Method for preparing Fe3Al/Cr3C2 composite coating through laser cladding

A technology of laser cladding and composite coating, which is applied in the direction of coating and metal material coating process to achieve the effect of dense structure, good wear resistance and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

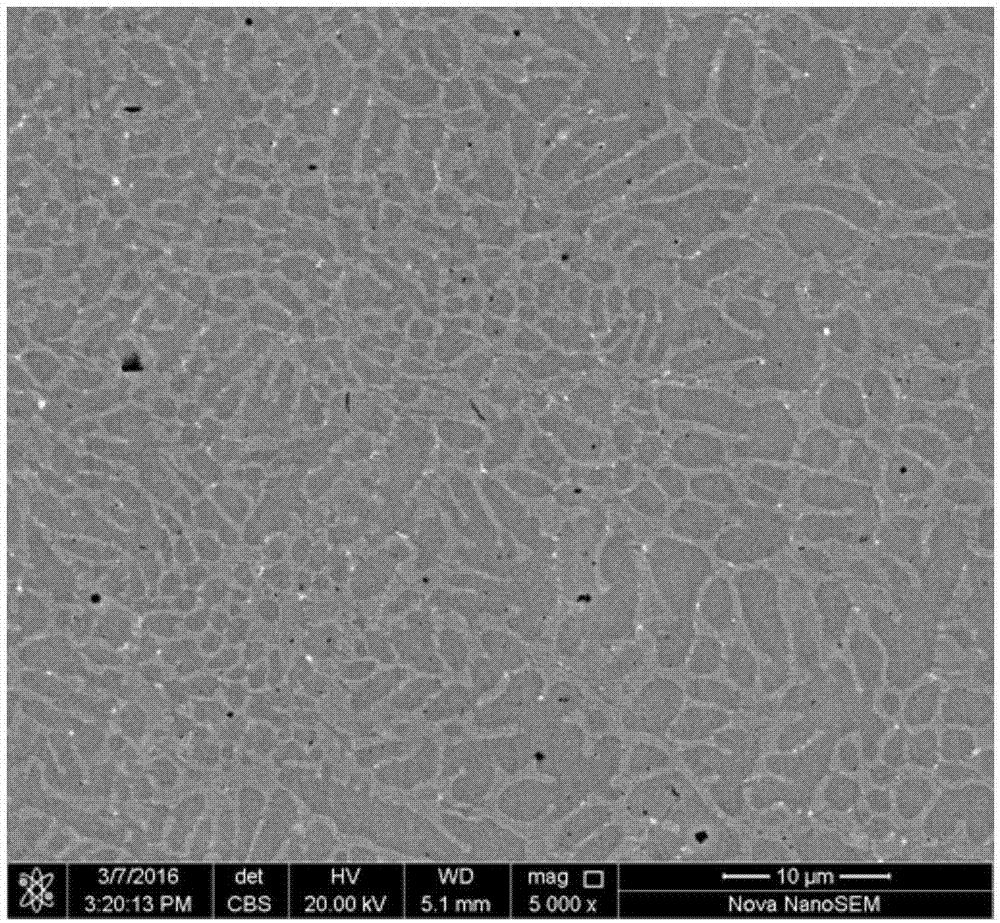

[0024] The surface of 45# steel is pretreated to remove the oil and impurities attached to the surface. in Fe 3 Add 35% Cr in Al powder 3 C 2 Powder, mechanically mixed evenly. Using the coaxial powder feeding method, the evenly mixed Fe 3 Al / Cr 3 C 2The powder is sent to the surface of the substrate. Fiber laser is used for laser cladding, the laser cladding power is 2100W, the scanning speed is 0.3m / min, the laser rectangular spot size is 5×5mm, the overlapping amount is 2mm, and the powder feeding amount is 25g / min. The protective gas for laser cladding is argon, with a flow rate of 25L / min. Fe obtained by laser cladding 3 Al / Cr 3 C 2 The thickness of the composite coating is about 1.5mm, the average hardness of the coating is 720HV, and the microstructure is as follows figure 1 As shown, the in situ self-generated iron and chromium complex carbides are distributed in the Fe 3 Al / Cr 3 C 2 in composite coatings. As a comparative method, the same laser cladding...

