Solid beverage containing omega-7 fatty acid and preparation method of beverage

A technology of solid beverages and fatty acids, which is applied in dairy products, milk preparations, applications, etc., to facilitate processing and transportation, meet the convenience of eating, and solve the effects of instability of high-content omega-7 fatty acids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Formula of solid beverage containing omega-7 fatty acid:

[0035]α-linolenic acid 1.2kg, omega-7 fatty acid 0.5kg, TBHQ 0.28g, sodium caseinate 2.2kg, lecithin 0.3kg, soybean protein peptide powder 2.1kg, skimmed milk powder 7.1kg, sweet orange powder 0.66kg, sweet Orange essence 0.05kg, fructose 0.15kg.

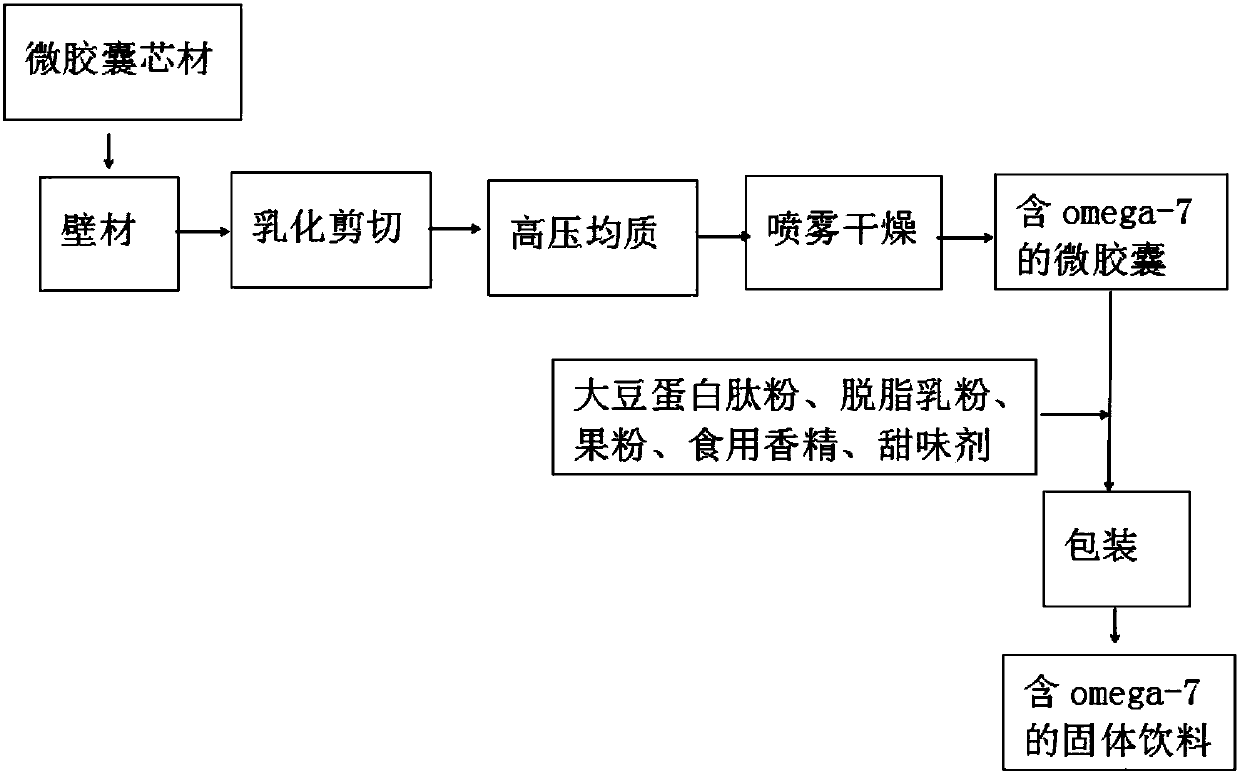

[0036] 2. The preparation method of the solid beverage containing omega-7 fatty acid, such as figure 1 Shown:

