oscillation was performed for 25 minutes at an ultrasonic power of 350W in the instrument;

[0027] (4) Vacuum degassing to remove air bubbles, and use a coating rod to evenly coat it on the wrapping paper with a coating weight of 1.6g / m 2 ;

[0028] (5) Put it in an electric heating constant temperature blast drying oven for 35 minutes and then place it in a constant tempe...

Embodiment 3

[0030] A preparation method for antirust, waterproof and oilproof paper, comprising the following steps:

[0031] (1) Mix 3.5g stearic acid, 1.5ml ammonia water and 75ml distilled water, heat to 70°C and stir for 2.75 hours;

[0032] (2) Cool down to room temperature, add 2g sodium alginate, 1.5g gum arabic, 1.5g caprolactam and 6.5ml glycerol, and stir for 40 minutes at a speed of 500r / min;

[0033] (3) Add 1.5g polytetrafluoroethylene, 1.5g chitosan, 0.25g sodium nitrite, 0.2g triethylenetetramine, 0.15g carbonamide, 0.35g benzyl salicylate and 7.5ml ethanol, put into ultrasonic Perform ultrasonic oscillation for 30 minutes at an ultrasonic power of 350W in an oscillator;

[0034] (4) Vacuum degassing to remove air bubbles, and use a coating rod to evenly coat it on the wrapping paper with a coating weight of 1.6g / m 2 ;

[0035] (5) Put it in an electric heating constant temperature blast drying oven to dry for 40 minutes, then place it in a constant temperature and humid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com