Nanometer multi-layer piston ring coating and preparation method and application thereof

A nano-multi-layer, piston ring technology, applied in the coating, metal material coating process, superimposed layer plating, etc., can solve the problems of high stress, restricted application, low bonding force of CrCN coating, etc., and achieve high hardness , low cost, high binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Further, the preparation method includes: placing the base material of the piston ring in the vacuum chamber of the coating equipment, and sequentially depositing a metal Cr transition layer and a CrCN / Cr nanometer multilayer on the base material of the piston ring by using multi-arc ion plating technology coating, until the formation of the nano-multilayer piston ring coating.

[0043] In some embodiments, the process conditions adopted by the multi-arc ion plating technology include: a Cr target, a target current of 50A to 100A, a bias voltage of -20A to -100A, a temperature of 350°C to 450°C, and working gases including argon, Nitrogen and hydrocarbon gases.

[0044] More preferably, the conditions for depositing and forming the metal Cr transition layer include: argon gas flow rate 100 sccm-400 sccm, nitrogen gas flow rate 0 sccm, hydrocarbon gas flow rate 0 sccm, deposition time 5 min-50 min.

[0045] More preferably, the conditions for depositing and forming the ...

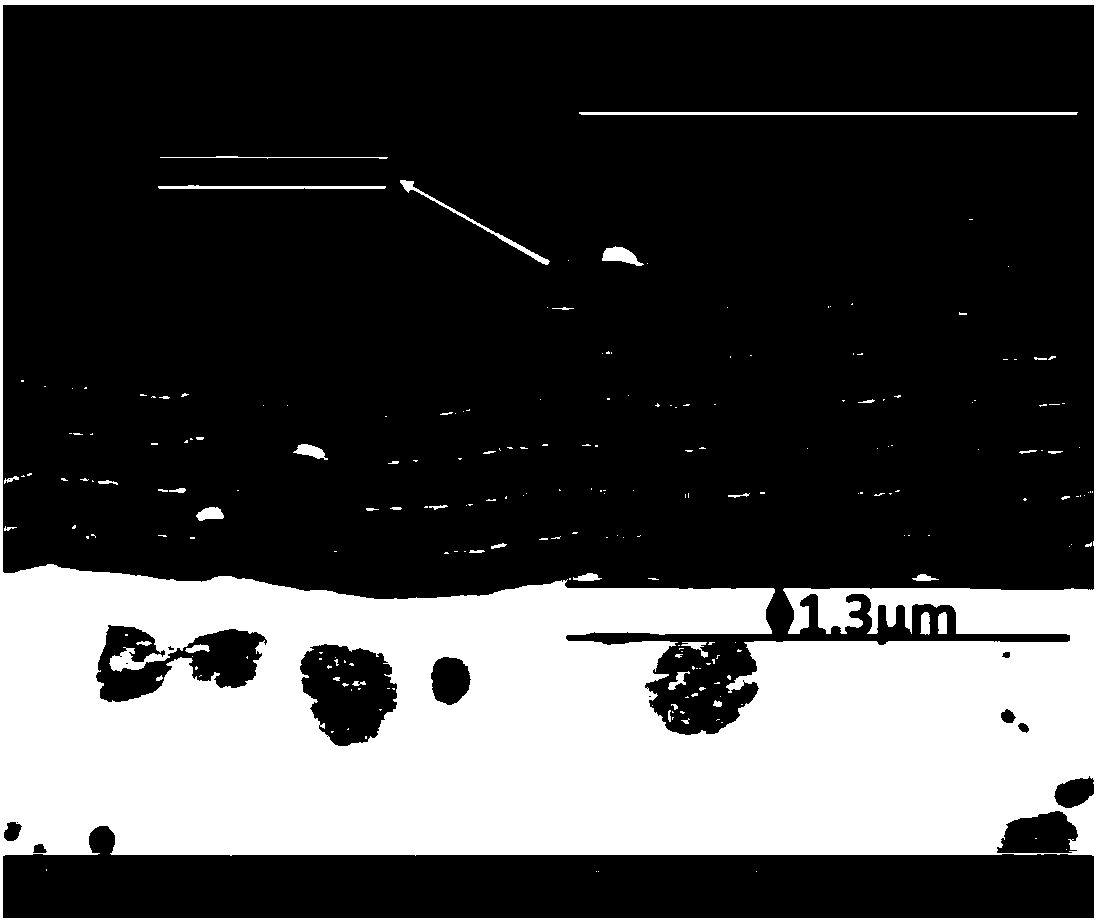

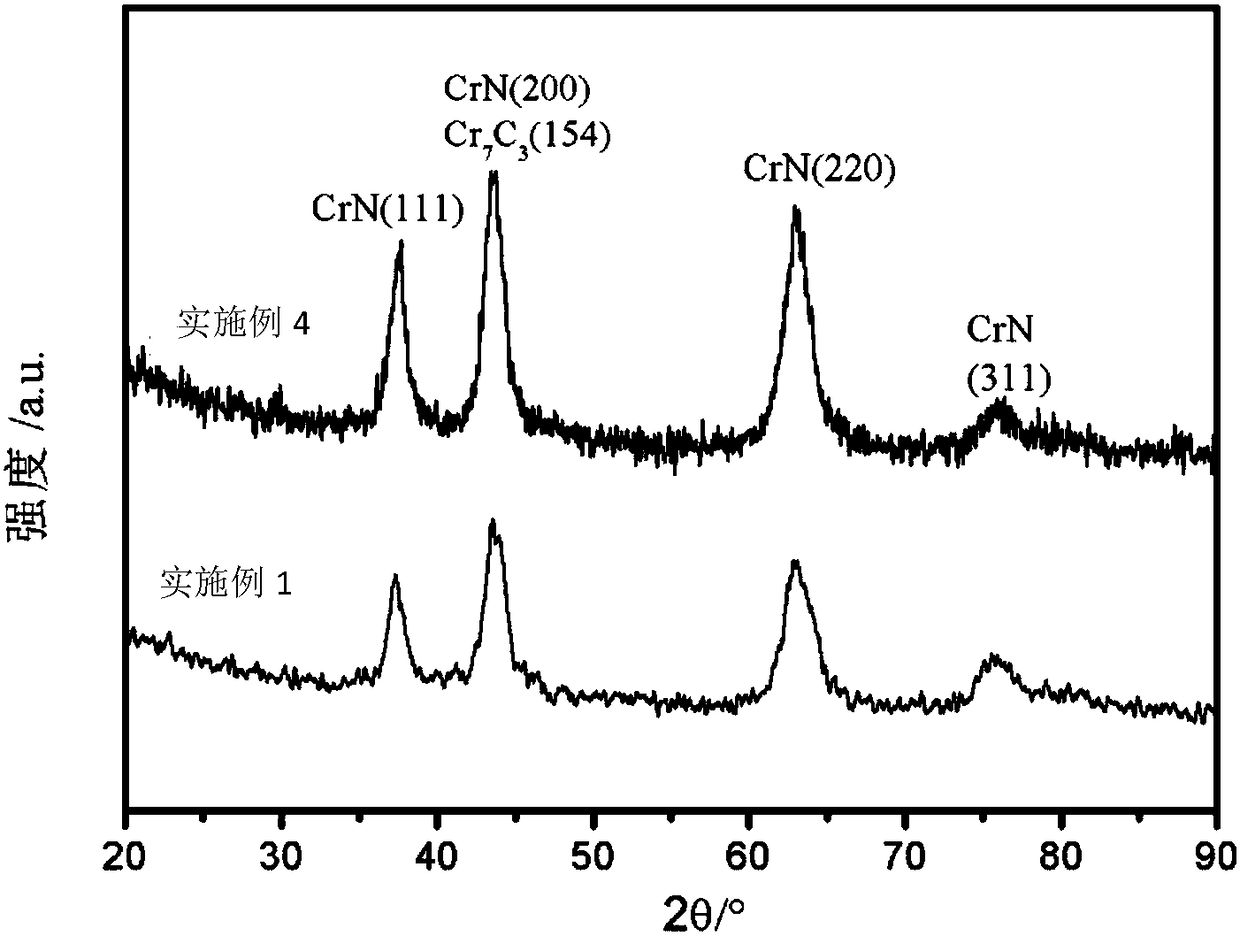

Embodiment 1

[0067] Embodiment 1: the nanometer multilayer piston ring CrCN / Cr coating (also known as nanometer multilayer piston ring coating) of the present embodiment is formed on the metal Cr transition layer on the piston ring parent material and is formed on the metal Cr transition layer The CrCN / Cr layer multilayer structure coating composition. The thickness of the metal Cr transition layer is about 1.3 μm. The total thickness of the CrCN / Cr layer multilayer structure coating is about 10.9 μm.

[0068] The nanometer multilayer piston ring CrCN / Cr coating can be prepared according to the following steps:

[0069] (1) Clean, degrease, and surface activate the base metal of the piston ring. First, use ethanol, acetone and other solvents to clean and degrease the base metal of the piston ring, and then put it into the vacuum chamber of the multi-arc ion plating equipment for argon plasma activation treatment. The flow rate of argon gas is 120 sccm, and the bias voltage is - 1000V, t...

