Polyelectrolyte complex coating and preparation method thereof

A polyelectrolyte and composite technology, which can be used in coatings, devices for coating liquids on surfaces, and surface pretreatment, etc., can solve the problems of low degree of automation, low preparation efficiency, low utilization rate of raw materials, etc., so as to improve the utilization rate. , increase the potential, improve the effect of the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

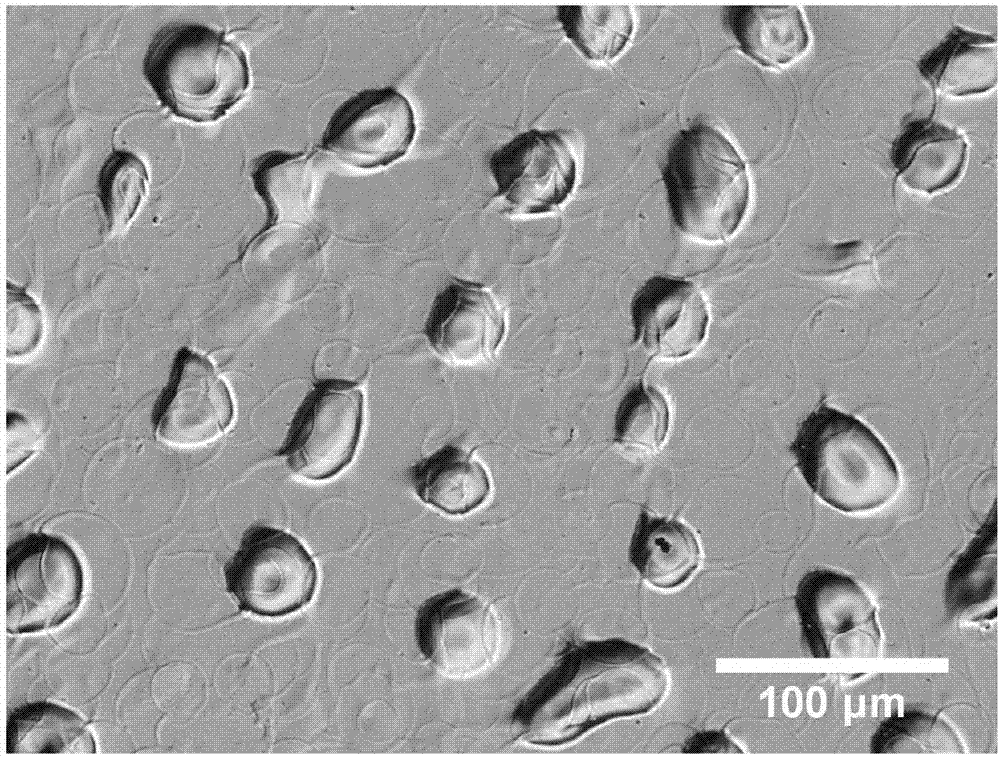

[0041] Preparation of poly-L-lysine / sodium hyaluronate (PLL / HA) composite coating

[0042] (1) Preparation of polyelectrolyte complex stable suspension solution

[0043] Prepare 2 mg / ml sodium hyaluronate (HA, molecular weight 200,000) aqueous solution and 1 mg / ml poly-L-lysine (PLL, molecular weight 70,000) aqueous solution; then, quickly add the PLL aqueous solution dropwise to an equal volume of HA aqueous solution , and stirred rapidly for 1 minute at a stirring speed of 1000 rpm to obtain a PLL / HA complex suspension;

[0044] Next, an equal volume of absolute ethanol to the PLL / HA complex suspension was added and stirred rapidly at 1000 rpm for one minute. Finally, a stable PLL / HA complex suspension was prepared, the particle diameter of the PLL / HA complex nanoparticles was 180 nm, and the surface Zeta potential was -18 mV.

[0045] (2) Primary coating prepared by ultrasonic spraying

[0046] The PLL / HA composite suspension prepared in (1) is atomized and deposited on ...

Embodiment 2

[0053] Preparation of poly-L-lysine / sodium hyaluronate (PLL / HA) composite coating

[0054] (1) Preparation of polyelectrolyte complex stable suspension solution

[0055] Prepare 2 mg / ml sodium hyaluronate (HA, molecular weight 200,000) aqueous solution and 1 mg / ml poly-L-lysine (PLL, molecular weight 70,000) aqueous solution; then, quickly add the PLL aqueous solution dropwise to an equal volume of HA aqueous solution , and stirred rapidly for 1 minute at a stirring speed of 1000 rpm to obtain a PLL / HA complex suspension; the particle diameter of the PLL / HA complex nanoparticles was 210 nm, and the surface Zeta potential was -28 mV.

