A catalytic cracking method for producing light olefins and light aromatics

A technology of catalytic cracking and low-carbon olefins, applied in chemical instruments and methods, only multi-stage series refining and cracking process treatment, hydrocarbon cracking and hydrocarbon production, etc., can solve problems such as limited and increased yield of light aromatics, and achieve rich Mesoporous structure, high conversion rate, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The preparation method of the catalytic cracking catalyst of the present invention comprises preparing the microsphere composition that comprises Y-type molecular sieve, BEA structure molecular sieve, natural mineral matter, oxide binding agent, and the present invention is called the first composition microsphere, described the first A composition microsphere modification treatment; the first composition microsphere modification treatment comprises the following steps:

[0064] a. Put the microspheres of the first composition into an alkaline solution for treatment, filter and wash to obtain the microspheres of the first composition of alkali treatment;

[0065] b. Treat the alkali-treated first composition microspheres obtained in step a in a compound acid solution composed of fluosilicic acid, organic acid and inorganic acid, filter and wash, optionally exchange ammonium for sodium treatment, and optionally filter and optionally washed, optionally dried, to obtain me...

Embodiment approach

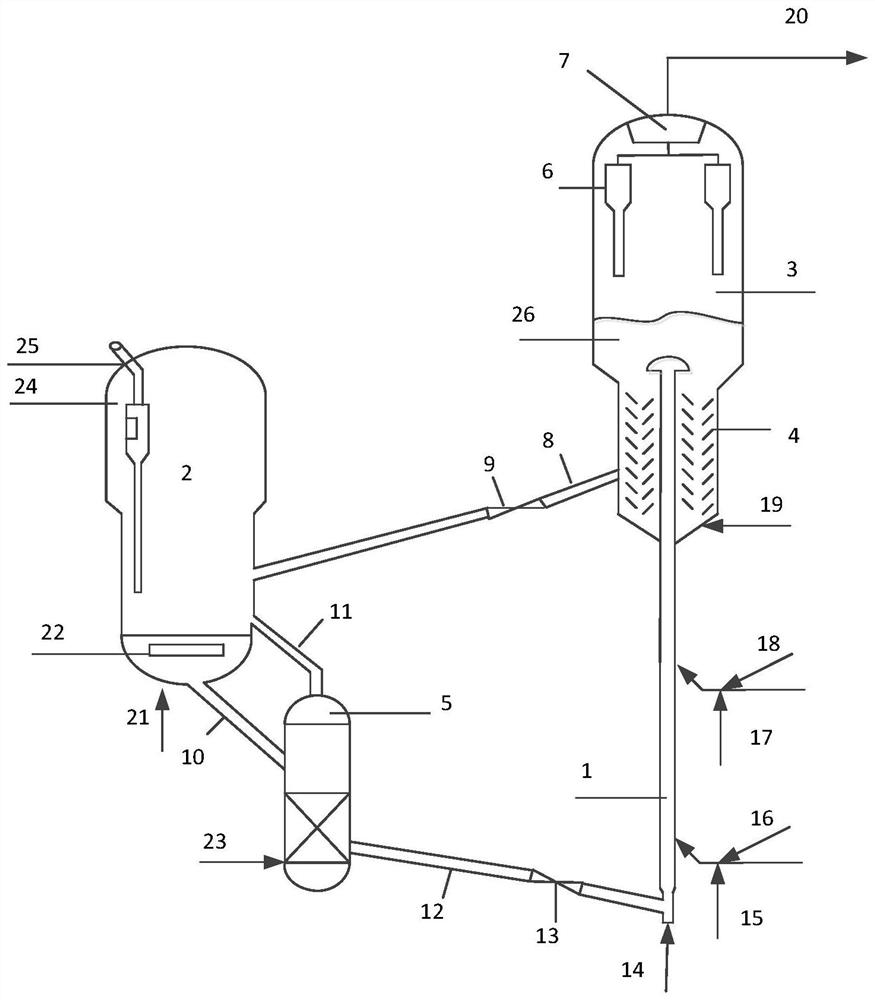

[0086] According to one embodiment of the present invention, when the method of the present invention is carried out in riser reactor, generally carry out as follows:

[0087] The regenerated catalyst (catalyst for catalytic cracking) enters the pre-lift section of the riser reactor and flows upward under the action of the pre-lift medium. The preheated raw oil and atomized steam are injected into the lower part of the riser reactor to contact the regenerated catalyst. The catalytic cracking reaction flows upward at the same time; the reacted oil and gas and the catalyst to be produced enter the fluidized bed reactor through the outlet of the riser reactor, and the reacted oil and gas react again, and the reacted stream enters the cyclone separator through the outlet of the riser reactor, and the separated reaction The oil and gas extraction device is further separated to obtain fractions such as methane, ethylene, propylene, C4 hydrocarbons, and pyrolysis gasoline rich in ligh...

Embodiment 1

[0107] according to figure 1 The flow process of the test is carried out, the raw oil is a vacuum distillate, and the catalyst A of the present invention is used to test on a medium-sized device, operated at normal pressure, and the preheated raw oil enters the bottom of the riser, at a reaction temperature of 545 ° C and a reaction time of 2.0 seconds , the weight ratio of catalytic cracking catalyst and raw oil is 10, and the cracking reaction is carried out under the condition that the weight ratio of water vapor and raw oil is 0.25, and the reaction oil gas and steam and the catalyst to be born enter the fluidized bed reactor from the reactor outlet, and Reaction temperature 530°C, weight hourly space velocity 3.4h -1 The reaction continues under the condition of seconds, and the post-reaction stream enters the closed cyclone, and the reaction oil gas and the unborn catalyst are quickly separated, and the reaction oil gas is cut according to the distillation range in the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| research octane number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com