Flexible three-dimensional porous carbon material and preparation method and application thereof

A three-dimensional porous, carbon material technology, used in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor electrodes, etc., can solve problems such as increasing the diffusion distance and resistance of electrolyte ions and charges, affecting fast charging/discharging capabilities, and reducing capacitor performance. , to achieve the effect of excellent cycle stability, excellent capacitance performance, and improved energy density and power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

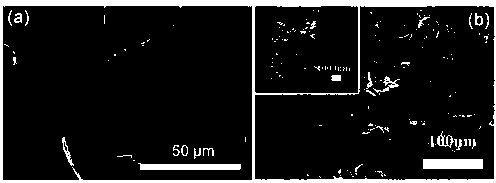

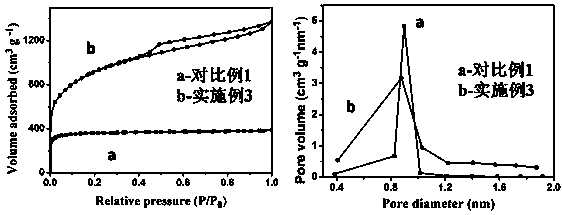

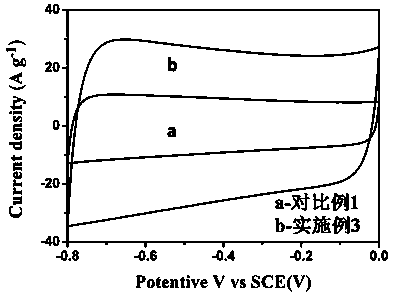

[0037] Embodiment 1: provide the three-dimensional porous carbon material prepared according to the method of the present invention and its application

[0038] Cut a 5 cm × 3 cm × 2 cm piece of melamine foam sponge, ultrasonically clean it with acetone for 30 min, and dry at 100°C; weigh 40 parts of coal tar pitch and dissolve it in 30 parts of tetrahydrofuran; weigh 20 parts of KOH and dissolve it in 20 parts of absolute ethanol; The above two solutions were mixed, and the mixed solution was magnetically stirred at room temperature for 10 min, put into a melamine sponge, fully impregnated and evenly absorbed, and then dried; the dried coal tar pitch foam-sponge composite was transferred to a ceramic crucible, and placed in a tube furnace , under the protection of Ar, heated to 900 °C for carbonization and activation; the resulting carbon material was soaked in 2 M HCl solution for 10 h, filtered, and vacuum-dried at 110 °C to obtain a three-dimensional porous carbon material....

Embodiment 2

[0040] Embodiment 2: provide the three-dimensional porous carbon material prepared according to the method of the present invention and its application

[0041] Cut a 5 cm × 3 cm × 2 cm piece of melamine foam sponge, ultrasonically clean it with acetone for 10 min, and dry at 70°C. Weigh 20 parts of coal tar pitch and dissolve it in 20 parts of tetrahydrofuran, weigh 80 parts of KOH and dissolve it in 40 parts of absolute ethanol. The above two solutions (tetrahydrofuran and ethanol solution) were mixed, and the mixed solution was magnetically stirred at room temperature for 10 min, put into a melamine sponge, fully impregnated and evenly absorbed, and then dried; the dried coal tar pitch foam-sponge composite was transferred to a ceramic crucible, placed in a tube furnace at N 2Under protection, it was heated to 800 °C for pyrolysis; the obtained carbon material was soaked in 2M HCl solution for 10 h, filtered, and vacuum-dried at 100 °C to obtain a three-dimensional porous c...

Embodiment 3

[0043] Embodiment 3: provide the three-dimensional porous carbon material prepared according to the method of the present invention and its application

[0044] Cut a 5 cm × 3 cm × 2 cm piece of melamine foam sponge, ultrasonically clean it with acetone for 10 min, and dry it at 100°C. Weigh 40 parts of coal tar pitch and dissolve it in 30 parts of tetrahydrofuran, weigh 60 parts of KOH and dissolve it in 30 parts of absolute ethanol, and The above two solutions (tetrahydrofuran and ethanol solution) were mixed, and the mixed solution was magnetically stirred at room temperature for 10 min, put into a melamine sponge, fully impregnated and evenly absorbed, and then dried; the dried coal tar pitch foam-sponge composite was transferred to a ceramic crucible, placed in a tube furnace at N 2 Under protection, it was heated to 800 °C for pyrolysis; the obtained carbon material was soaked in 2M HCl solution for 10 h, filtered, and vacuum-dried at 110 °C to obtain a three-dimensional...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com