Preparation method and application of fritillaria pallidiflora total polysaccharide

A technology of ibeimus and total polysaccharide is applied in the field of preparation of ibeimus total polysaccharide, can solve problems such as being unable to completely and effectively prevent body damage, safety and the like, and achieves the improvement of human immune performance, extensive biological activity and high yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

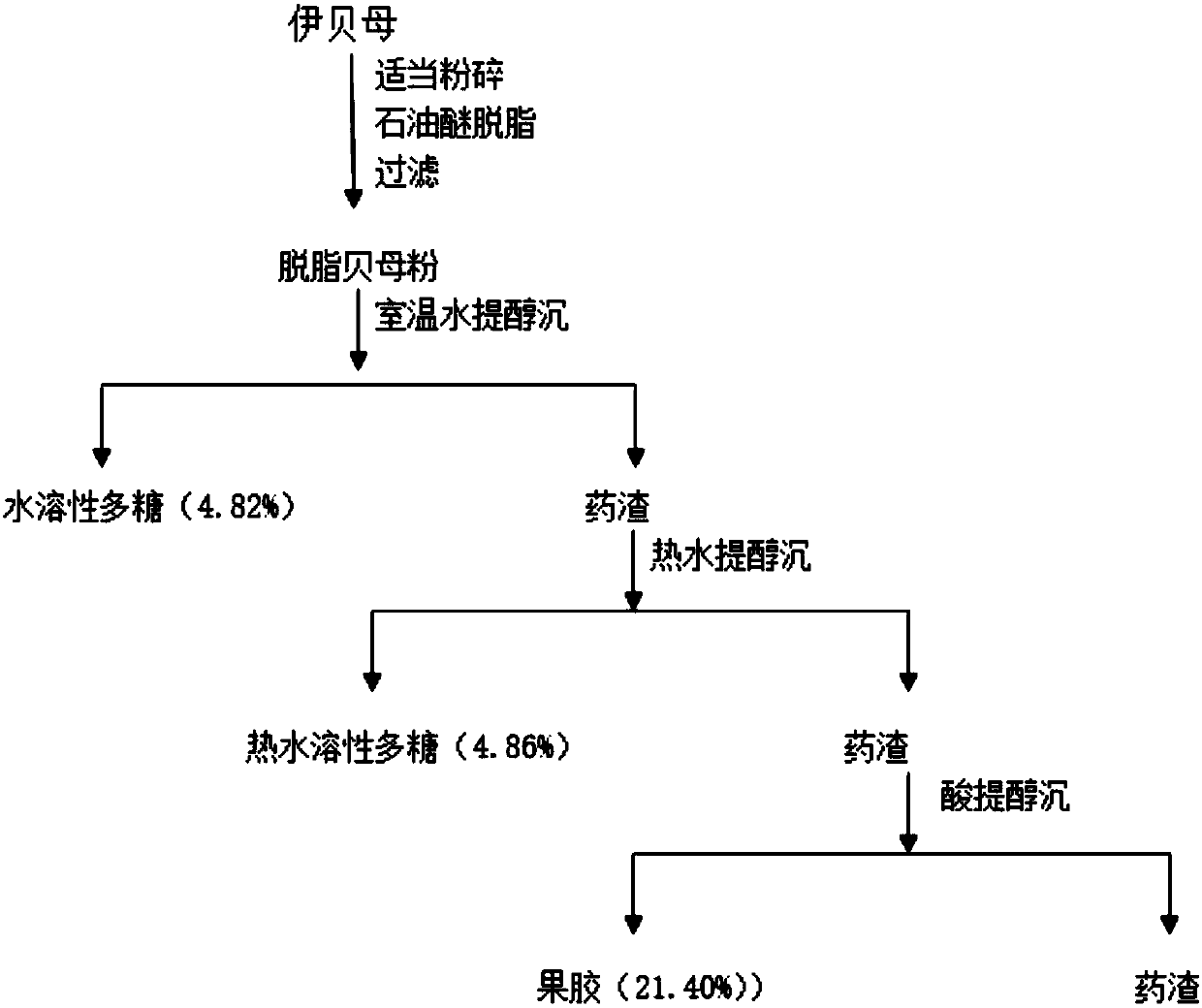

[0039] a. The collected Iberia bulbs are dried naturally in the shade and then mechanically pulverized for 60 seconds, passed through a 60-mesh sieve, separated from impurities, and obtained powder;

[0040] b. Add petroleum ether to the powder obtained in step a according to the weight ratio of material to liquid at 1:5, stir at room temperature for 1 hour, repeat extraction 3 times until no oil is extracted, filter, and naturally air-dry until no petroleum ether solvent remains So far, the degreased Igbe mother powder is obtained;

[0041] c, prepare three kinds of polysaccharide concentrates respectively:

[0042] According to the weight ratio of 1:30, add water to the degreased mother-of-pearl powder obtained in step b, stir and extract twice at room temperature, the extraction time is 2 hours, filter, combine the extracts, 10000rpm, temperature 4°C, centrifuge for 10min, concentrate, Obtain the polysaccharide concentrate for subsequent use;

[0043] Collect the filtered...

Embodiment 2

[0048] a. The collected Iberia bulbs are mechanically crushed after being dried naturally in a cool place, and the crushing time is 100 seconds, passed through a 60-mesh sieve, and the sundries are separated to obtain a powder;

[0049] b. Add petroleum ether to the powder obtained in step a according to the weight ratio of material to liquid at 1:5, stir at room temperature for 2 hours, repeat extraction 4 times until no oil is extracted, filter, and air-dry naturally until no petroleum ether solvent remains So far, the degreased Igbe mother powder is obtained;

[0050] c, prepare three kinds of polysaccharide concentrates respectively:

[0051] According to the weight ratio of 1:30, add water to the degreased mother-of-pearl powder obtained in step b, stir and extract twice at room temperature, the extraction time is 2 hours, filter, combine the extracts, 10000rpm, temperature 4°C, centrifuge for 10min, concentrate, Obtain the polysaccharide concentrate for subsequent use; ...

Embodiment 3

[0057] a. The collected Iberia bulbs are mechanically crushed after being dried naturally in the shade, and the crushing time is 120 seconds. Pass through a 60-mesh sieve to separate impurities and obtain a powder;

[0058] b. Add petroleum ether to the powder obtained in step a according to the weight ratio of material to liquid at 1:5, stir at room temperature for 1 hour, repeat extraction 3 times until no oil is extracted, filter, and naturally air-dry until no petroleum ether solvent remains So far, the degreased Igbe mother powder is obtained;

[0059] c, prepare three kinds of polysaccharide concentrates respectively:

[0060] According to the weight ratio of 1:30, add water to the degreased mother-of-pearl powder obtained in step b, stir and extract twice at room temperature, the extraction time is 2 hours, filter, combine the extracts, 10000rpm, temperature 4°C, centrifuge for 10min, concentrate, Obtain the polysaccharide concentrate for subsequent use;

[0061] Coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com