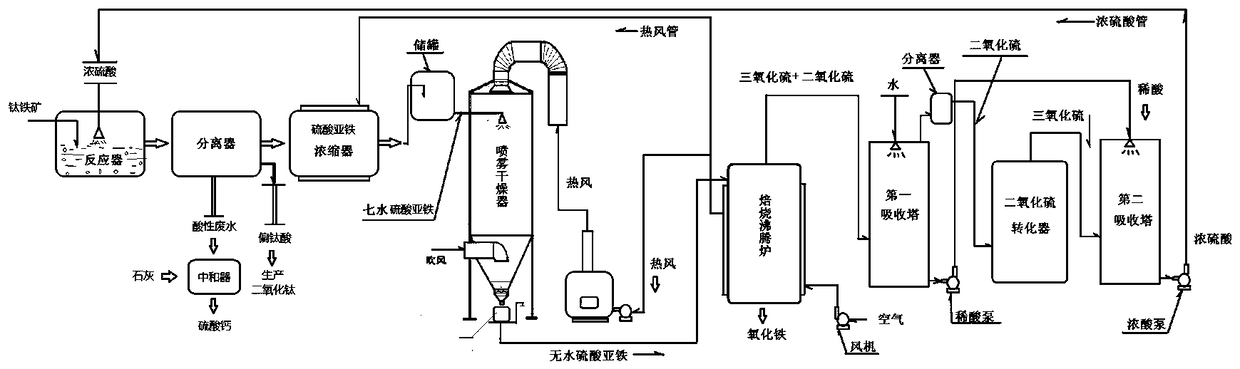

Energy-saving joint production method and equipment of titanium dioxide plant for producing titanium dioxide, sulfuric acid and iron ore concentrate

A technology of joint production and titanium dioxide plant is applied in the field of comprehensive utilization of titanium dioxide production and waste residue and wastewater, which can solve the problems of complicated process, long decomposition time of ferrous sulfate and high cost of comprehensive utilization, and achieves simple equipment, low moisture content and cost saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

[0032] Putting ilmenite and concentrated sulfuric acid into a reactor for reaction, the reaction temperature is 500-700° C., and the reaction time is 6-10 hours. Titanyl sulfate is obtained, and titanyl sulfate is hydrolyzed to generate metatitanic acid and ferrous sulfate, which are separated in a separator to obtain solid metatitanic acid, ferrous sulfate and acidic wastewater, and acidic wastewater is added to lime to react to produce calcium sulfate, which is used in cement plants Gypsum raw material; solid metatitanic acid is used to produce titanium dioxide; ferrous sulfate heptahydrate is concentrated in a concentrator to dehydrate it to generate ferrous sulfate tetrahydrate (FeSO 4 4H20), ferrous sulfate trihydrate (FeS0 4 ·3H 2 0), ferrous sulfate dihydrate (FeSO 4 2H 2 0), the heating temperature in the drum heater is 650-800°C, and the heating time is 30-120 minutes; after that, it enters the spray drying tower to obtain anhydrous ferrous sulfate or ferrous sulfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com