Burnt magnesite brick for replacing paper pulp by dextrose monohydrate and production method of burnt magnesite brick

A technology of glucose and pulp, applied in the field of refractory materials, can solve the problems of polluting the atmosphere, environmental damage, increasing the loss of desulphurization equipment, etc., and achieves the effects of cost saving, sintering promotion and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with embodiment the present invention is further described:

[0020] The following examples describe the present invention in detail. These examples are only to describe the best embodiment of the present invention, and do not limit the scope of the present invention.

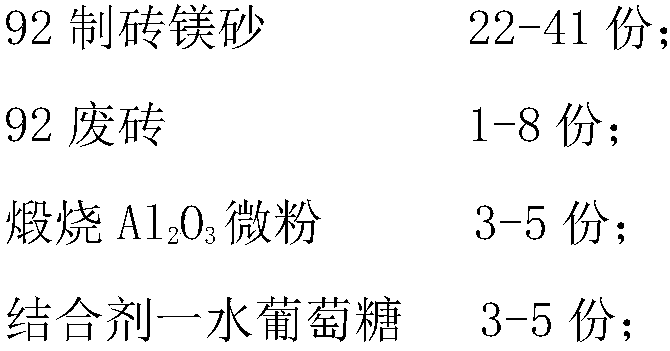

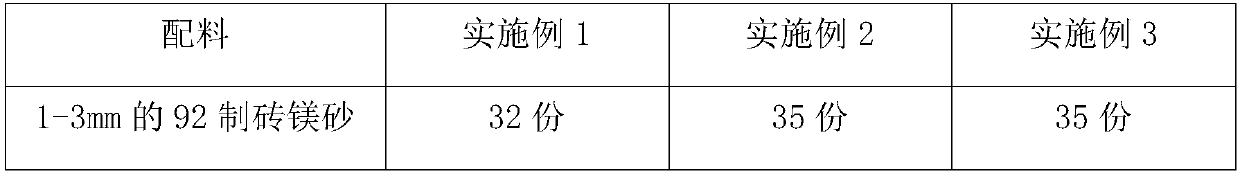

[0021] Embodiment 1-3 is provided below, and the formula of the fired magnesia brick of paper pulp is replaced as shown in table 1 with glucose monohydrate:

[0022] Table 1 embodiment 1-3 takes 92 brick-making magnesia as the formula of main raw material making gunning material

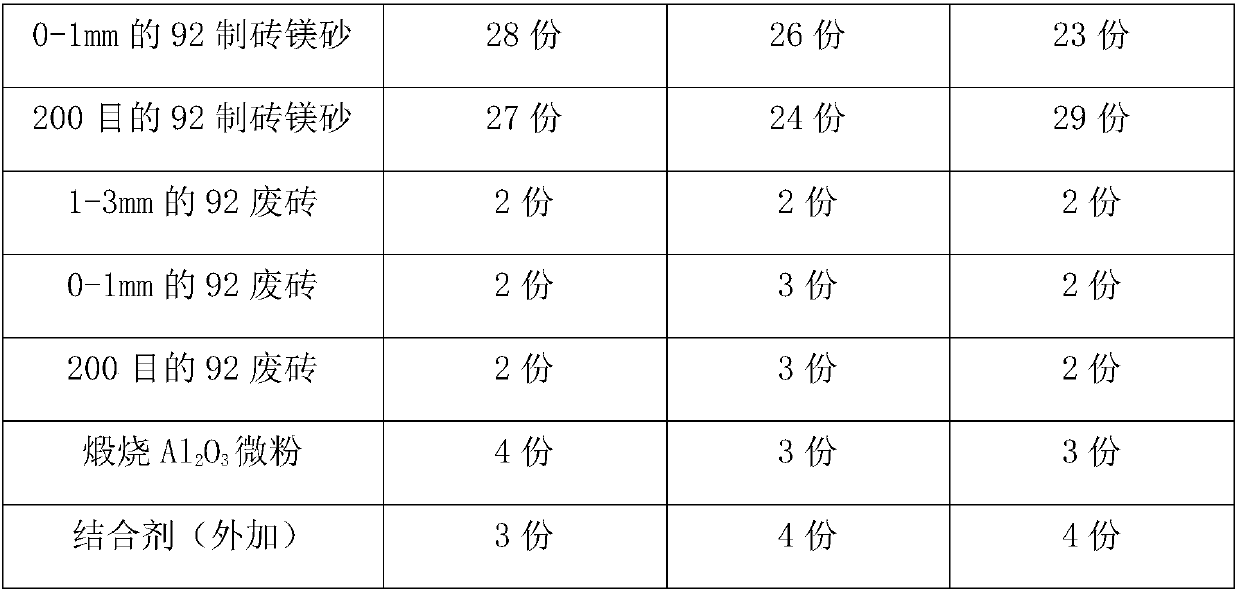

[0023]

[0024]

[0025] The main raw material indicators are shown in Table 2:

[0026] Table 2 main raw material index

[0027]

[0028] The production method of the burnt magnesia brick that replaces paper pulp with glucose monohydrate of above-mentioned embodiment 1-3, comprises the following steps:

[0029] 1) Crushing, screening and fine grinding of raw materials:

[0030] The 92 brick-m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com