Flame-retardant polyurethane elastomer material for furniture and preparation method thereof

A technology of polyurethane elastomer and flame retardancy, which is applied in the field of polyurethane materials, can solve the problems of large heat release, flammability, dripping and dripping, etc., and achieve the goal of improving flame retardancy, good flame retardancy, and reducing adverse effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

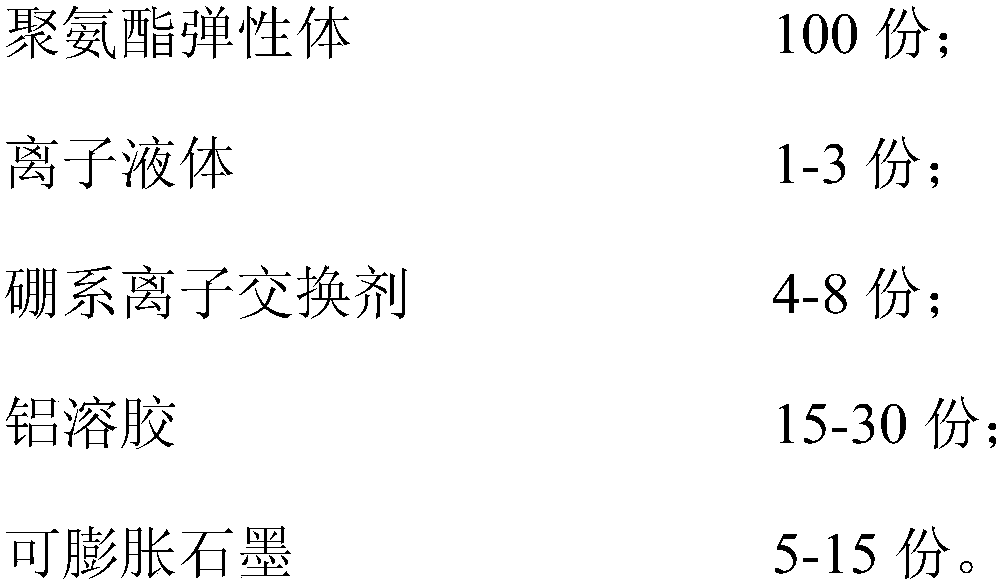

[0043] A flame-retardant polyurethane elastomer material for furniture, comprising the following raw material components in parts by mass:

[0044]

[0045] Wherein, the ionic liquid is 1-ethyl-3-methylimidazolium hexafluorophosphate, the boron ion exchanger is boric acid, the concentration of aluminum sol is 20wt%, and the particle diameter of expandable graphite is 500nm.

[0046] The preparation method of above-mentioned flame-retardant polyurethane elastomer material is as follows:

[0047] (1) According to the formula, mix the ionic liquid, boron-based ion exchanger, aluminum sol and expandable graphite at a stirring rate of 300r / min for 24h, adjust the pH to 7.5, and react at 100°C for 3h;

[0048] (2) centrifuging the mixed solution obtained in step (1), then washing and drying;

[0049] (3) Add the solid content obtained in step (2) and the polyurethane elastomer into an internal mixer, and melt and blend at 150° C. for 30 minutes to obtain the above-mentioned flam...

