ABT-199 nano-emulsion dispersing agent and preparation method thereof

A technology of ABT-199 and ABT-1994%, applied in the preparation of ABT-199 nano-emulsion dispersant, in the field of ABT-199 nano-emulsion dispersant, it can solve the problem of poor water solubility, low bioavailability, strong toxic and side effects of compounds, etc. problems, to achieve the effects of good stability, simple preparation method, high encapsulation rate and drug loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

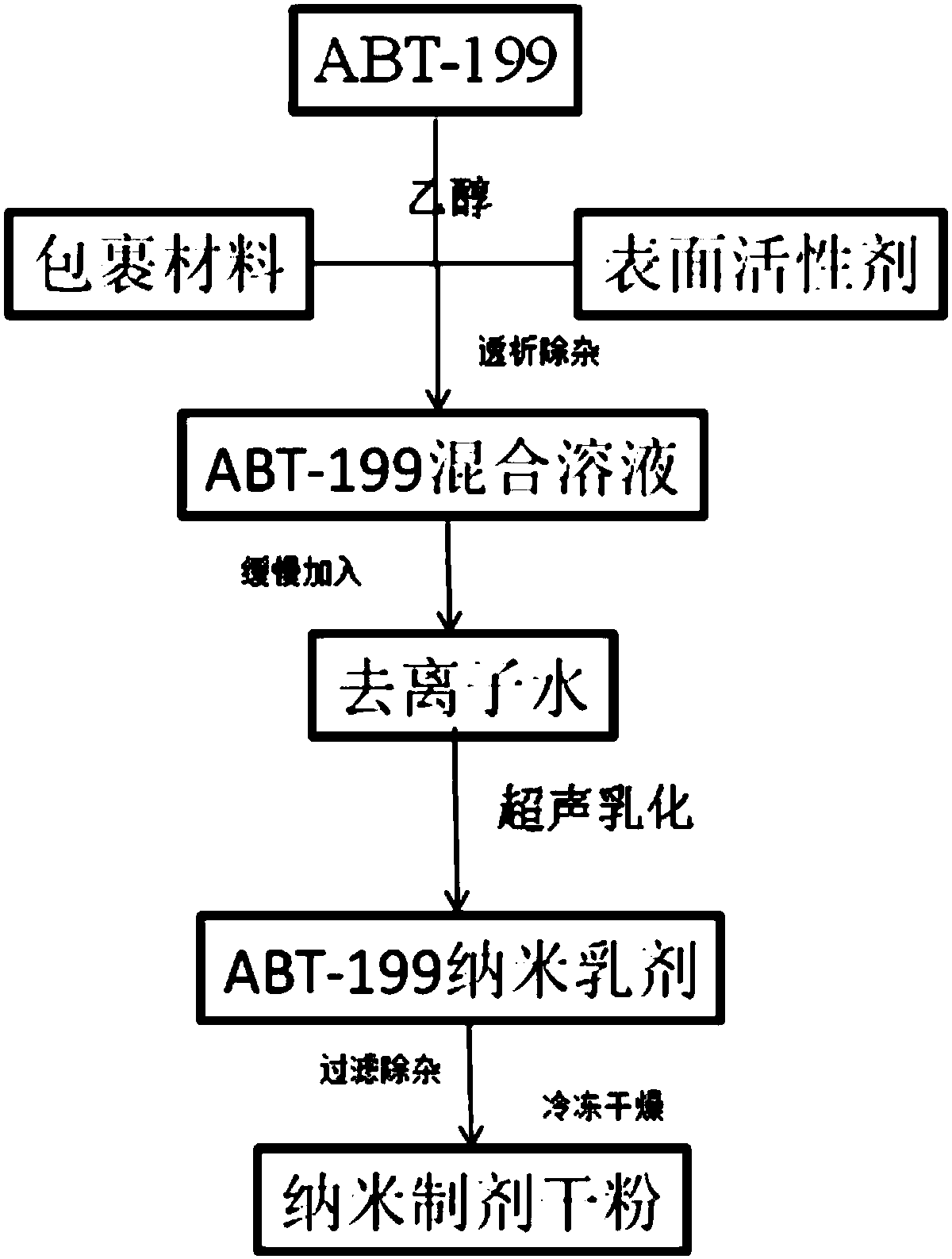

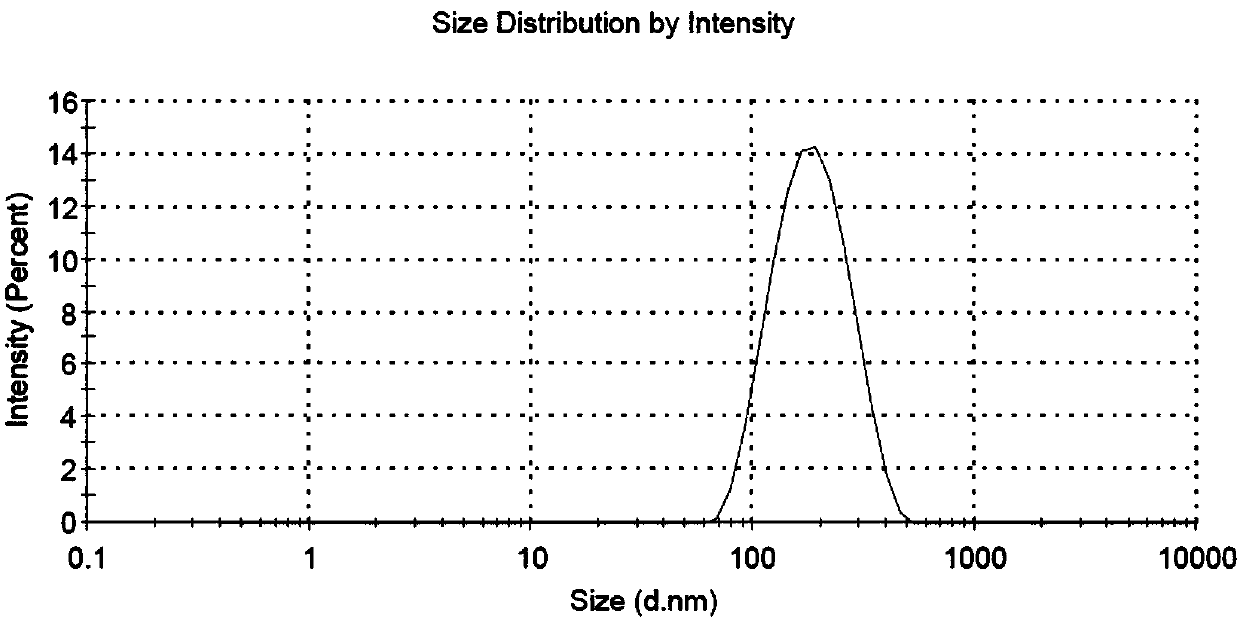

[0035] A preparation method of ABT-199 nanoemulsion dispersant, such as figure 1 As shown, the specific steps are as follows:

[0036] Step 1. Weigh raw materials: weigh 4% to 8% of ABT-199, 28% to 40% of wrapping material, 20% to 34% of surfactant, and 29% to 38% of lyoprotectant according to mass percentage;

[0037] Step 2. Dissolve ABT-199 in ethanol, the volume ratio of ABT-199 and ethanol is 1:20, then mix the wrapping material and surfactant together into the ethanol solution, after fully dissolved, filter to remove impurities, filter Use a fat-soluble filter membrane with a pore size of 0.22 μm to obtain a mixed solution;

[0038] Step 3. Slowly add the mixed solution obtained in step 2 into deionized water at a rate of 10-20ml / min. The volume ratio of the mixed solution to deionized water is 1:10. Stir at a rate of 300-500rpm , followed by ultrasonic treatment, the ultrasonic treatment uses a probe-type ultrasonic breaker, the power is 400-800W, the ultrasonic treat...

Embodiment 1

[0043] A preparation method of ABT-199 nanoemulsion dispersant, specifically implemented according to the following steps:

[0044] Step 1. Weigh raw materials: weigh 4% of ABT-199, 32% of wrapping material, 28% of surfactant, and 36% of lyoprotectant by mass percentage;