Embodiment 2

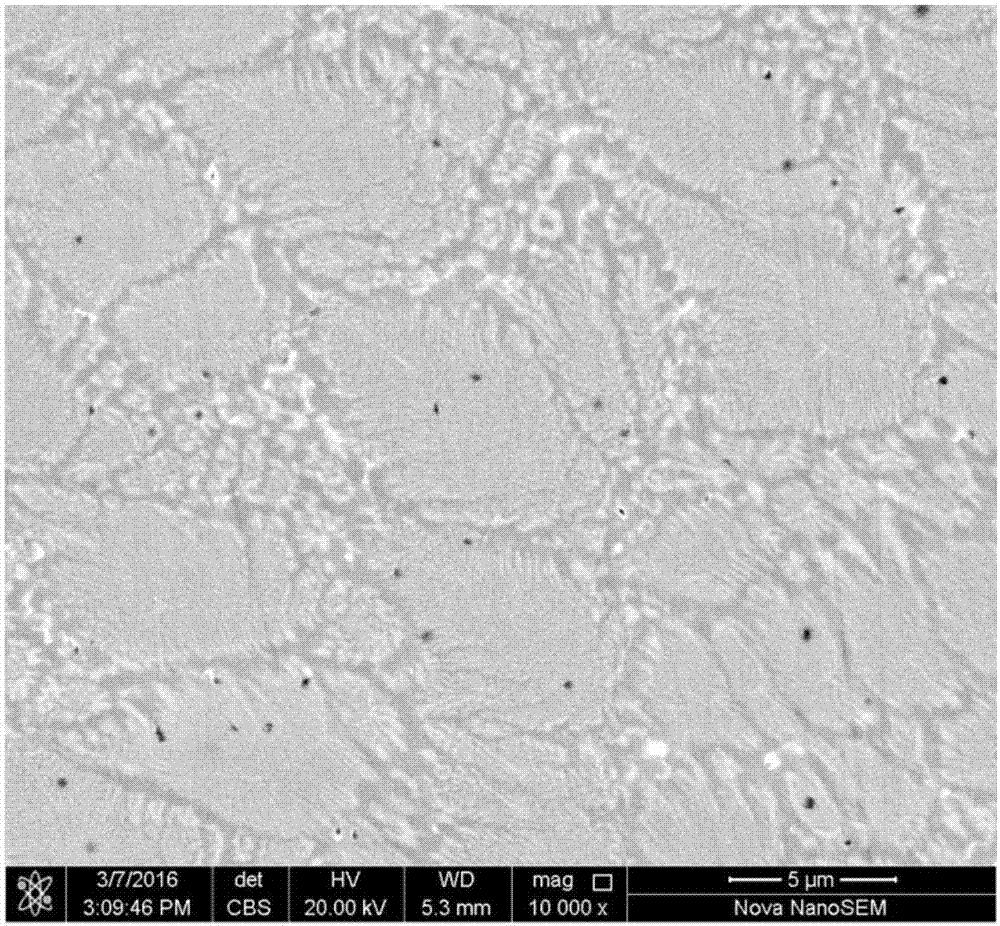

[0026] Pre-treat the surface of heat-resistant stainless steel to remove oil and impurities attached to the surface. in Fe 3 Add 25% Cr in Al powder 3 C 2 Powder, mechanically mixed evenly. Using the coaxial powder feeding method, the evenly mixed Fe 3 Al / Cr 3 C 2 The powder is sent to the surface of the substrate. Fiber laser is used for laser cladding, the laser cladding power is 1600W, the scanning speed is 0.18m / min, the diameter of the laser circular spot is 3mm, and the powder feeding amount is 20g / min. The protective gas for laser cladding is argon, with a flow rate of 20L / min. Fe obtained by laser cladding 3 Al / Cr 3 C 2 The thickness of the composite coating is 1.2mm, the average hardness of the coating is 630HV, and the microstructure is as follows image 3 shown. Under the dry friction conditions of load 8MPa and temperature 300℃ (surface friction, the grinding material is gray cast iron), laser cladding Fe 3 Al / Cr 3 C 2 The wear rate of the composite ...

Embodiment 3

[0028] The surface of vermicular graphite cast iron is pretreated to remove oil and impurities attached to the surface. in Fe 3 Add 15% Cr in Al powder 3 C 2 Powder, mechanically mixed evenly. Using side shaft powder feeding method, the mixed Fe 3 Al / Cr 3 C 2 The powder is sent to the surface of the substrate. Fiber laser is used for laser cladding, the laser cladding power is 1500W, the scanning speed is 0.36m / min, the laser rectangular spot size is 2.5×10mm, and the powder feeding volume is 15g / min. The protective gas for laser cladding is argon, with a flow rate of 15L / min. Fe obtained by laser cladding 3 Al / Cr 3 C 2 The thickness of the composite coating is 0.8mm, and the average hardness of the coating is 560HV. Under the condition of dry friction with a load of 5MPa (surface friction, the grinding material is gray cast iron), laser cladding Fe 3 Al / Cr 3 C 2 The wear rate of the composite coating is 0.47×10 ‐5 mm 3 / N m, with good wear resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com