Embodiment 2

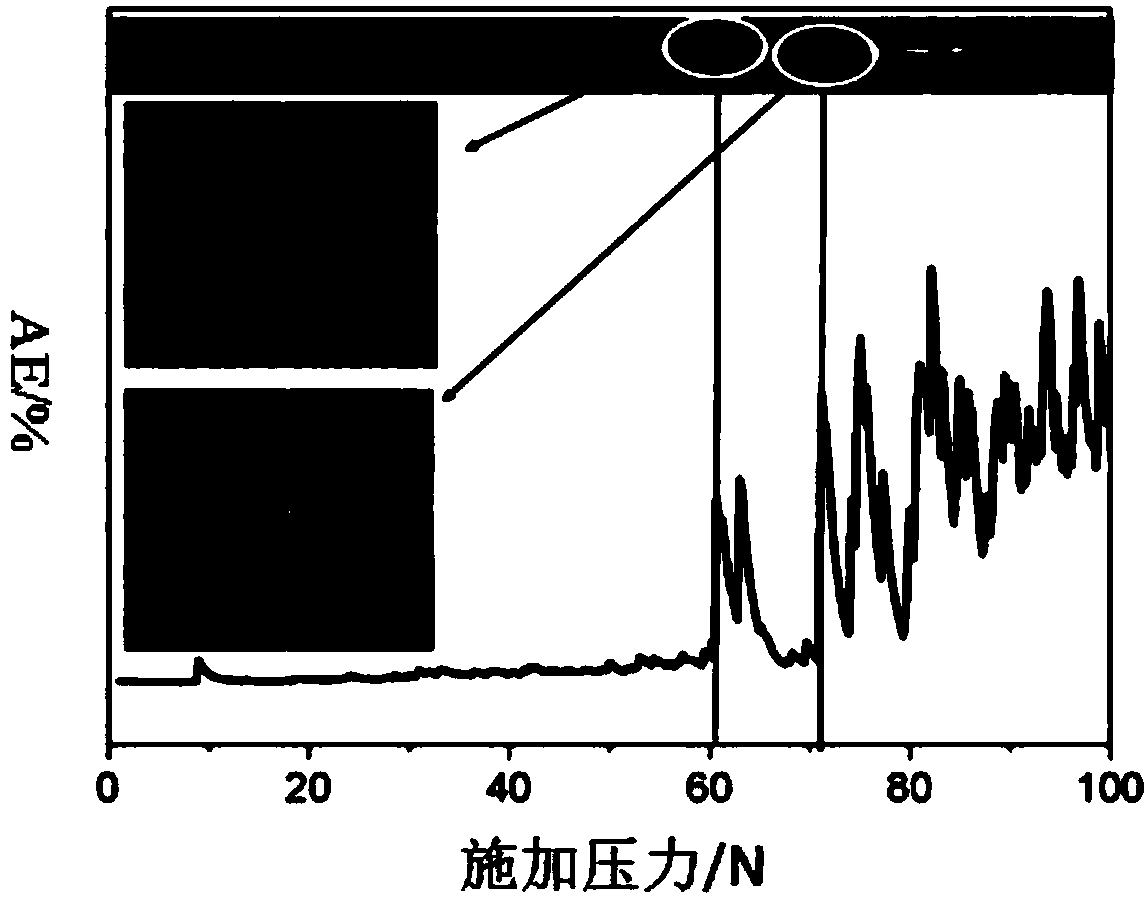

[0088] Embodiment 2: the nanometer multilayer piston ring CrCN / Cr coating (also known as nanometer multilayer piston ring coating) of the present embodiment is formed on the metal Cr transition layer on the piston ring parent material and is formed on the metal Cr transition layer The CrCN / Cr layer multilayer structure coating composition. The thickness of the metal Cr transition layer is about 1.3 μm. The thickness of the CrCN / Cr multilayer structure coating is about 11.8 μm. Tests show that the bonding force between the CrCN / Cr coating and the base material of the piston ring is about 76.8N, the hardness is about 28.4Gpa, and the oil lubrication friction coefficient is about 0.091.

[0089] The nanometer multilayer piston ring CrCN / Cr coating can be prepared according to the following steps:

[0090] (1) Clean, degrease, and surface activate the base metal of the piston ring. First, use ethanol, acetone and other solvents to clean and degrease the base metal of the piston...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com