Method for producing astaxanthin by utilizing phaffia rhodozyma

A technology of Phaffia rhodozyma and astaxanthin, which is applied in the field of microorganisms, can solve the problems of harsh culture conditions, high production cost of astaxanthin, slow growth of Haematococcus pluvialis, etc., so as to increase carbon content and promote the accumulation of astaxanthin. hormone, growth-promoting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

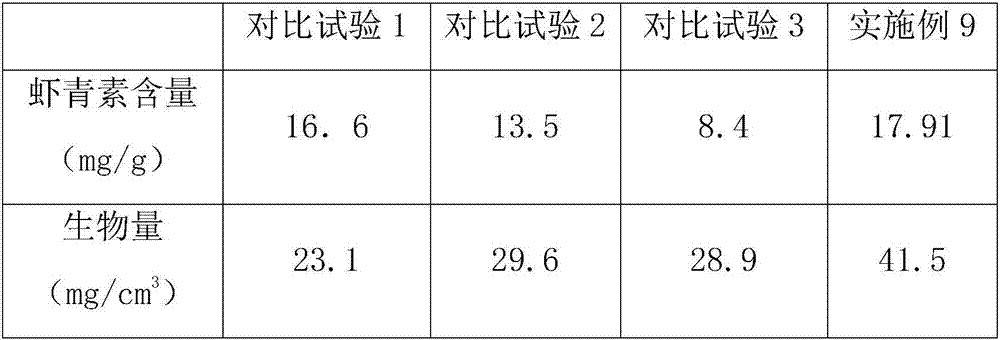

Examples

Embodiment 1

[0022] A method utilizing Phaffia rhodozyme to produce astaxanthin, comprising the following steps:

[0023] 1) Grinding and pulverizing the shrimp waste to obtain a refining liquid, boiling and cooling the refining liquid, adding compound protease and papain for enzymolysis to obtain an enzymatic hydrolysis liquid; adding straw cellulose dry matter, sulfuric acid to the enzymatic hydrolysis liquid Ammonium and molasses are mixed evenly, and the fermentation substrate is obtained after high-pressure steam sterilization;

[0024] 2) inoculating Phaffia rhodozyme into the activation medium, and culturing it in a shaker to obtain activated Phaffia rhodozyme;

[0025] 3) Inoculate the activated Phaffia rhodozyme into the expansion medium, mix it with the fermentation substrate after cultivating for 50 hours under stirring conditions, feed sterile oxygen for continuous cultivation for 50 hours, feed sterile carbon dioxide, oxygen and Mixed gas composed of ethylene, the volume frac...

Embodiment 2

[0028] A method utilizing Phaffia rhodozyme to produce astaxanthin, comprising the following steps:

[0029] 1) Grinding the shrimp scraps with a colloid mill to 300 mesh, boiling and cooling the slurry, adding compound protease and papain for enzymolysis to obtain an enzymolysis solution; adding straw cellulose dry matter, Ammonium sulfate and molasses are mixed evenly, and the fermentation substrate is obtained after high-pressure steam sterilization;

[0030] 2) inoculating Phaffia rhodozyme into the activation medium, and culturing it in a shaker to obtain activated Phaffia rhodozyme;

[0031] 3) Inoculate the activated Phaffia rhodozyme into the expansion medium, mix it with the fermentation substrate after cultivating under stirring conditions for 45 hours, feed sterile oxygen for continuous cultivation for 45 hours, feed sterile carbon dioxide, oxygen and Mixed gas composed of ethylene, the volume fraction ratio of carbon dioxide, oxygen and ethylene is 2:1:0.03, the v...

Embodiment 3

[0034] A method utilizing Phaffia rhodozyme to produce astaxanthin, comprising the following steps:

[0035] 1) Grinding the shrimp scraps with a colloid mill to 300 meshes, boiling and cooling the slurry, adding a compound protease and papain with a mass ratio of 3:1 for enzymolysis to obtain an enzymolysis solution; Add straw cellulose dry matter, ammonium sulfate and molasses, mix evenly, and obtain a fermentation substrate after high-pressure steam sterilization;

[0036] 2) inoculating Phaffia rhodozyme into the activation medium, and culturing it in a shaker to obtain activated Phaffia rhodozyme;

[0037] 3) Inoculate the activated Phaffia rhodozyme into the expansion medium, mix it with the fermentation substrate after cultivating under stirring conditions for 45 hours, feed sterile oxygen for continuous cultivation for 45 hours, feed sterile carbon dioxide, oxygen and Mixed gas composed of ethylene, the volume fraction ratio of carbon dioxide, oxygen and ethylene is 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com