Preparation method of composite molybdate hollow microspheres and application thereof

一种复合钼酸盐、空心微球的技术,应用在化学仪器和方法、催化剂活化/制备、镍化合物等方向,能够解决制备成本高、形貌不可控等问题,达到高孔隙率、高有效接触面积、优越催化活性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Take CuCl 2 Dissolve 1mmol in 20mL of water to obtain solution A; then dissolve 1mmol of molybdic acid in 20mL of water to obtain solution B; mix the two;

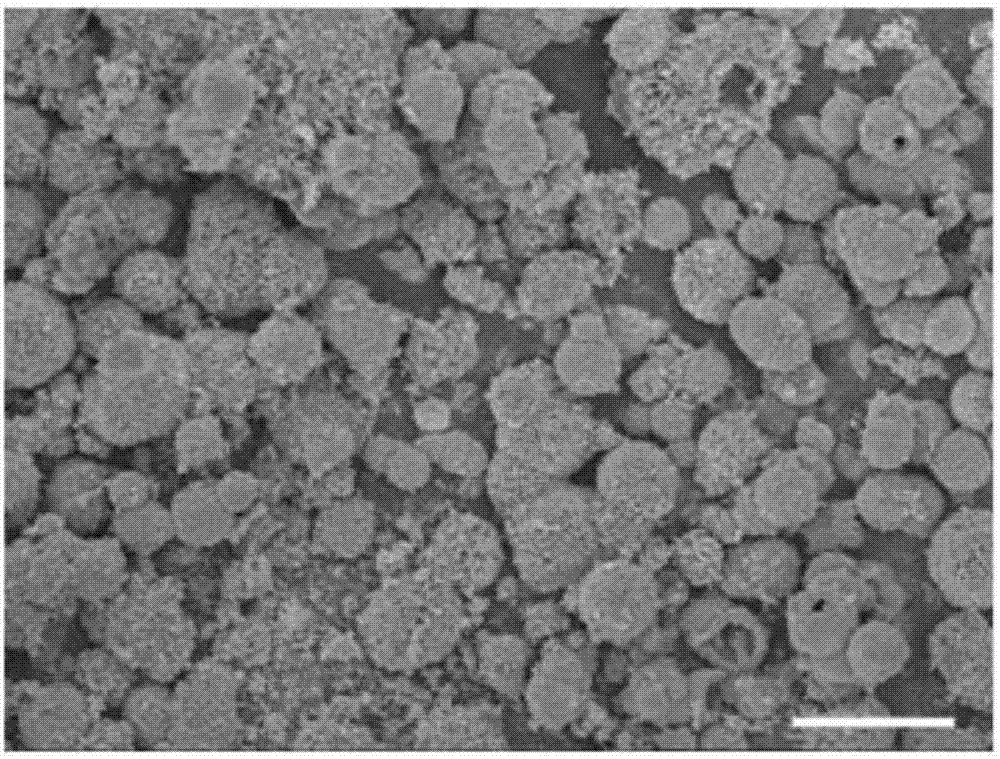

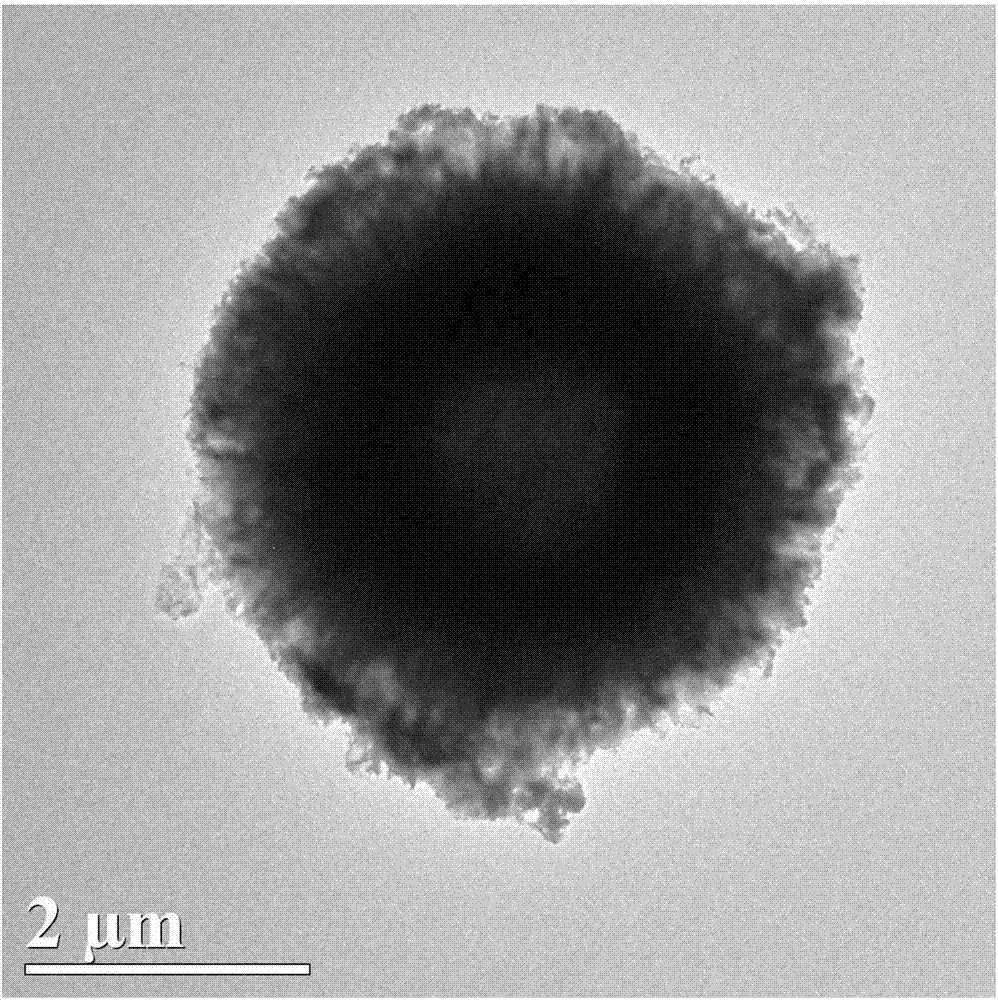

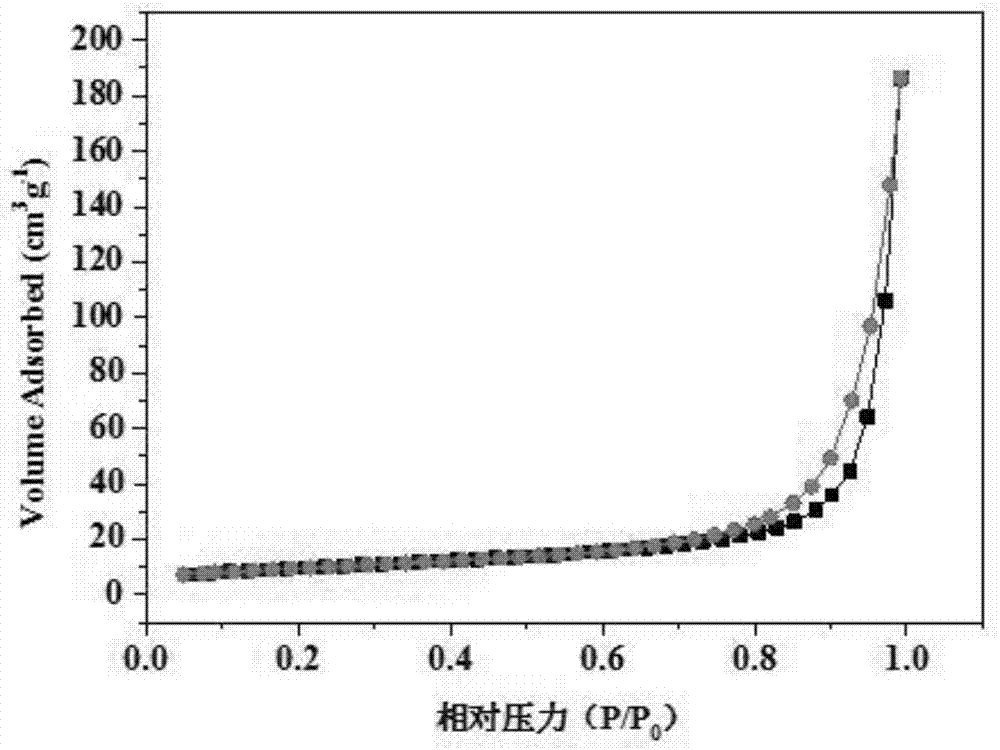

[0027] 2. Dissolve 10mmol urea in 40mL water, add the above solution; stir for 30min, move to the reaction kettle, react at 160°C for 8h; filter and wash with water, dry in a vacuum oven at 40°C; calcinate in a muffle furnace at 500°C for 2h; the sample composition is CuMoO 4 ;

Embodiment 2

[0029] 1. Take CuCl 2 x mmol, NiCl 2 y mmol, CoCl 2 Dissolve (1-x-y)mmol in 20mL water to obtain solution A; then take 2mmol of molybdic acid and dissolve it in 20mL water to obtain solution B; mix the two;

[0030] 2. Take 20mmol of urea and dissolve it in 40mL of water, add the above solution; stir for 30min, move to the reaction kettle, react at 120°C for 12h; filter and wash with water, dry in a vacuum oven at 60°C; calcinate in a muffle furnace at 500°C for 2h; the sample composition is Cu x co y Ni 1-x-y MoO 4 ;

Embodiment 3

[0032] 1. Take CuCl 2 x mmol, NiCl 2 y mmol, CoCl 2 Dissolve (1-x-y)mmol in 20mL water to obtain solution A; then take 2mmol of molybdic acid and dissolve it in 20mL water to obtain solution B; mix the two;

[0033] 2. Dissolve 30mmol of urea in 40mL of water, add the above solution; stir for 30min, move to the reaction kettle, react at 160°C for 8h; filter and wash with water, dry in a vacuum oven at 40°C; calcinate in a muffle furnace for 2h at 350°C; Cu x co y Ni 1-x-y MoO 4 ;

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com