Preparation and application of organic tin-halogen compound luminescent material

A technology of halogen compounds and luminescent materials, applied in tin organic compounds, luminescent materials, chemical instruments and methods, etc., can solve the problems of high toxicity and high cost of raw materials, achieve high luminescent properties, simple synthesis and preparation methods, and cheap and easy-to-obtain raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of hexamethylenediamine tin bromide, concrete steps are:

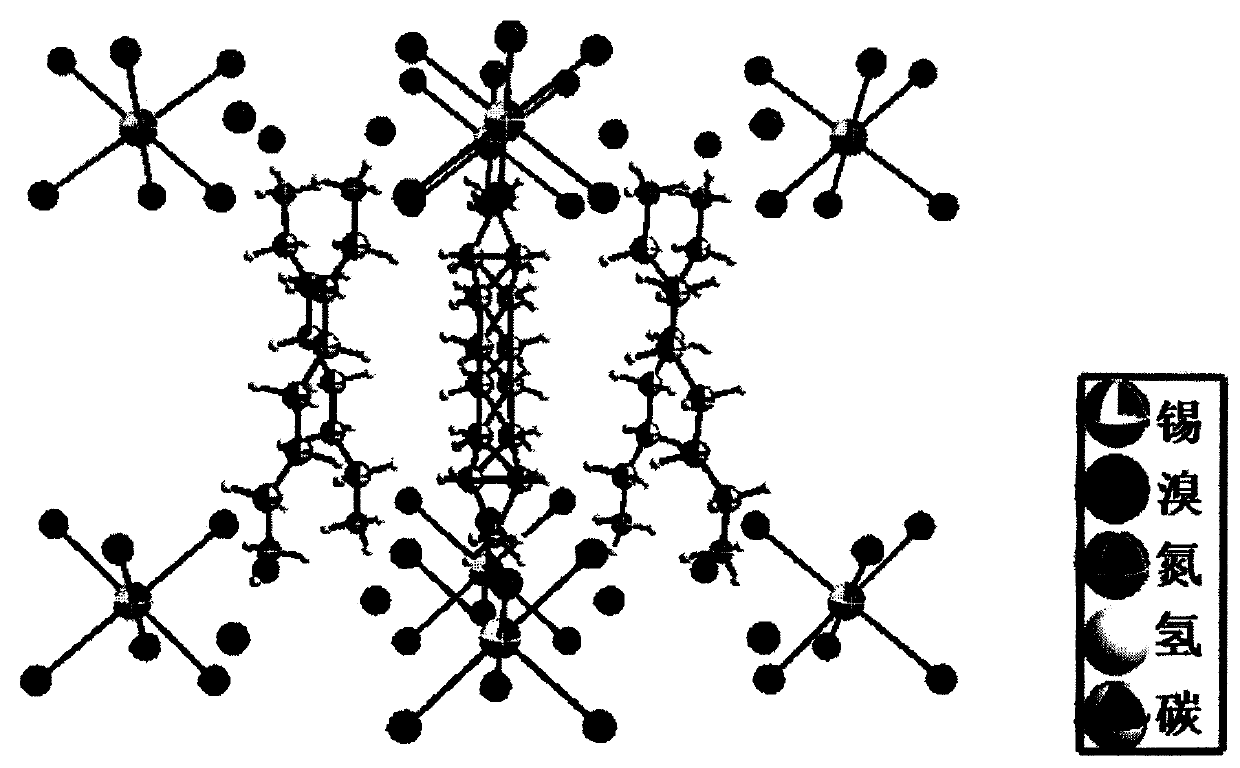

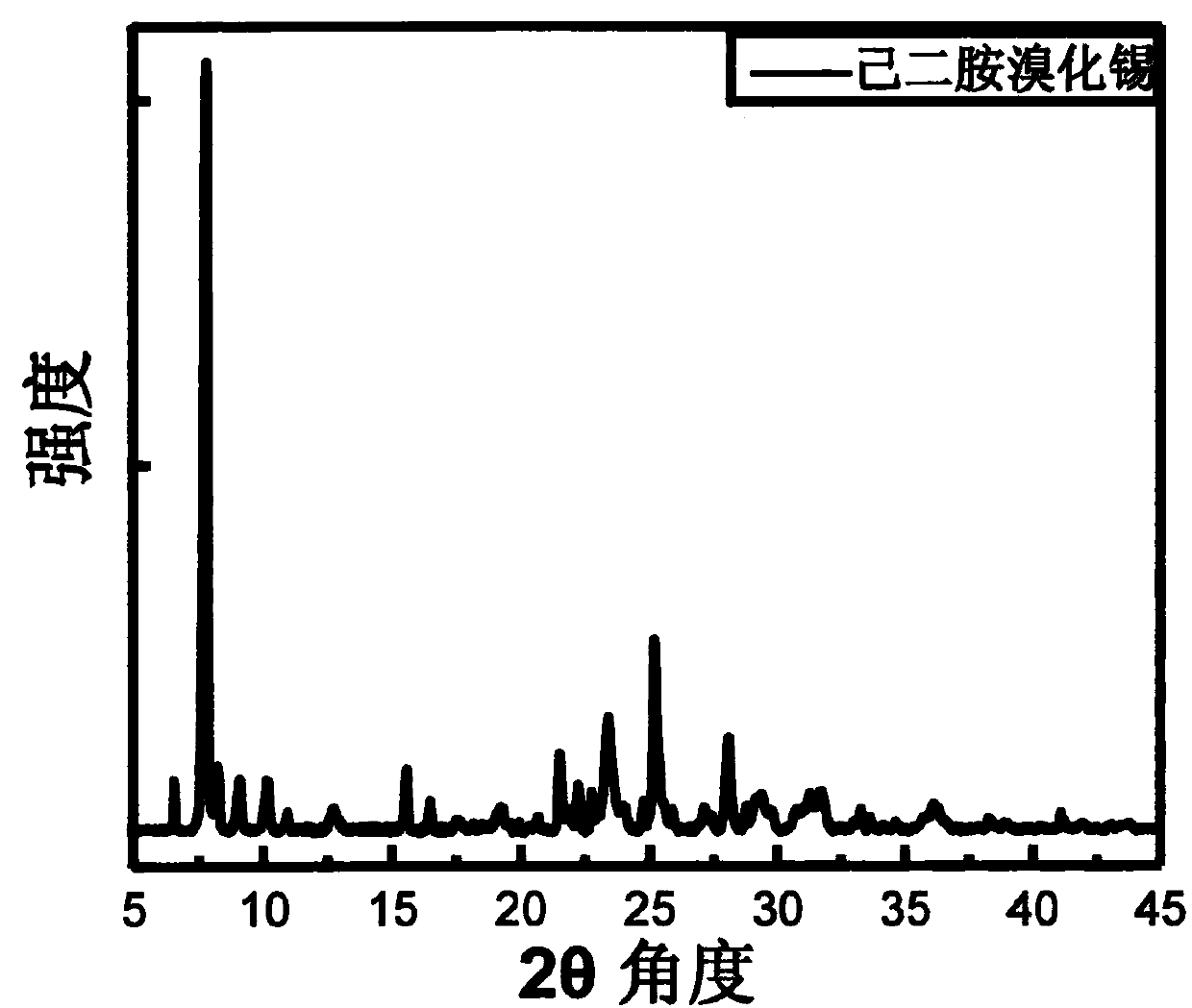

[0036] Weigh 278 mg (1 mmol) of tin dibromide and 834 mg (3 mmol) of hexamethylenediamine bromide into a 20 ml sample bottle, and add 5 ml of DMF to fully dissolve it. The obtained clear and transparent solution was filtered with a 0.22um microporous membrane, 25ml of dichloromethane was added, allowed to stand still and allowed to crystallize and precipitate. After 12 hours, the precipitation was complete, and the supernatant was slowly poured out, and then 25ml of dichloromethane was added to wash the precipitate. After repeated operations twice, the solid was taken out and dried naturally in an anhydrous oxygen environment to obtain a white granular solid hexamethylenediamine bromide Tin, the fluorescence quantum yield is 86% measured by the hyperbolic method, and its crystal structure is as figure 1 As shown, its XRD pattern is as figure 2 Its absorption and emission spectra are sho...

Embodiment 2

[0038] The preparation method of butylamine tin bromide, concrete steps are:

