Nuclear power plant containment concrete

A nuclear power plant containment and concrete technology, applied in nuclear power generation, nuclear engineering, climate sustainability, etc., can solve problems such as poor impact resistance and high temperature resistance, polluted environment, and large capacity of ordinary containment concrete, etc., to achieve energy saving resources, reduce the void ratio, and enhance the effect of radiation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

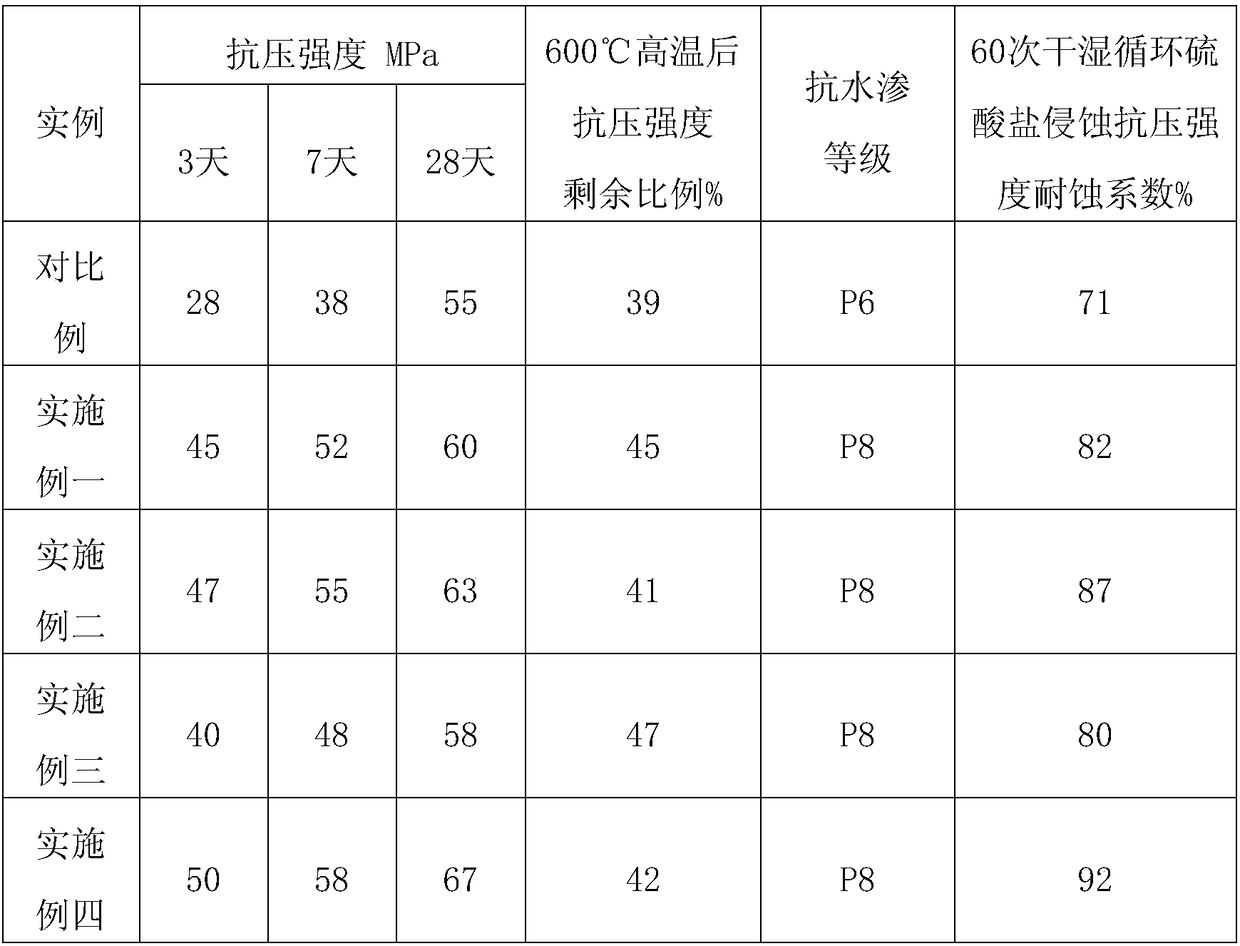

Embodiment 1

[0032] The containment concrete of a nuclear power plant is composed of the following parts by mass: 200 parts of PII 42.5 cement, 120 parts of slag, 50 parts of metakaolin, 100 parts of boron glass sand, 700 parts of nickel slag, 800 parts of barite, 200 parts of limonite, and ceramsite 200 parts, 40 parts of lead fiber, 160 parts of water, 4 parts of polycarboxylate superplasticizer, 5 parts of early strength agent. After the concrete was cured for 28 days, a layer of precipitated BaSO4 with polyimide as the binder was coated on the inner surface of the concrete. 4 Organic solvent radiation protection coating.

Embodiment 2

[0034] The containment concrete of a nuclear power plant is composed of the following parts by mass: 140 parts of PII 52.5 cement, 60 parts of slag, 100 parts of metakaolin, 50 parts of boron glass sand, 750 parts of nickel slag, 700 parts of barite, 400 parts of limonite, ceramsite 100 parts, 50 parts of lead fiber, 130 parts of water, 6 parts of polycarboxylate superplasticizer, 4.5 parts of early strength agent. After 28 days of concrete curing, a layer of precipitated BaSO4 with polyoxadiazole as a binder was coated on the inner surface of the concrete. 4 Organic solvent radiation protection coating.

Embodiment 3

[0036] The containment concrete of a nuclear power plant is composed of the following parts by mass: 130 parts of PII 42.5 cement, 100 parts of slag, 80 parts of metakaolin, 150 parts of boron glass sand, 600 parts of nickel slag, 600 parts of barite, 300 parts of limonite, ceramsite 300 parts, 20 parts of lead fiber, 140 parts of water, 4.5 parts of polycarboxylate superplasticizer, 6 parts of early strength agent. After 28 days of concrete curing, a layer of precipitated BaSO4 with polyoxadiazole as a binder was coated on the inner surface of the concrete. 4 Organic solvent radiation protection coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com