Anti-ultraviolet high-barrier transparent packaging film and production method thereof

A transparent packaging and high-barrier technology, applied in packaging, wrapping paper, household packaging, etc., can solve the problems of reducing barrier properties, package breakage and delamination of packaged products, and achieve low surface friction coefficient, high food safety, The effect of improving mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

[0043] The production method of described anti-ultraviolet high barrier transparent packaging film comprises the following steps:

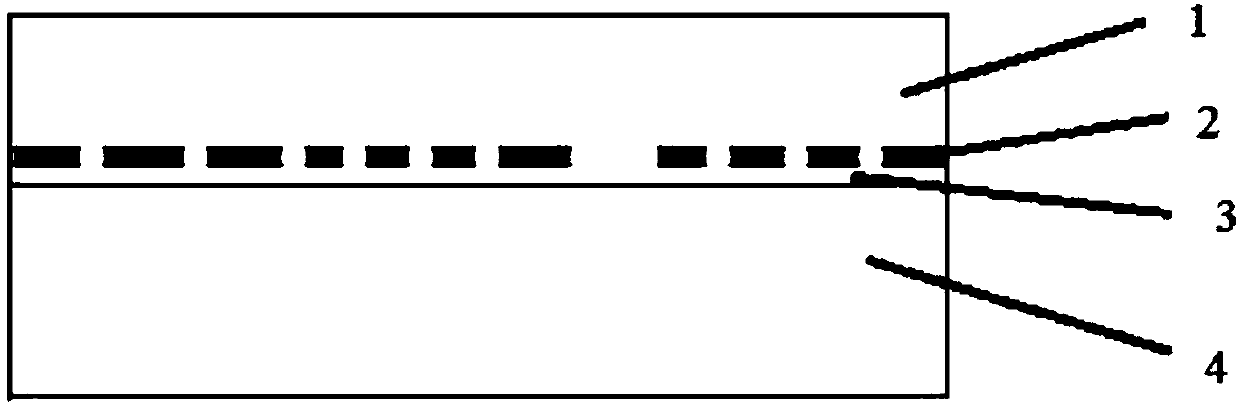

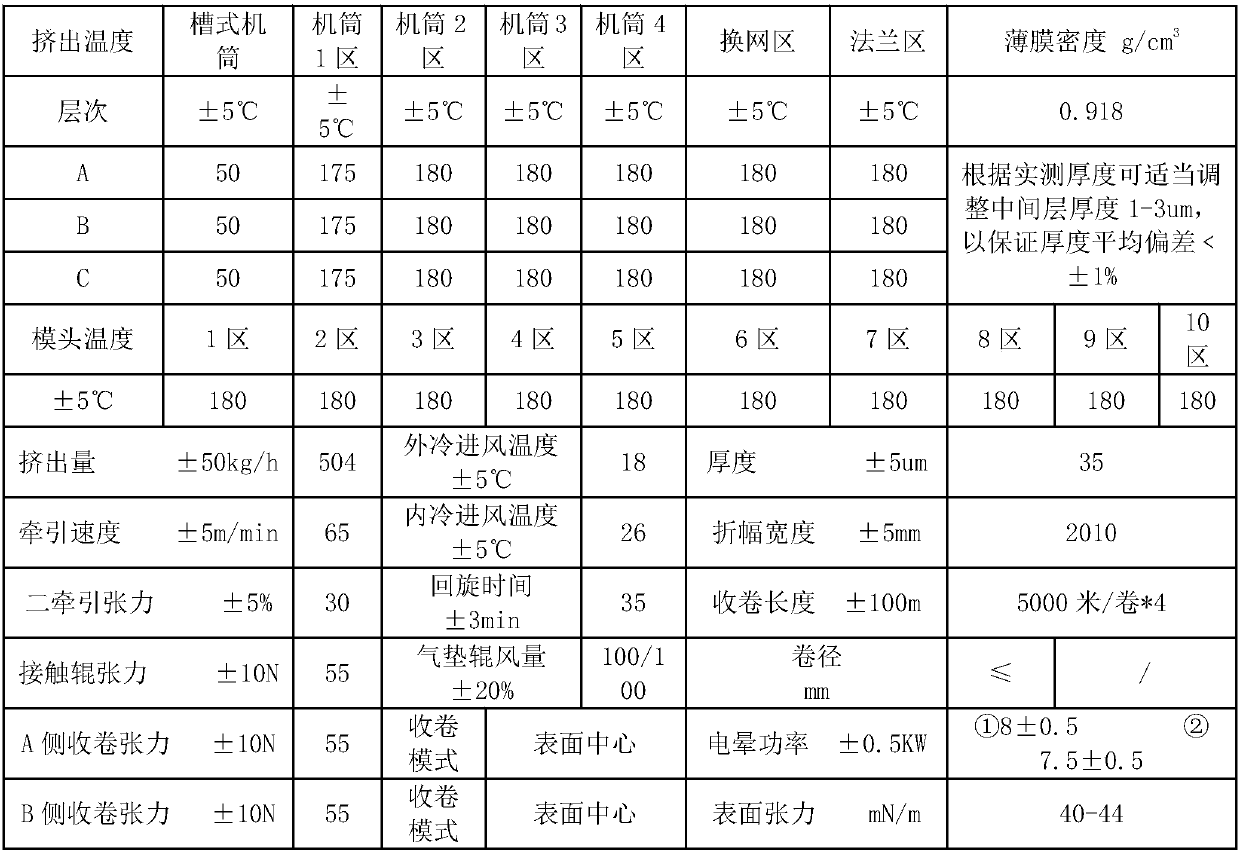

