Flue gas desulfurizing system and method using flue gas desulfurizing system to desulfurize flue gas

A desulfurization system and flue gas technology, applied in the field of flue gas desulfurization system and flue gas desulfurization, can solve the problems of excessive and unsatisfactory emissions, and achieve the effects of clean flue gas, strong absorption capacity and low technology investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

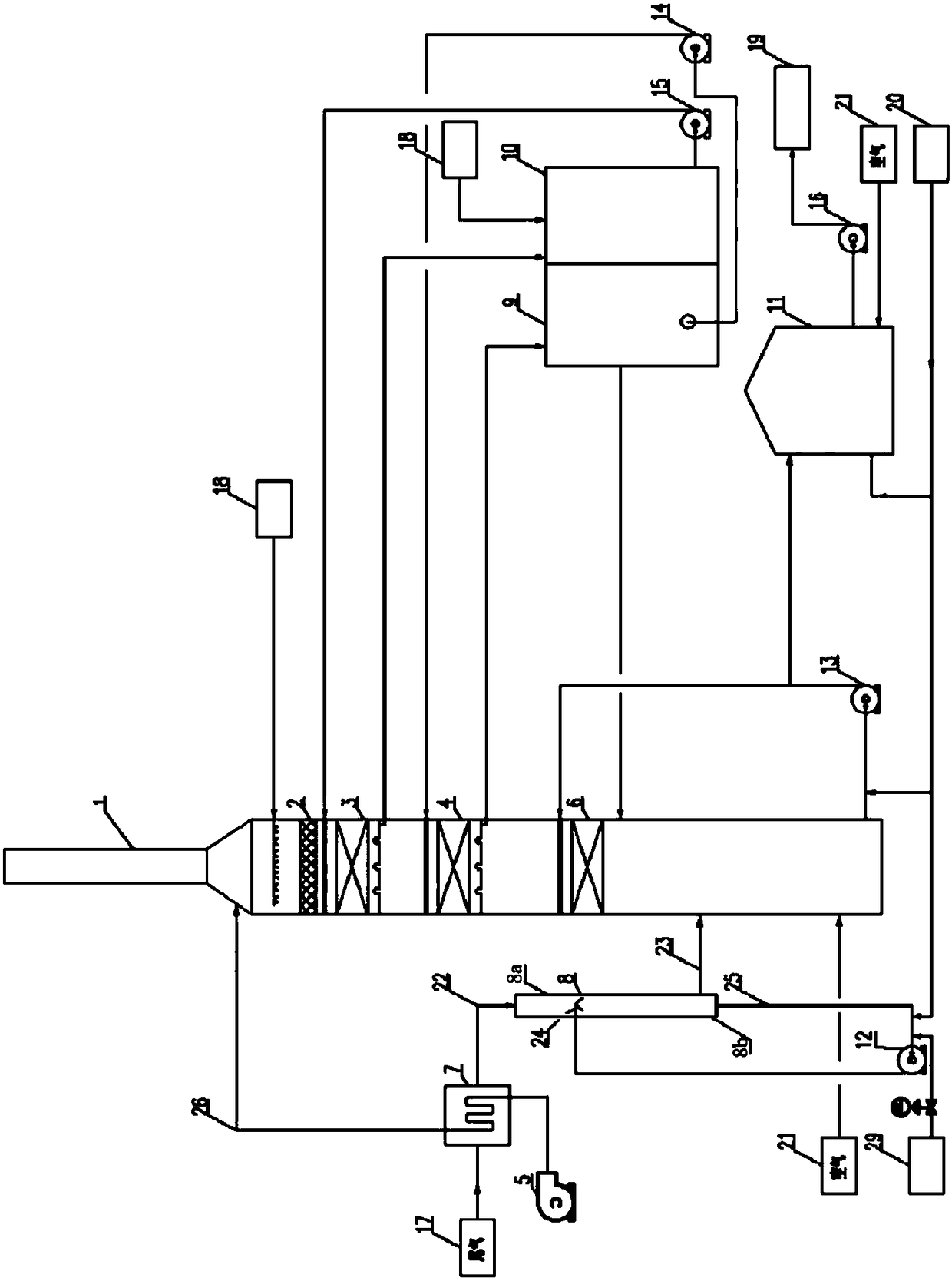

[0035] Such as figure 1 As shown, a flue gas desulfurization system includes a quenching section 8, an absorption section and a chimney 1.

[0036] The quenching section 8 is composed of a spray area 8a and a liquid storage tank 8b which communicate with each other. The spray area 8a includes a tubular shell and a spray layer 24, and the tubular shell is a vertical pipe; the liquid storage tank 8b is located at the bottom of the quenching section 8. In the quenching section 8, the spraying area 8a is provided with a spraying layer 24 at the entrance of the flue gas, and the quenching circulating liquid sprayed from the spraying layer 24 has the same flow direction as the flue gas in the spraying area 8a, and the quenching circulating liquid and the flue gas The gas is in contact with the flow. The bottom of the liquid storage tank 8b is provided with a quenched circulating liquid outlet, and the spray layer 24 is connected with the quenched circulating liquid outlet at the bo...