[0045] Step 2. Dissolve 4g of ABT-199 in 80ml of ethanol. Use soybean lecithin as the wrapping material and Tween-80 as the surfactant. Mix 32g of soybean lecithin and 28g of Tween 80 into the ethanol solution. After fully dissolving, Impurities are removed by filtration, and the filtration is carried out with a fat-soluble filter membrane with a pore size of 0.22 μm to obtain a mixed solution;

[0046] Step 3. Slowly add the mixed solution obtained in step 2 into 800 deionized water, control the adding speed to 10ml / min, stir, and the stirring speed is 300rpm, and then carry out ultrasonic treatment. The ultrasonic treatment utilizes a probe type ultrasonic breaker with a power of 400W, each cycle of ultra...

Embodiment 2

[0052] A preparation method of ABT-199 nanoemulsion dispersant, specifically implemented according to the following steps:

[0053] Step 1. Weigh raw materials: weigh 5% of ABT-199, 30% of wrapping material, 29% of surfactant, and 36% of lyoprotectant by mass percentage;

[0054] Step 2. Dissolve 5g of ABT-199 in 100ml of ethanol, use lecithin as the wrapping material, and use poloxamer 188 as the surfactant, mix 30g of lecithin and 29g of poloxamer 188 into the ethanol solution, wait until fully After dissolving, filter to remove impurities, and filter using a fat-soluble filter membrane with a pore size of 0.22 μm to obtain a mixed solution;

[0055] Step 3. Slowly add the mixed solution obtained in step 2 into 1000 deionized water, control the adding speed to 12ml / min, stir at a stirring speed of 400rpm, and then perform ultrasonic treatment. The ultrasonic treatment utilizes a probe type ultrasonic breaker with a power of 600W, each cycle of ultrasonic treatment time is 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com