[0044] Step 1, preparation of the co-extruded PE film layer: the materials contained in the outer layer, the middle layer and the printing layer are respectively added to the co-extrusion blown film machine according to the above component requirements and obtained by three-layer co-extrusion Described co-extrusion PE film layer, then form ink layer after described printing layer surface printing; The processing parameter of described co-extrusion PE film layer is as shown in table 1 below:

[0045] Table 1

[0046]

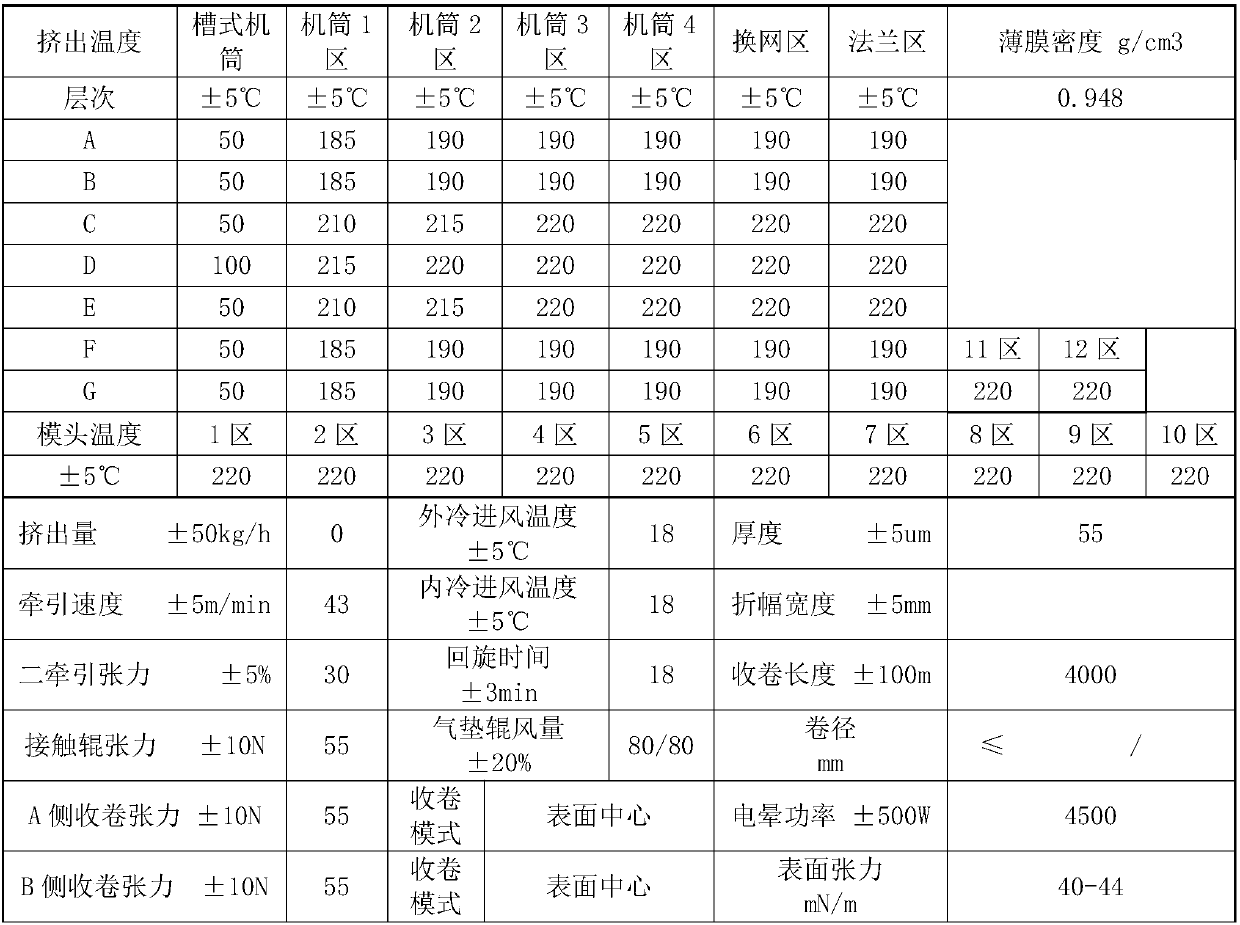

[0047] Preparation of co-extrusion high barrier film layer: the materials contained in the A composite layer, B outer layer, C adhesive layer, D middle layer, E adhesive layer, F outer layer and G heat seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com