Preparation method of bismuthyl carbonate-graphene oxide nanocomposite

A nano-composite, bismuth oxycarbonate technology, applied in the directions of carbon compounds, bismuth compounds, chemical instruments and methods, etc., achieves the effects of safe and reliable operation, easy industrial production, and improved product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] According to the molar ratio of 1:1, 0.01 moles of sodium bismuth dihydrate, 0.01 moles of oxalic acid dihydrate and 0.1 g of graphene oxide nanosheets were weighed and added to a 50 zirconia grinding balls with a diameter of 6 mm and 8 zirconia grinding balls with a diameter of 10 mm. In a 50mL zirconia ball mill, in a QM-3SP04 planetary high-energy ball mill at 480rpm for 2 hours, the product was washed with distilled water, centrifuged and vacuum-dried at 60°C and 0.1Mpa vacuum for 2 hours to obtain the target product.

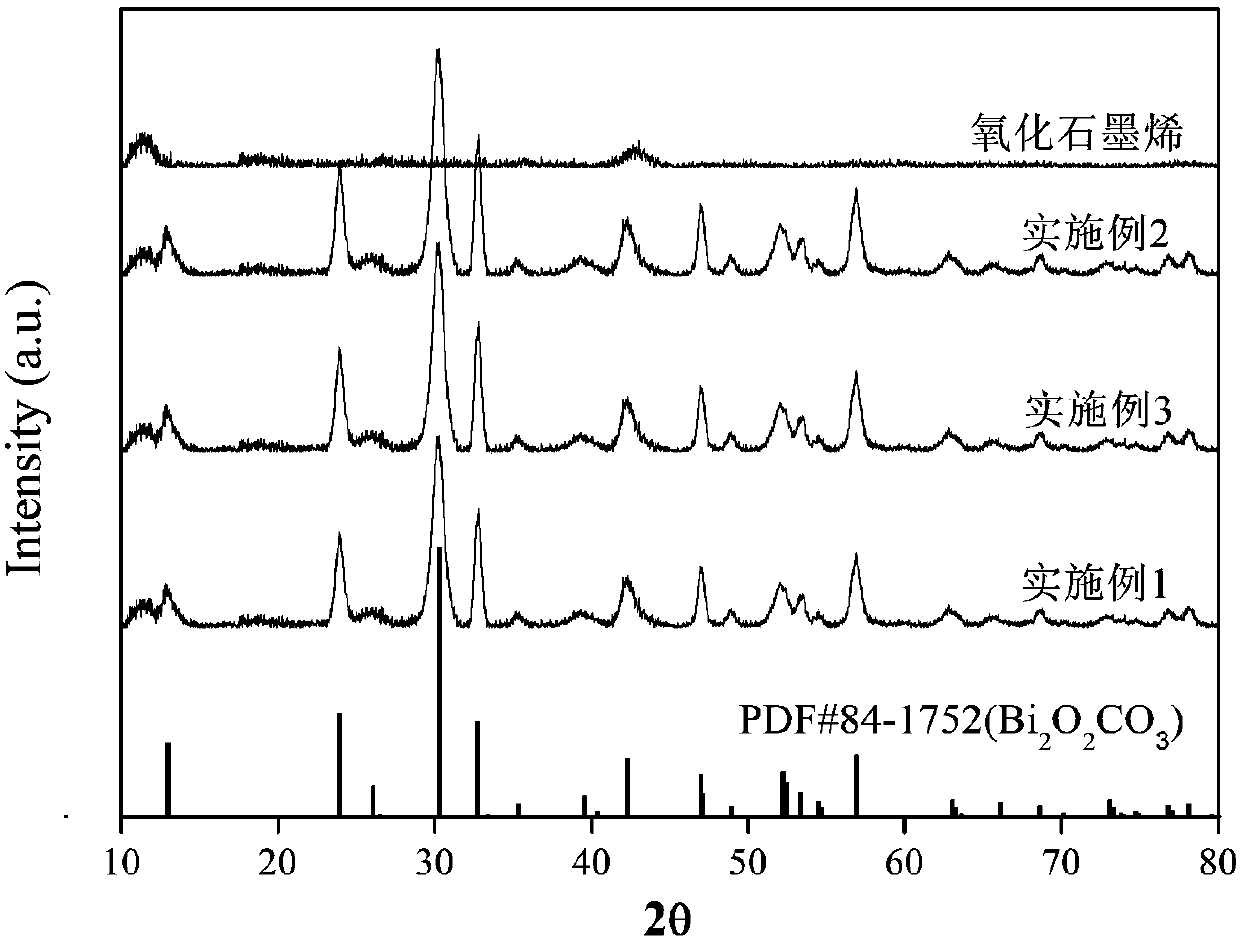

[0025] XRD analysis of the product (see appendix figure 1 ), only Bi in the XRD pattern 2 O 2 CO 3 Characteristic diffraction peaks and weak graphene oxide diffraction peaks, no diffraction peaks of other phases exist, indicating that the solid-phase reaction between sodium bismuth and oxalic acid dihydrate is complete after 2.0 hours of ball milling. Calculated according to the Scherrer formula, Bi in the product 2 O 2 CO 3 The average grain ...

Embodiment 2

[0027]According to the molar ratio of 1:1, 0.01 moles of sodium bismuth dihydrate, 0.01 moles of oxalic acid dihydrate and 0.1 g of graphene oxide nanosheets were weighed and added to a 50 zirconia grinding balls with a diameter of 6 mm and 8 zirconia grinding balls with a diameter of 10 mm. In a 50mL zirconia ball mill, in a QM-3SP04 planetary high-energy ball mill at 480rpm for 10 hours, the product was washed with distilled water, centrifuged and vacuum-dried at 60°C and 0.1Mpa vacuum for 2 hours to obtain the target product.

[0028] The product was analyzed by XRD and calculated according to the Scherrer formula. Bi in the product 2 O 2 CO 3 The average grain size is 17.6 nm.

Embodiment 3

[0030] According to the molar ratio of 1:1, 0.01 moles of sodium bismuth dihydrate, 0.01 moles of oxalic acid dihydrate and 0.1 g of graphene oxide nanosheets were weighed and added to a 50 zirconia grinding balls with a diameter of 6 mm and 8 zirconia grinding balls with a diameter of 10 mm. In a 50mL zirconia ball mill, in a QM-3SP04 planetary high-energy ball mill at 480rpm for 4 hours, the product was washed with distilled water, centrifuged and vacuum-dried at 60°C and 0.1Mpa vacuum for 2 hours to obtain the target product.

[0031] The product was analyzed by XRD and calculated according to the Scherrer formula. Bi in the product 2 O 2 CO 3 The average grain size is 16.1 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com