Embodiment 2

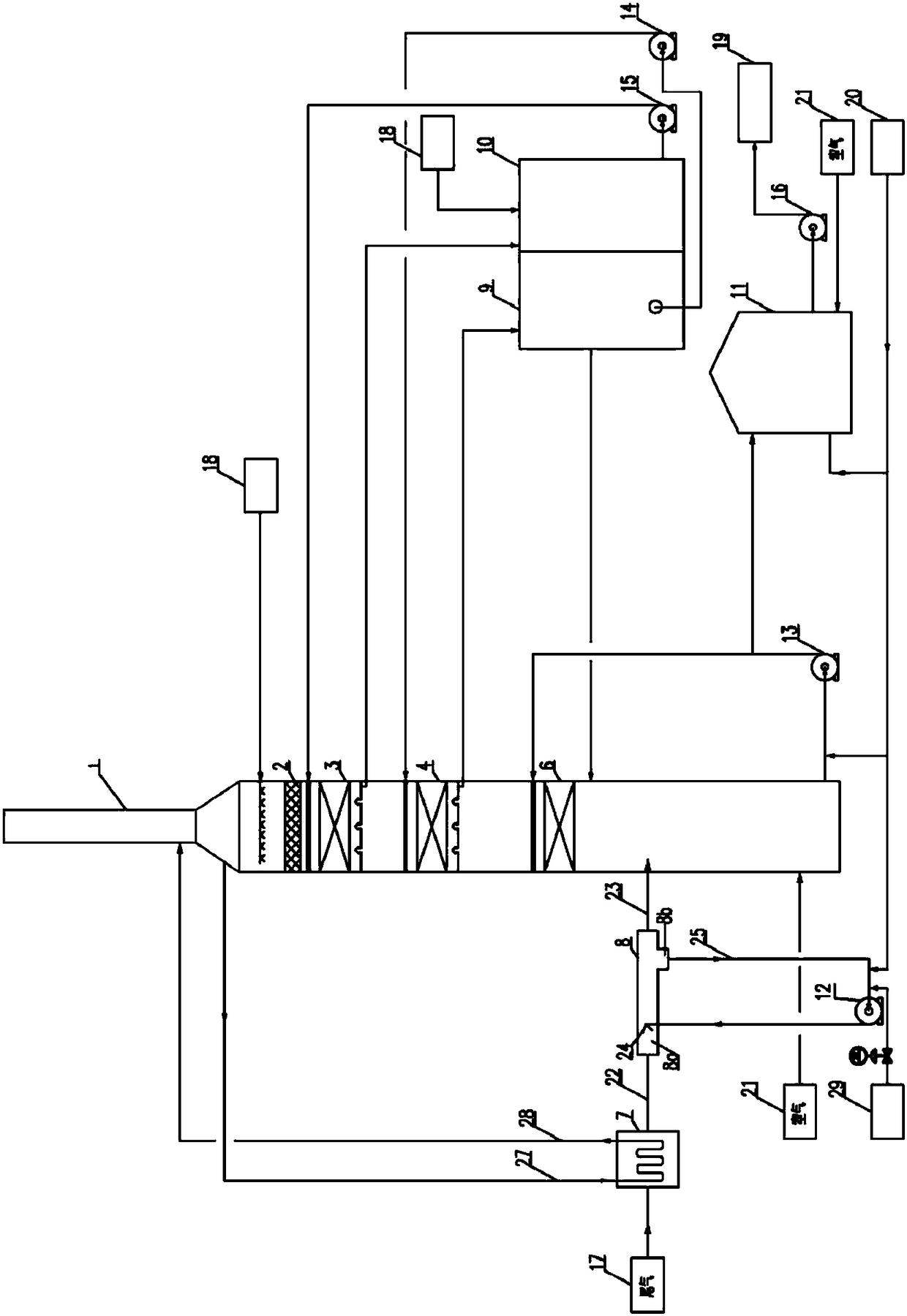

[0064] Such as figure 2 As shown, in addition to replacing the vertical tubular shell of the spray area 8a in Embodiment 1 with a horizontal tubular shell, the exhaust gas flows horizontally in the spray area 8a, the gas-liquid in the spray area 8a is countercurrently contacted, and the exhaust gas The waste heat exchanges heat with the purified flue gas 27 at the top of the tower, so that the temperature of the purified flue gas at the top of the tower is raised to 110-220°C to obtain hot flue gas 28, and then the hot flue gas 28 is discharged to the atmosphere through the chimney, and the rest are the same as in Example 1. This will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com