Embodiment 2

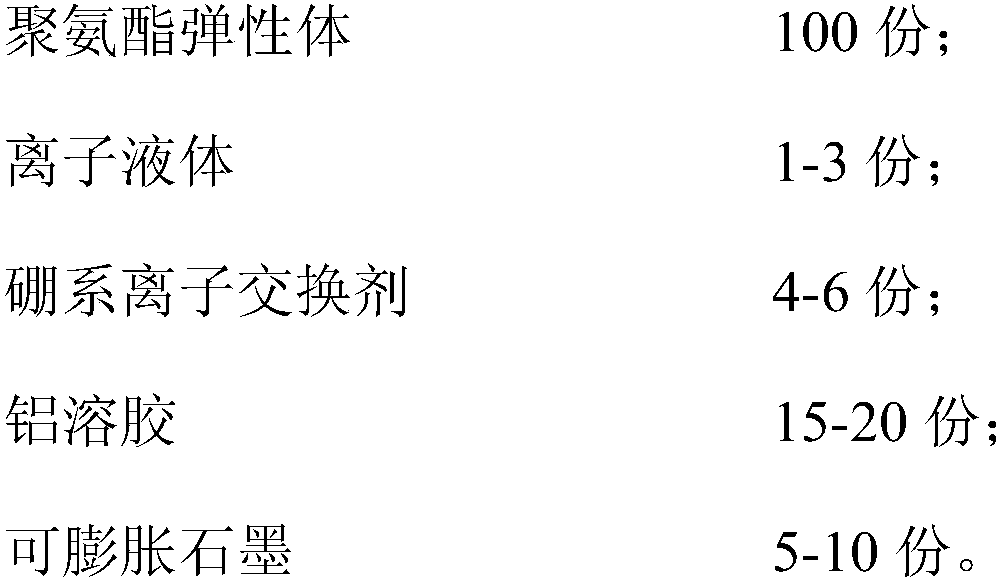

[0051] A flame-retardant polyurethane elastomer material for furniture, comprising the following raw material components in parts by mass:

[0052]

[0053] Wherein, the ionic liquid is 1-ethyl-3-methylimidazolium tetrafluoroborate, the boron ion exchanger is sodium metaborate, the concentration of aluminum sol is 30wt%, and the particle size of expandable graphite is 10 μm.

[0054] The preparation method of above-mentioned flame-retardant polyurethane elastomer material is as follows:

[0055] (1) According to the formula, mix the ionic liquid, boron-based ion exchanger, aluminum sol and expandable graphite at a stirring rate of 500r / min for 12h, adjust the pH to 9, and react at 80°C for 6h;

[0056] (2) centrifuging the mixed solution obtained in step (1), then washing and drying;

[0057] (3) Add the solid content obtained in step (2) and the polyurethane elastomer into an internal mixer, and melt and blend at 180° C. for 15 minutes to obtain the above-mentioned flame-...

Embodiment 3

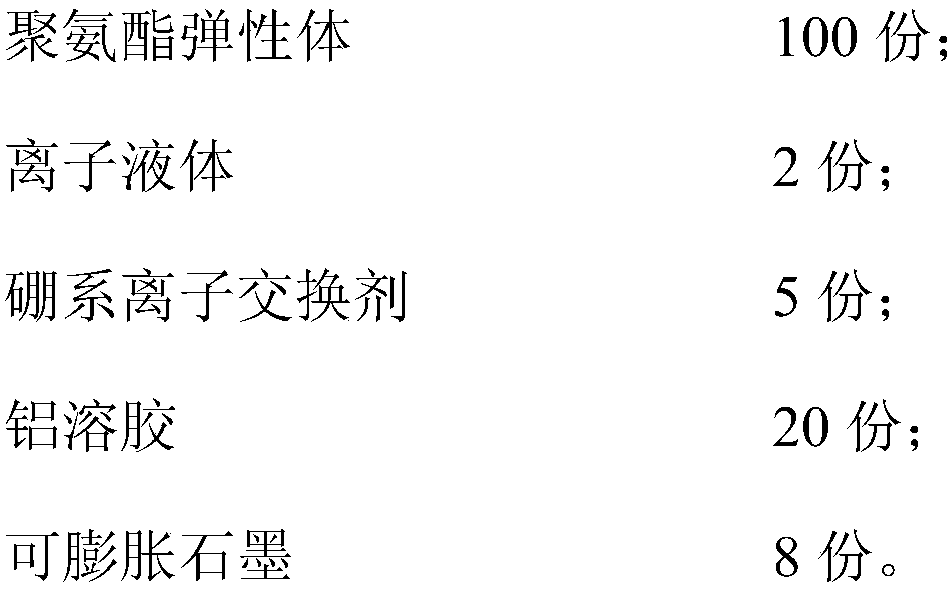

[0059] A flame-retardant polyurethane elastomer material for furniture, comprising the following raw material components in parts by mass:

[0060]

[0061]

[0062] Wherein, the ionic liquid is 1-methyl-3-ethylimidazole chloride, the boron ion exchanger is sodium metaborate, the concentration of aluminum sol is 28wt%, and the particle diameter of expandable graphite is 800nm.

[0063] The preparation method of above-mentioned flame-retardant polyurethane elastomer material is as follows:

[0064] (1) According to the formula, mix the ionic liquid, boron-based ion exchanger, aluminum sol and expandable graphite at a stirring rate of 350r / min for 20h, adjust the pH to 8, and react at 90°C for 4h;

[0065] (2) centrifuging the mixed solution obtained in step (1), then washing and drying;

[0066] (3) Add the solid content obtained in step (2) and the polyurethane elastomer into an internal mixer, and melt and blend at 170° C. for 20 minutes to obtain the above-mentioned f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap