Method of producing pig feed with kitchen waste

A technology of food waste and pig feed, applied in animal feed, animal feed, application, etc., can solve the problems of easy corruption and deterioration of feed, accumulation of toxins, etc., to improve immunity and anti-stress ability, reduce morbidity, improve The effect of immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

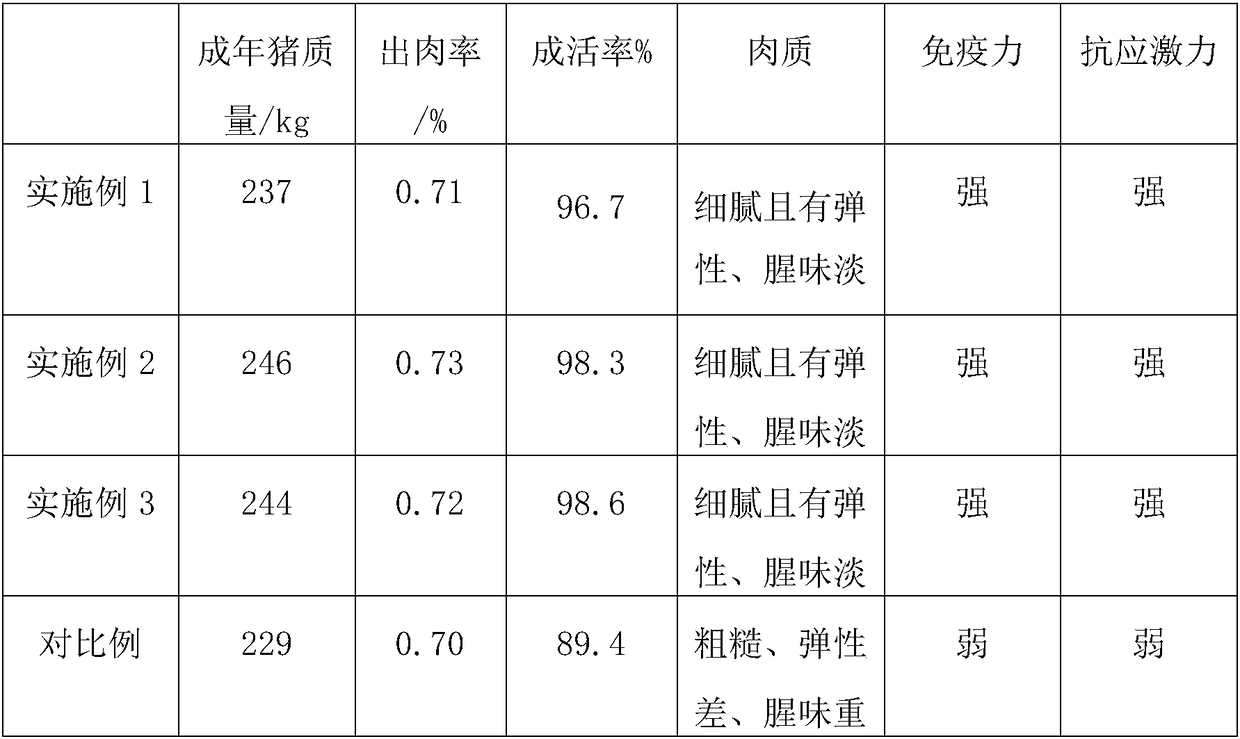

Examples

Embodiment 1

[0018] Step 1: Separating the paper, chopsticks, toothpicks and plastics from the food waste, filtering, crushing and drying, so that the particle size is 30 mesh and the organic dry matter content is ≧50%;

[0019] Step 2: Add 15% soybean flour and 20% rice bran to the pretreated kitchen waste in Step 1, stir evenly, and sterilize with high pressure steam at 121°C for 20 minutes to obtain a fermentation substrate;

[0020] Step 3: At 28°C, inoculate 2 parts of Bifidobacterium, 6 parts of Lactobacillus, 3 parts of Bifidobacterium and 5 parts of yeast in a liquid medium with a pH of 6.2, and inoculate 10 m 3 The flow rate of / h is passed into sterile air, and after 2 days of expansion, it is concentrated and purified to obtain a composite bacterial agent. Under the nitrogen-filled condition of 28°C, after mixing 10% of the composite bacterial agent in the fermentation substrate of step 2, Every 3h, stir 20min with the speed of 60r / min, after fermenting 20h, make crude feed;

...

Embodiment 2

[0023] The operation is the same as in Example 1, the particle fineness in step 1 is 45 mesh; the dosage of soybean flour and rice bran in step 2 is 17.5%, 25% respectively, and sterilized for 25 minutes; 4 parts, 8 parts, 5 parts and 7 parts in turn, the temperature of the preparation process is 32°C, the pH is 6.5, and the flow rate is 12.5m 3 / h, the number of days of expansion is 3 days, the dosage is 12.5%, the fermentation temperature is 32°C, the time is 28h, the intermittent stirring process: every 3h, stir at a rate of 70r / min for 25min, the Chinese herbal medicine in step 4 The parts by weight of each antibiotic component are 25 parts, 14 parts, 21 parts, 17 parts and 0.04 parts in sequence, and the dosages of calcium dihydrogen phosphate and Chinese herbal antibiotics are 0.8% and 0.15% respectively.

Embodiment 3

[0025] The operation is the same as in Example 1, the particle fineness in step 1 is 60 mesh; the dosage of soybean flour and rice bran in step 2 is 20%, 30% respectively, and sterilized for 30min; 6 parts, 10 parts, 7 parts and 9 parts in turn, the temperature of the preparation process is 36°C, the pH is 6.8, and the flow rate is 15m 3 / h, the number of days of expansion is 4 days, the dosage is 15%, the fermentation temperature is 36°C, the time is 36h, the intermittent stirring process: every 5h, stir at a speed of 80r / min for 30min, the Chinese herbal medicine in step 4 The parts by weight of the antibiotic components are 30 parts, 16 parts, 24 parts, 19 parts and 0.05 parts in sequence, and the dosages of calcium dihydrogen phosphate and Chinese herbal medicine antibiotics are 1.0% and 0.2% respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com