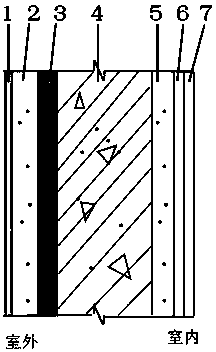

Wall internal and external combination heat-preservation system

A technology for thermal insulation systems and walls, applied in thermal insulation, climate sustainability, reflection/signal coatings, etc., can solve the problems of not fully achieving building thermal insulation and energy saving, fire hazards of organic thermal insulation materials, and increasing the overall building weight, etc. Achieve the effect of good thermal insulation effect, low thermal conductivity and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] 1. Preparation of architectural reflective thermal insulation coatings, taking the preparation of 100kg architectural reflective thermal insulation coatings as an example.

[0095] Water 22kg Cellulose 0.2kg Neutralizer 0.3kg Dispersant 0.8kg Defoamer 0.4kg Antifreeze 2kg Fungicide 0.2kg Titanium Dioxide 19kg Thickener 0.45kg Hollow glass beads 10kg

[0096] A preparation method of architectural reflective heat-insulating paint has the following steps: firstly inject 22kg of water into a dispersing kettle, stir 0.2kg of cellulose evenly in the water, and then sequentially add 0.3kg of neutralizer, 0.8kg of dispersant, 0.4kg of kg defoamer, 2kg antifreeze, 0.2kg bactericide, adjust the speed of the disperser to a low speed for stirring, and disperse to a uniform state; then add 19 kg titanium dioxide, 7.4 kg talc, and 3.5 kg reflective pigment, and disperse at a high speed to a suitable level Fineness; then put in 32kg of silicone-acrylic emulsion, 1.75kg of film-formin...

Embodiment 2

[0115] 1. Preparation of architectural reflective thermal insulation coatings, taking the preparation of 1000kg architectural reflective thermal insulation coatings as an example.

[0116] Water 20kg Cellulose 0.2kg Neutralizer 0.3kg Dispersant 0.75kg Defoamer 0.4kg Antifreeze 2kg Bactericide 0.2kg Titanium Dioxide 20kg 0.45kg hollow glass beads 10kg

[0117]A preparation method of architectural reflective heat-insulating paint has the following steps: firstly inject 20kg of water into a dispersing kettle, stir 0.2kg of cellulose evenly in the water, and then sequentially add 0.3kg of neutralizer, 0.75kg of dispersant, 0.4kg of kg defoamer, 2kg antifreeze, 0.2kg bactericide, adjust the speed of the disperser to a low speed for stirring, and disperse to a uniform state; then add 20kg titanium dioxide, 6.4kg talc, and 3.5kg reflective pigment, and disperse at high speed to a suitable fineness Then put in 34kg of silicone-acrylic emulsion, 1.8kg of film-forming aids and 0.45kg o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com