Oil-soluble coal-fired soot remover and preparation method thereof

An oil-soluble, soot-removing agent technology, applied in the direction of fuel additives, fuel, petroleum industry, etc., can solve the problems of large amount of addition, low efficiency of soot-cleaning agent, high cost, etc., to reduce corrosion, reduce transportation and use Cost, effect of reducing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

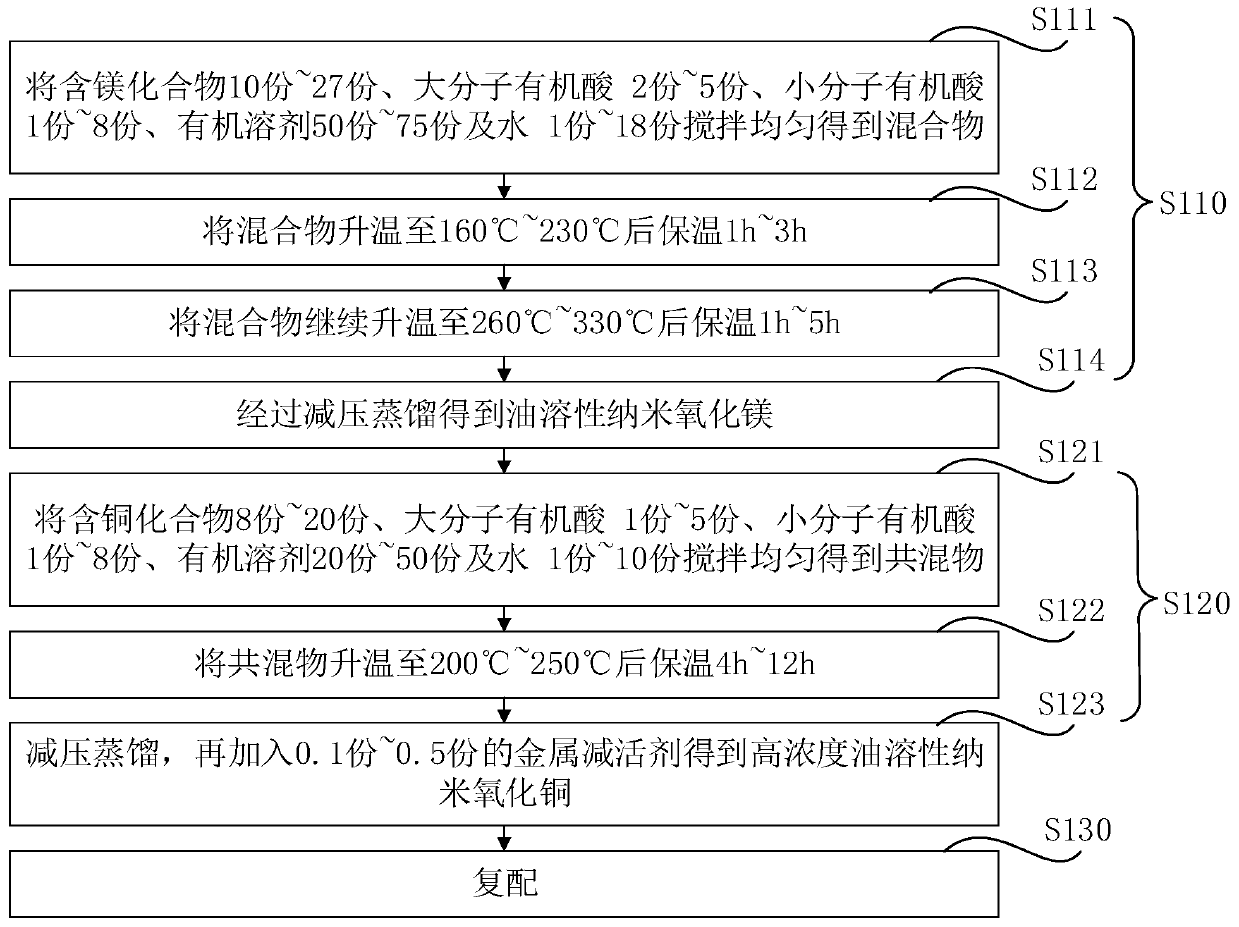

[0074] see further figure 1 , the preparation method of the above-mentioned oil-soluble coal-fired soot remover comprises the following steps:

[0075] S110, preparation of oil-soluble nano-magnesium oxide

[0076] In one of the embodiments, the step of preparing oil-soluble nano magnesium oxide specifically includes:

[0077] S111. Stir 10-27 parts of a magnesium-containing compound, 2-5 parts of a macromolecular organic acid, 1-8 parts of a small-molecular organic acid, 50-75 parts of an organic solvent, and 1-18 parts of water to obtain a mixture .

[0078] S112. The temperature of the mixture is raised to 160° C. to 230° C., and the temperature is maintained for 1 h to 3 h.

[0079] S113. Continue to raise the temperature of the mixture to 260° C. to 330° C., and then keep it warm for 1 hour to 5 hours.

[0080] S114, obtaining high-concentration oil-soluble nano-magnesium oxide through vacuum distillation.

[0081] In one embodiment, the temperature during vacuum dis...

Embodiment 1

[0095] In parts by mass, 40 parts of oil-soluble nano-magnesium oxide, 25 parts of oil-soluble nano-copper oxide, 3 parts of stearylamide, 13 parts of propanol, 1 part of propyl laurate and 8 parts of lemon Zinc acid is added to the preparation kettle and heated to 45°C, stirred at a stirring speed of 400r / min for 0.5h until uniformly mixed to obtain an oil-soluble coal-fired soot remover.

[0096]Among them, the preparation method of oil-soluble nano-magnesium oxide is as follows: in parts by mass, 20 parts of magnesium oxide, 2 parts of myristic acid, 6 parts of acetic acid, 55 parts of olefin oligomers and 18 parts of water are stirred evenly, and the temperature is raised to 200 ° C. Then heat-preserve and react for 3 hours; then continue to heat up to 330° C., heat-retain and react for 2 hours, and concentrate to obtain the oil-soluble nano-magnesium oxide.

[0097] Wherein, the preparation method of oil-soluble nano-copper oxide is: in parts by mass, 12 parts of copper h...

Embodiment 2

[0099] In terms of parts by mass, 45 parts of oil-soluble nano-magnesia, 15 parts of oil-soluble nano-copper oxide, 1 part of polyacrylic acid, 5 parts of n-butanol, 1 part of urea and 8 parts of ferrocene were added Heat it in the preparation tank to 50°C, stir at a stirring rate of 300r / min for 0.5h until uniformly mixed to obtain an oil-soluble coal-fired soot remover.

[0100] Wherein, the preparation method of oil-soluble nano-magnesium oxide is as follows: in parts by mass, 25 parts of magnesium hydroxide, 2 parts of dodecanoic acid, 6 parts of propionic acid, 60 parts of heavy aromatics and 12 parts of water are stirred evenly, and the temperature is raised to After heating at 230° C. for 1 hour; then continue to heat up to 280° C., then hold it for 4 hours and concentrate to obtain the oil-soluble nano-magnesium oxide.

[0101] Wherein, the preparation method of oil-soluble nano-copper oxide is as follows: in parts by mass, 16 parts of copper oxide, 3 parts of naphthen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com