Method for synergistically catalyzing one-step conversion of cellulose into 1,4-sorbitan

A sorbitol, synergistic catalysis technology, applied in the field of catalysis, to avoid corrosion and environmental problems, inhibit side reactions, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

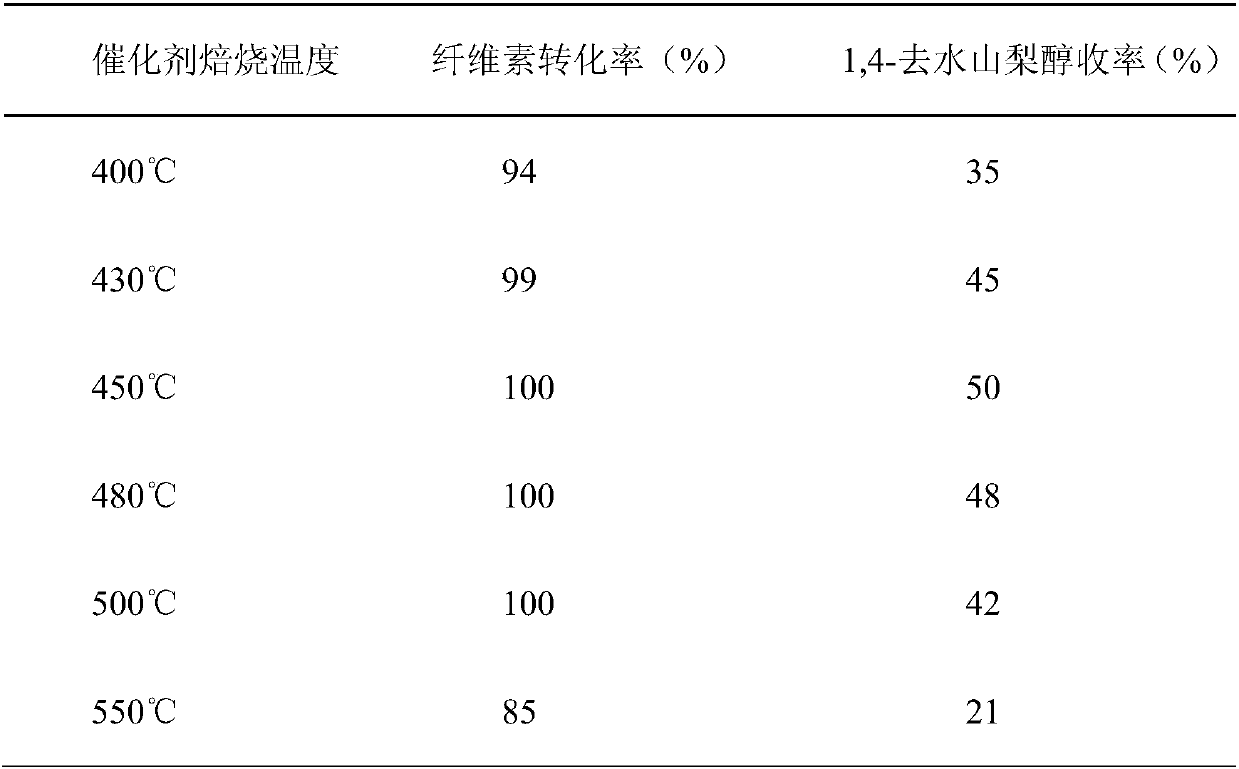

[0022] Example 1: Evaluation of the catalytic performance of niobium phosphate obtained at different calcination temperatures to catalyze the conversion of cellulose into 1,4-sorbitan.

[0023] Add 30ml of water into the reaction kettle as a solvent, add 0.3g of α-cellulose as a raw material, add 0.03g of Ru / C (5wt%, Aladdin), 0.3g of niobium phosphate catalyst, and react at 220°C for 3h under a hydrogen atmosphere of 5MPa. After the reaction was cooled down, the liquid phase product was detected and quantitatively analyzed by high performance liquid chromatography.

[0024] Described niobium phosphate catalyst is prepared by hydrothermal method, and its preparation method comprises the following steps:

[0025] Step 1: Preparation of niobium hydroxide: hydrofluoric acid with a molar ratio of 5:1 and niobium pentoxide heated in water at 100°C for 12 hours to obtain niobium fluoride solution; after cooling, titrate with ammonia water until alkaline to obtain niobium hydroxide p...