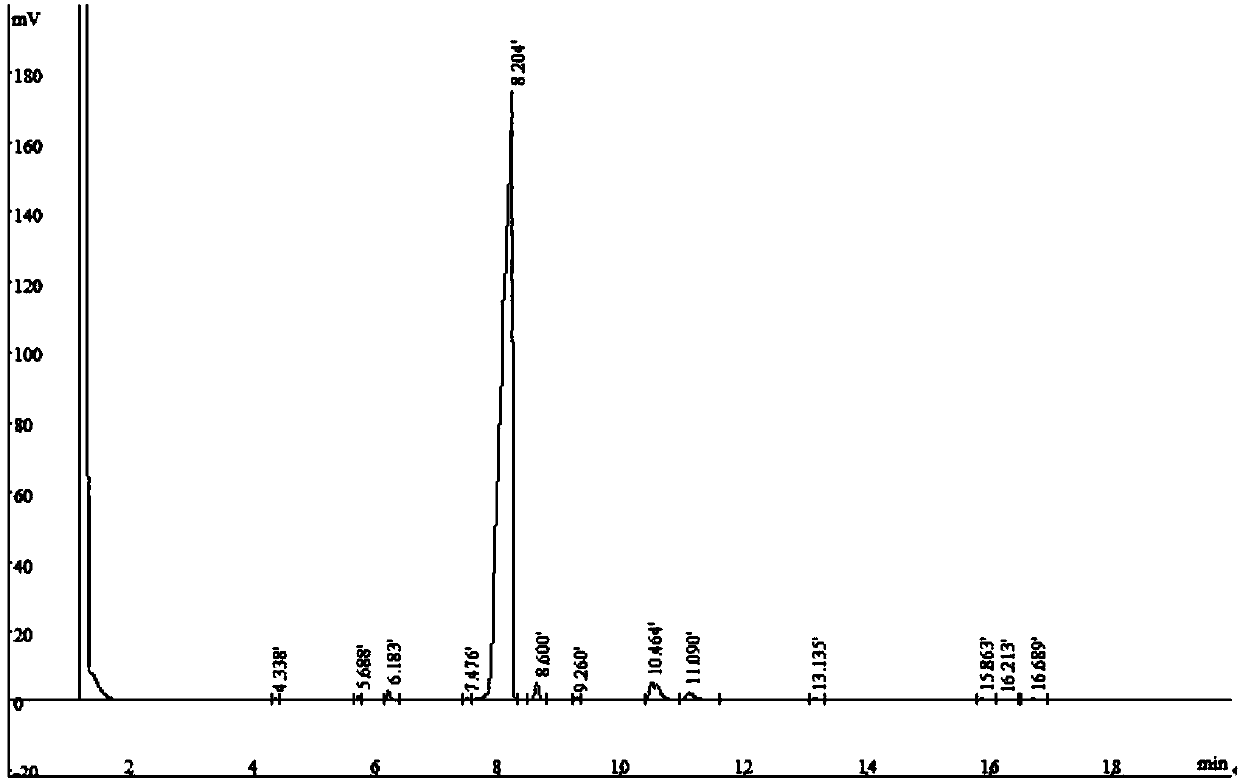

[0037] (1) Weigh 1.2kg of α-linolenic acid, 0.5kg of omega-7 fatty acid and 0.28g of TBHQ, and stir evenly at a temperature of 15-40°C under nitrogen protection to obtain a microcapsule core material. Another weighed 2.2kg of sodium caseinate and 0.3kg of lecithin were added to 4.0kg of water, heated to 62-65°C under nitrogen protection, kept warm and stirred rapidly for 40 minutes, and then slowly cooled to 25-30°C to obtain the wall material of the microcapsules. Among them, the purity of omega-7 fatty acid is ≥90%, and its gas chromatogram is as fol...

Embodiment 2

[0043] 1. Formula of solid drink containing omega-7 fatty acids:

[0044] α-linolenic acid 2.0kg, omega-7 fatty acid 0.84kg, ascorbyl palmitate 0.5g, sodium caseinate 2.0kg, soybean protein isolate 1.7kg, monoglyceride 0.5kg, soybean protein peptide powder 3.5kg, skim milk powder 11.8kg, strawberry fruit powder 1.0kg, strawberry essence 0.1kg, sucralose 0.35kg.

[0045] 2. The preparation method of the solid beverage containing omega-7 fatty acid

[0046] (1) Weigh 2.0kg of α-linolenic acid, 0.84kg of omega-7 fatty acid and 0.5g of ascorbyl palmitate, and stir evenly at a temperature of 15-40°C under the protection of nitrogen to obtain a microcapsule core material. Another weighed 2.0kg of sodium caseinate, 1.7kg of soybean protein isolate, and 0.5kg of monoglyceride were added to 7.0kg of water, heated to 65°C under nitrogen protection, kept warm and stirred rapidly for 45 minutes, and then slowly cooled to 25-30°C to obtain micro Capsule wall material.

[0047] (2) Under...

Embodiment 3

[0052] 1. Formula of solid drink containing omega-7 fatty acids:

[0053] α-linolenic acid 2.0kg, omega-7 fatty acid 0.84kg, ascorbyl palmitate 0.2g, sodium caseinate 2.7kg, soybean protein isolate 1.0kg, rosemary extract 1.2g, monoglyceride 0.5kg, soybean protein Peptide powder 3.5kg, skimmed milk powder 11.8kg, jujube paste fruit powder 1.2kg, jujube paste essence 0.12kg, aspartame 0.10kg.

[0054] 2. The preparation method of the solid beverage containing omega-7 fatty acid

[0055] (1) Weigh 2.0kg of α-linolenic acid, 0.84kg of omega-7 fatty acid and 0.2g of ascorbyl palmitate, and stir evenly at a temperature of 15-40°C under the protection of nitrogen to obtain a microcapsule core material. Add 2.7kg of sodium caseinate, 1.0kg of soybean protein isolate, 1.2g of rosemary extract, and 0.5kg of monoglyceride into 7.0kg of water, heat up to 65°C under nitrogen protection, keep stirring quickly for 45 minutes, and then slowly cool down to 25-30°C to obtain the wall materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com