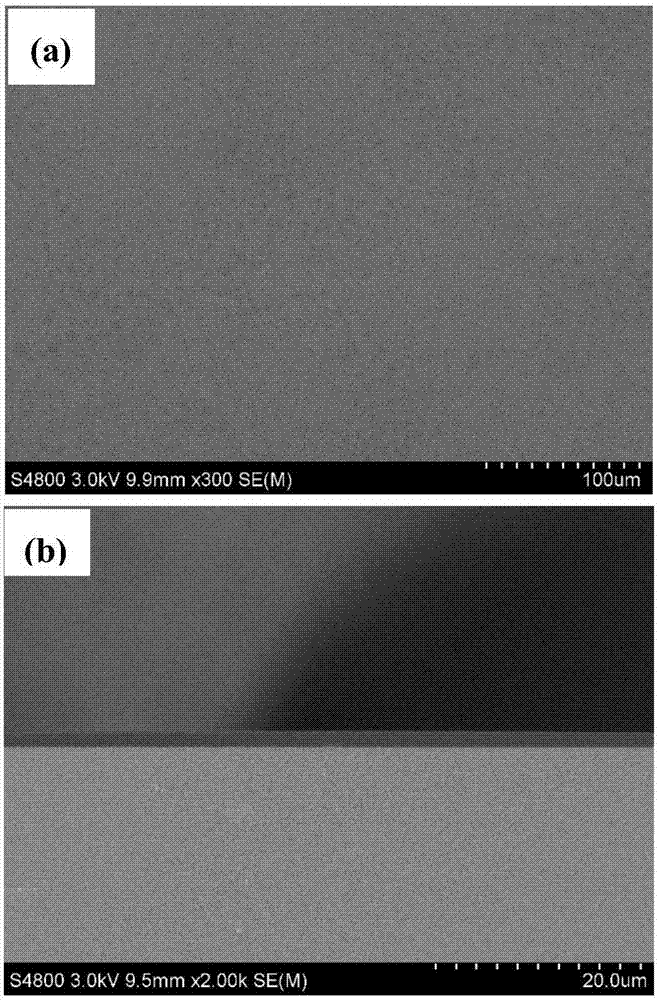

[0056] (2) Primary coating prepared by ultrasonic spraying

[0057] The PLL / HA composite suspension prepared in (1) is atomized and deposited on the surface of the polylactic acid substrate by ultrasonic spraying technology, the frequency of ultrasonic atomization is 100KHz, and the time of ultrasonic atomization spraying is 30 minutes, and the ...

Embodiment 3

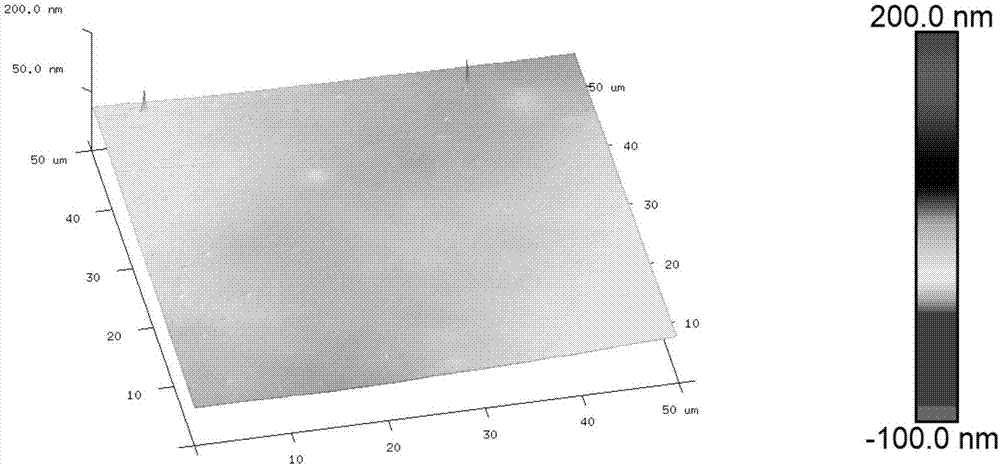

[0061] Preparation of poly-L-lysine / sodium hyaluronate (PLL / HA) composite coating

[0062] (1) Preparation of polyelectrolyte complex stable suspension solution

[0063] Prepare 2 mg / ml sodium hyaluronate (HA, molecular weight 200,000) aqueous solution and 1 mg / ml poly-L-lysine (PLL, molecular weight 70,000) aqueous solution; then, quickly add the PLL aqueous solution dropwise to an equal volume of HA aqueous solution , and stirred rapidly for 1 minute at a stirring speed of 1000 rpm to obtain a PLL / HA complex suspension;

[0064] Next, an equal volume of absolute ethanol to the PLL / HA complex suspension was added and stirred rapidly at 1000 rpm for one minute. Finally, a stable PLL / HA complex suspension was prepared, the particle diameter of the PLL / HA complex nanoparticles was 180 nm, and the surface Zeta potential was -18 mV.

[0065] (2) Spin coating to prepare primary coating

[0066] The PLL / HA composite suspension prepared in (1) was deposited onto the surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com