Preparation method of high-dispersity nano-apatite

A high-dispersion, apatite technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of low solubility of phosphorylated cyclodextrin, increase of experimental cost, environmental pollution, etc., and achieve good interface combination performance, short response time, and the effect of expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

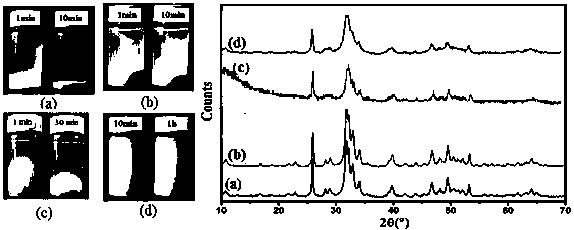

Embodiment 1

[0016] Example 1: Dissolve 17.36 g of carboxylated β-cyclodextrin in 200 ml of water, add 8.86 g of calcium nitrate tetrahydrate and dissolve in 100 ml of water, stir for 3 hours, then add 8.55 g of sodium phosphate dodecahydrate and dissolve in 100 ml of water ml of water, slowly add it dropwise to the above solution, adjust the pH value to about 10 with 10 wt% sodium hydroxide, heat and stir at 70 °C for 4 hours, let stand for 48 hours, wash 5 times with deionized water, and then wash with ethanol Wash 3 times and dry for later use.

Embodiment 2

[0017] Example 2: Dissolve 5.79 g of carboxylated β-cyclodextrin in 300 ml of water, add 26.58 g of calcium nitrate tetrahydrate and dissolve in 300 ml of water, stir for 2 hours, then add 25.63 g of sodium phosphate dodecahydrate and dissolve in 150 ml of water ml of water, slowly add it dropwise to the above solution, adjust the pH value to about 12 with 15 wt% sodium hydroxide, heat and stir at 80°C for 6 hours, let it stand for 48 hours, wash 5 times with deionized water, and then wash with ethanol Wash 3 times and dry for later use.

Embodiment 3

[0018] Example 3: Dissolve 7.74 g of carboxylated α-cyclodextrin in 100 ml of water, add and dissolve 17.70 g of calcium nitrate tetrahydrate in 200 ml of water, stir for 3 hours, then add 17.07 g of sodium phosphate dodecahydrate and dissolve in 50 ml of water was slowly added dropwise to the above solution, the pH was adjusted to about 10 with 10 wt% sodium hydroxide, heated and stirred at 60 °C for 4 hours, after standing for 48 hours, washed 5 times with deionized water, and then used Washed 3 times with ethanol and dried for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com