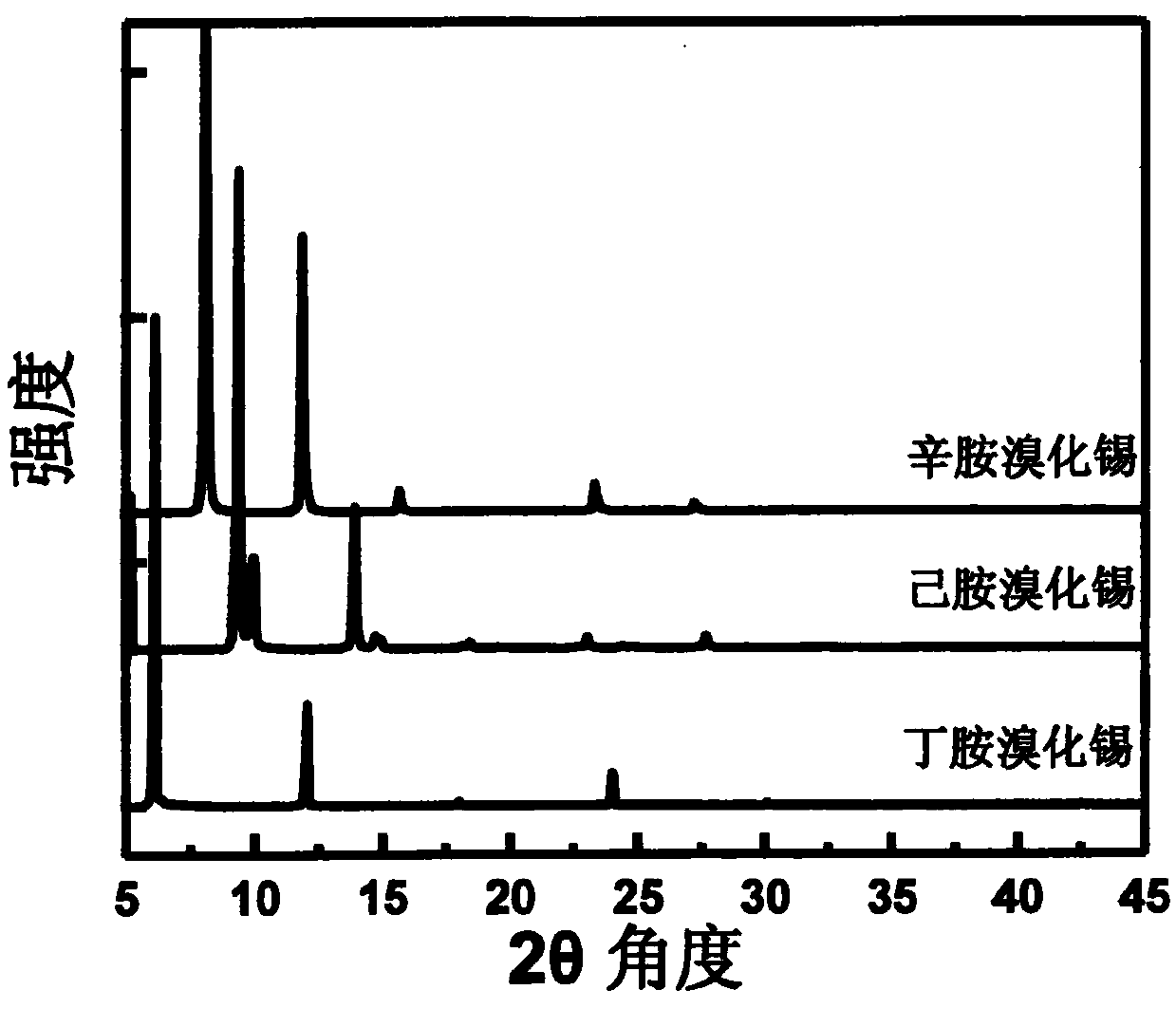

[0039] Weigh 278 mg (1 mmol) of tin dibromide and 924 mg (6 mmol) of octylamine bromide into a 20 ml sample bottle, and add 5 ml of DMF to fully dissolve it. The obtained clear and transparent solution was filtered with a 0.22um microporous membrane, 25ml of dichloromethane was added, allowed to stand still and allowed to crystallize and precipitate. After 12 hours, the precipitation was complete, and the supernatant was slowly poured out, and then 25ml of dichloromethane was added to wash the precipitate. After repeated operations twice, the solid was taken out and dried naturally in an anhydrous oxygen environment to obtain a white flaky solid butylamine bromide Tin, the fluorescence quantum yield measured by the hyperbolic method is 82%, and its XRD pattern is as follows image 3 shown.

Embodiment 3

[0041] The preparation method of hexylamine tin bromide, concrete steps are:

[0042] Weigh 278mg (1mmol) of tin dibromide and 1092mg (6mmol) of octylamine bromide into a 20ml sample bottle, and add 5ml of DMF to fully dissolve it. The obtained clear and transparent solution was filtered with a 0.22um microporous membrane, 25ml of dichloromethane was added, allowed to stand still and allowed to crystallize and precipitate. After 12 hours, the precipitation was complete, and the supernatant was slowly poured out, and then 25ml of dichloromethane was added to wash the precipitate. After repeated operations twice, the solid was taken out and dried naturally in an anhydrous oxygen environment to obtain a white flaky solid hexylamine bromide Tin, the fluorescence quantum yield measured by the hyperbolic method is 62%, and its XRD pattern is as follows image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com