Preparation method of high-selectivity methane halogenation oxidation catalyst

A methane halide oxidation, high selectivity technology, applied in the direction of physical/chemical process catalysts, preparation of halogenated hydrocarbons, chemical instruments and methods, etc., can solve the problems of low yield of methyl halides, reduction of selectivity of methyl halides, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

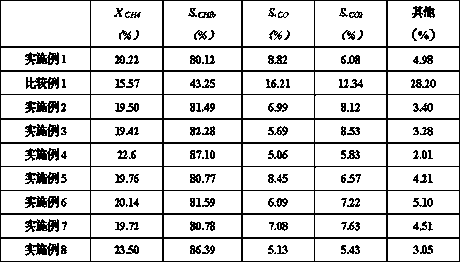

Examples

Embodiment 1

[0028] Preparation of modified alumina: using equal volume impregnation method on alumina (commercially available, the properties are as follows: specific surface 335m 2 / g, pore volume is 0.86ml / g) impregnated with sucrose aqueous solution, the mass concentration of sucrose aqueous solution is 5%, the pH value is 2, the aging temperature is 80℃, the aging time is 2h, the drying temperature after aging is 150℃, the drying time 24h, roasting at 300°C for 3 hours;

[0029] Preparation of zinc-loaded alumina: impregnating zinc nitrate solution on the modified alumina by equal volume impregnation, drying and roasting after impregnation, the drying time is 2 hours, and the drying temperature is 130°C; the roasting time is 4 hours, the temperature 400°C, the zinc-loaded alumina is spherical, and the equivalent diameter of the zinc-loaded alumina is 2 mm;

[0030] Prepare aluminum hydroxide slurry by hydrolysis of aluminum isopropoxide: mix water and aluminum isopropoxide at a molar...

Embodiment 2

[0035] Preparation of modified alumina: using equal volume impregnation method on alumina (commercially available, the properties are as follows: specific surface 335m 2 / g, pore volume is 0.86ml / g), dipped in glucose aqueous solution, the weight concentration of glucose aqueous solution is 20%, the preferred pH value is 3, the aging temperature is 60°C, the aging time is 5h, and the drying temperature after aging is 100°C for 8h. , roasting at 450°C for 3 hours;

[0036] Preparation of zinc-loaded alumina: impregnate the modified alumina with a zinc sulfate solution using an equal-volume impregnation method, dry and roast after impregnation, the drying time is 3 hours, and the drying temperature is 120 ° C; the roasting time is 5 hours, the temperature is 450°C, the zinc-loaded alumina is spherical, and the equivalent diameter of the zinc-loaded alumina is 2mm;

[0037] Prepare aluminum hydroxide slurry by hydrolysis of aluminum isopropoxide: mix water and aluminum isopropox...

Embodiment 3

[0042] Preparation of modified alumina: using equal volume impregnation method on alumina (commercially available, the properties are as follows: specific surface 335m 2 / g, the pore volume is 0.86ml / g), the fructose aqueous solution is impregnated, the weight concentration of the fructose aqueous solution is 10%, the pH value is 1, the aging temperature is 70°C, the aging time is 3.5h, and the drying temperature after aging is 110°C Dry for 15h. Roasting at 380°C for 4 hours;

[0043]Preparation of zinc-loaded alumina: impregnating zinc bromide solution on the modified alumina by an equal volume impregnation method, drying and roasting after impregnation, the drying time is 4 hours, and the drying temperature is 100 ° C; the roasting time is 4 hours, The temperature is 500°C, the zinc-loaded alumina is spherical, and the equivalent diameter of the zinc-loaded alumina is 3mm;

[0044] Prepare aluminum hydroxide slurry by hydrolysis of aluminum isopropoxide: mix water and alu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com