Embodiment 2

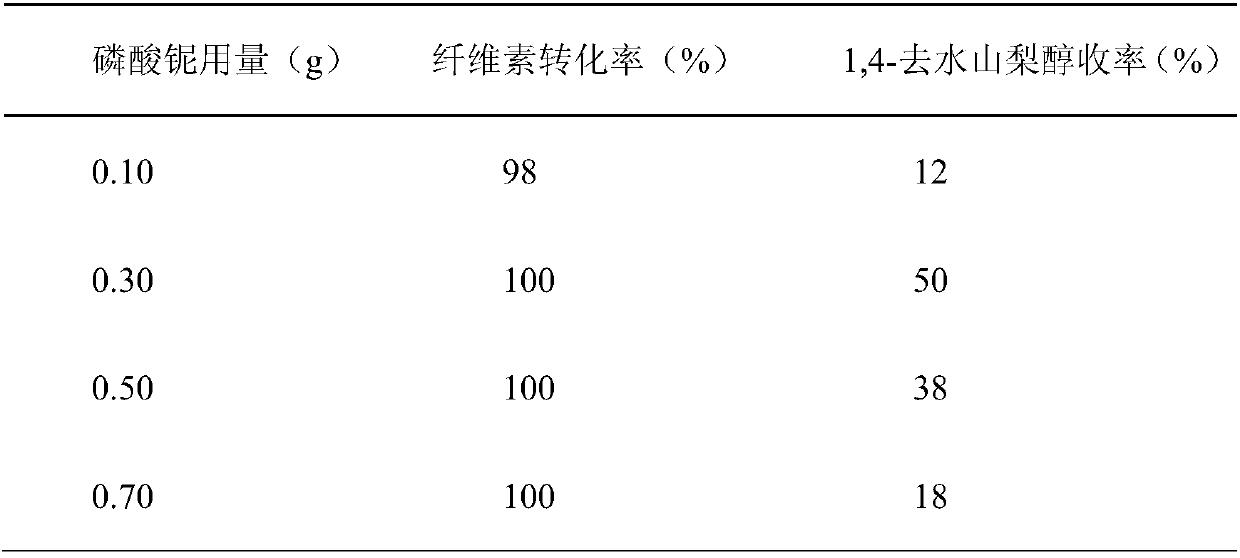

[0031] Embodiment 2: change the catalytic performance evaluation of reacting to the catalyst dosage of niobium phosphate

[0032] The difference between this example and Example 1 is that niobium phosphate (calcined at 450° C.) with better catalytic effect is selected as the catalyst, and the amount of the niobium phosphate catalyst is different.

[0033] Catalytic Performance Evaluation:

[0034] Add 30ml of water as a solvent, 0.3g of α-cellulose as a raw material, 0.03g of Ru / C, and 0.1-0.7g of niobium phosphate as a catalyst in the reaction kettle, and react at 220°C for 3 hours under a 5MPa hydrogen atmosphere. The catalytic effect is shown in Table 2:

[0035] Table 2 Catalytic Performance Evaluation of Different Niobium Phosphate Catalyst Consumption on Reaction

[0036]

Embodiment 3

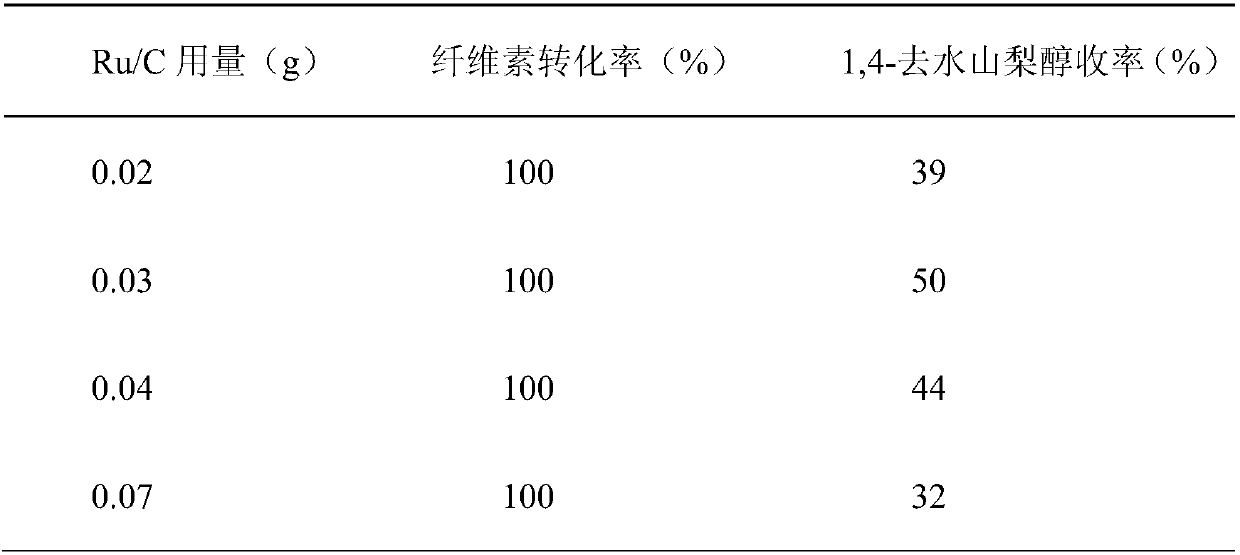

[0037] Embodiment 3: change Ru / C catalyst consumption to the catalytic performance evaluation of reaction

[0038]The difference between this example and Example 1 is that niobium phosphate (calcined at 450° C.) with better catalytic effect is selected as the acid catalyst, but the amount of Ru / C catalyst is different.

[0039] Catalytic Performance Evaluation:

[0040] Add 30ml of water as a solvent, 0.3g of α-cellulose as a raw material, 0.3g of niobium phosphate, and 0.02-0.07g of Ru / C into the reaction kettle, and react at 220°C for 3 hours under a 5MPa hydrogen atmosphere. The catalytic effect is shown in Table 3:

[0041] Table 3 Catalytic performance evaluation of Ru / C catalyst dosage on the conversion of cellulose to 1,4-sorbitol

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com