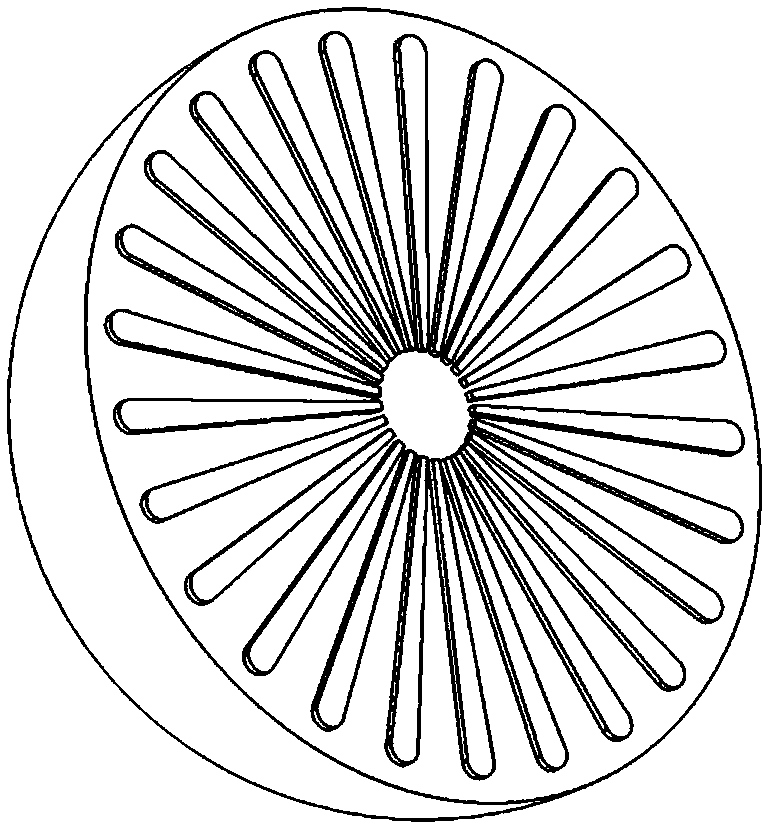

Preparation method of nickel cobalt manganese precursor with special internal structure

An internal structure, nickel-cobalt-manganese technology, applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the problems that the positive electrode material does not have capacity retention and cycle performance, cations are easy to mix, and lithium ions are not easy to deintercalate, etc. , to achieve good capacity retention and cycle performance, reduce lithium-nickel mixed discharge, and reduce energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for preparing a nickel-cobalt-manganese precursor material with a special internal structure includes the following steps:

[0023] (1) Configure a nickel-cobalt-manganese salt solution with a metal ion concentration of 2.0mol / L, configure a sodium hydroxide solution with a concentration of 250g / L, and configure an ammonia concentration of 21%;

[0024] (2) Add deionized water to the sealed reactor until it just floods the lower stirring paddle, the stirring speed is 400rpm, the temperature is raised to 60℃, and nitrogen or argon gas protection is provided for more than 2 hours;

[0025] (3) Add reducing agent, sodium hydroxide solution, ammonia water to the bottom solution, adjust the ammonia concentration to 8.0~10.0g / L, pH value of 10.0~12.0, and the mass of reducing agent to 5% of the total mass of the three metal ions ;

[0026] (4) Add the nickel cobalt manganese salt solution, sodium hydroxide solution and ammonia water to the reaction kettle at the same time, a...

Embodiment 2

[0030] A method for preparing a nickel-cobalt-manganese precursor material with a special internal structure includes the following steps:

[0031] (1) Configure a nickel-cobalt-manganese salt solution with a metal ion concentration of 1.0mol / L, configure a sodium hydroxide solution with a concentration of 150g / L, and configure an ammonia concentration of 10%;

[0032] (2) Add deionized water to the sealed reactor until it just floods the lower stirring paddle, the stirring speed is 300 rpm, the temperature is raised to 50 ℃, and nitrogen or argon gas protection is passed for more than 2 hours;

[0033] (3) Add reducing agent, sodium hydroxide solution, ammonia water to the bottom liquid, adjust the ammonia concentration to 6.0~8.0g / , pH value of 10.0~12.0, and the mass of reducing agent to 0.1% of the total mass of the three metal ions;

[0034] (4) Add the nickel cobalt manganese salt solution, sodium hydroxide solution and ammonia water to the reaction kettle at the same time, and m...

Embodiment 3

[0038] A method for preparing a nickel-cobalt-manganese precursor material with a special internal structure includes the following steps:

[0039] (1) Configure a nickel-cobalt-manganese salt solution with a metal ion concentration of 3.0mol / L, configure a sodium hydroxide solution with a concentration of 300g / L, and configure a ammonia concentration of 30%;

[0040] (2) Add deionized water to the sealed reaction vessel until it just floods the lower stirring paddle, the stirring speed is 500 rpm, the temperature is raised to 70 ℃, and nitrogen or argon gas protection is provided for more than 2 hours;

[0041] (3) Add reducing agent, sodium hydroxide solution, ammonia water to the bottom solution, adjust the ammonia concentration to 10.0~12.0g / L, pH value of 10.0~12.0, and the mass of reducing agent to 10% of the total mass of the three metal ions ;

[0042] (4) Add the nickel cobalt manganese salt solution, sodium hydroxide solution, and ammonia water to the reaction kettle at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com