A Wire Bonding Method Based on Rapid Local Electrodeposition

A wire bonding and electrodeposition technology, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of inability to interconnect wire materials and pads, unreliable wire bonding technology, etc., and achieve fast bonding speed. , Reliable wire bonding, no thermal damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

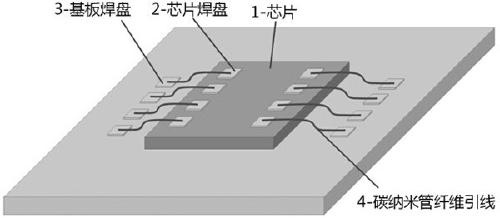

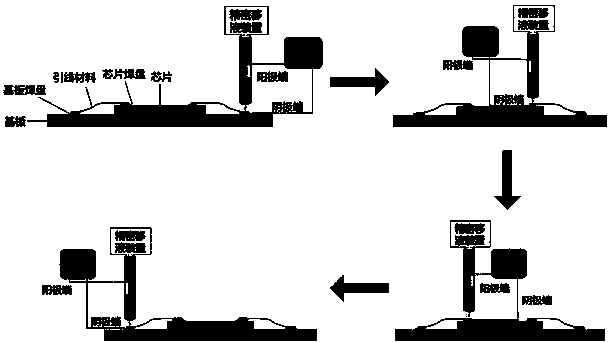

[0027] Specific implementation mode 1: This implementation mode records a wire bonding method based on rapid local electrodeposition. Using the method of local electrodeposition, the new wire material and pad surface that cannot be used in traditional wire bonding technology are realized. Connection, the specific steps of the method are as follows:

[0028] Step 1: Select the wire material to be bonded;

[0029] Step 2: modifying the surface of the lead material selected in step 1, so that the local electrodeposition solution can wet the surface well;

[0030] Step 3: According to the position requirements, place the lead material after surface modification on the surface of the pad through the micro-nano operation platform, ensure that the two ends of the lead are located at the center of the surface of the pad, and ensure that the two ends of the lead are in good contact with the surface of the pad. s contact;

[0031] Step 4: According to the size of the pad, select the d...

specific Embodiment approach 2

[0034] Specific embodiment 2: A wire bonding method based on rapid local electrodeposition according to specific embodiment 1, wherein the lead material is a carbon-based lead material, a carbon-surface-enhanced metal-based lead material, or a carbon-composite metal-based lead Material,

[0035] The carbon-based lead material is carbon fiber, carbon nanotube fiber or graphene sheet; the carbon surface-enhanced metal-based lead material is a surface-oriented growth carbon nanotube metal lead, a surface-oriented growth graphene metal lead or a surface coating Graphene-coated metal foil; the carbon composite metal-based lead material is a carbon nanotube composite metal lead or a graphene composite metal lead; the metal is one of copper, nickel, gold or aluminum.

specific Embodiment approach 3

[0036] Specific embodiment three: a wire bonding method based on rapid local electrodeposition described in specific embodiment one, in step two, the surface modification includes surfactant adsorption modification, laser and plasma etching modification After modification, the electrodeposition solution can be well spread on the lead material, and the surface wetting angle of the lead material is less than 10°.

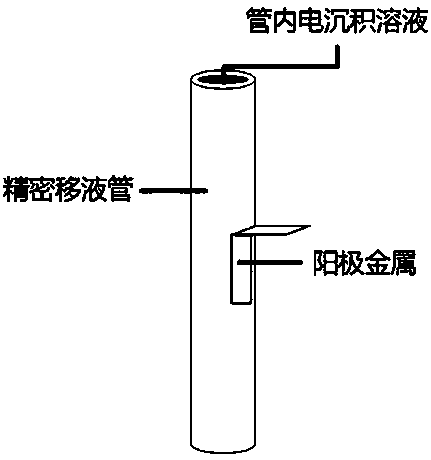

[0037] Embodiment 4: A wire bonding method based on rapid local electrodeposition described in Embodiment 1, step 5 is specifically: the electrodeposition solution is dripped on the micro-nano operating platform through a precision pipette Ensure that the pipette tip is not below the electrodeposition solution liquid level on the surface of the pad, and the electrodeposition solution dripped from the pipette should completely cover the junction of the pad and lead wire, and at the same time ensure that the electrodeposition solution The deposition solution area should...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com