A kind of preparation method of polymer flexible conductive film

A polymer film, flexible conductive technology, used in printed circuit manufacturing, printed circuits, electrical components and other directions, can solve the problems of complex manufacturing process, damage to electronic equipment, reduce the breakdown voltage tolerance of circuit boards, etc. The effect of folding, eliminating internal stress, enhancing voltage breakdown performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

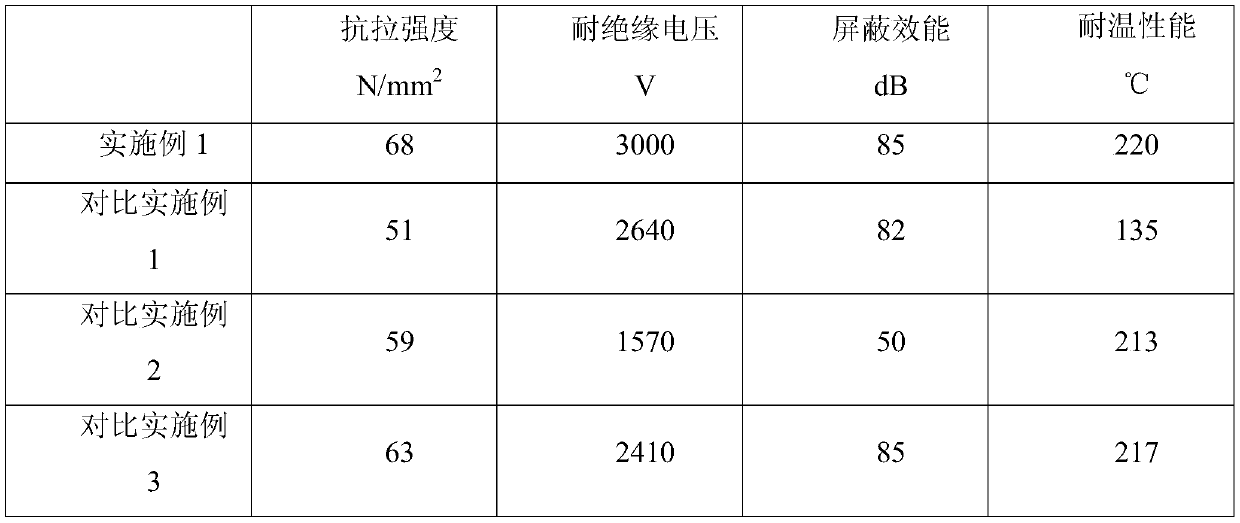

Examples

Embodiment 1

[0026] A preparation method of polymer flexible conductive film:

[0027] (1) Roughen the PP film with a thickness of 1um in lye solution (60% by weight of sodium hydroxide, 40% by weight of ethylene glycol) for 30 minutes at 60°C, wash and dry it;

[0028] (2) Carry out heat-bonding laser pattern etching to the polymer film processed through step (1),

[0029] The laser power is 20Kw, the laser beam width is 0.4um, the etching speed is 15mm / min, the etching depth is 1 / 3 of the thickness of the substrate, and the heat treatment temperature of the whole film is 180℃ while the laser is in use;

[0030] (3) Brush the strongly acidic mixed solution of ferrous chloride and ferrous sulfate (ferrous ion concentration is 7mol / L) in the lines obtained in step (2), and after drying, immerse the polymer film in 0.5mol / L Fully soak in the silver nitrate solution of L, so that the etched texture surface of the polymer film is covered with a 0.1um conductive layer;

[0031] (4) on the con...

Embodiment 2

[0035] A preparation method of polymer flexible conductive film:

[0036] (1) Roughen the PE film with a thickness of 5um in lye solution (70% by weight of sodium hydroxide, 30% by weight of ethylene glycol) for 40 minutes at 70°C, wash and dry it;

[0037] (2) Carry out heat-bonding laser pattern etching to the polymer film processed through step (1),

[0038] The laser power is 20Kw, the laser beam width is 0.4um, the etching speed is 15mm / min, the etching depth is 1 / 3 of the thickness of the substrate, and the heat treatment temperature of the whole film is 180℃ while the laser is in use;

[0039] (3) Brush the strongly acidic mixed solution of ferrous chloride and ferrous sulfate (the ferrous ion concentration is 6mol / L) in the lines obtained in step (2), and after drying, immerse the polymer film in 0.2mol / L Fully soak in the silver nitrate solution of L, so that the etched texture surface of the polymer film is covered with a 0.3um conductive layer;

[0040] (4) on the...

Embodiment 3

[0044] A preparation method of polymer flexible conductive film:

[0045] (1) Roughen the PVC film with a thickness of 8um in lye solution (80% by weight of sodium hydroxide, 20% by weight of ethylene glycol) for 60 minutes at 80°C, clean and dry;

[0046] (2) Carry out heat-bonding laser pattern etching to the polymer film processed through step (1),

[0047] The laser power is 20Kw, the width of the laser beam is 0.4um, the etching speed is 15mm / min, the etching depth is 2 / 3 of the thickness of the substrate, and the heat treatment temperature of the whole film is 180℃ while the laser is in use;

[0048] (3) Brush the strongly acidic mixed solution of ferrous chloride and ferrous sulfate (the ferrous ion concentration is 10mol / L) in the lines obtained in step (2), and after drying, immerse the polymer film in 0.5mol / L Fully soak in the silver nitrate solution of L, so that the etched texture surface of the polymer film is covered with a 0.6um conductive layer;

[0049](4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com