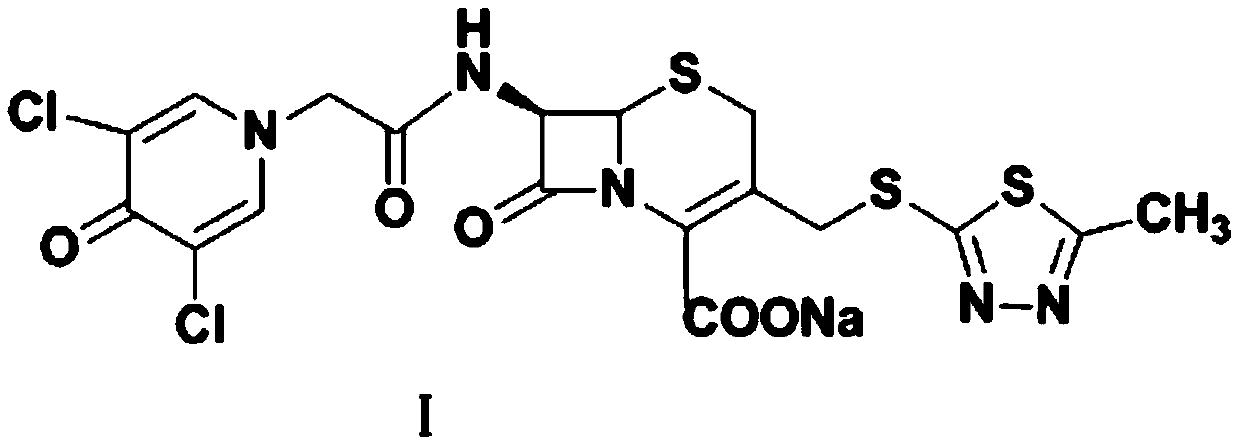

A kind of preparation method of cefazedone sodium compound

A technology of cefazedone sodium and its compound, which is applied in the field of preparation of anti-infective drug cefazedone sodium compound, can solve the problems of many side reactions, reduced total product yield, low yield of final product, etc., and achieves simple process route, The effect of high total yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

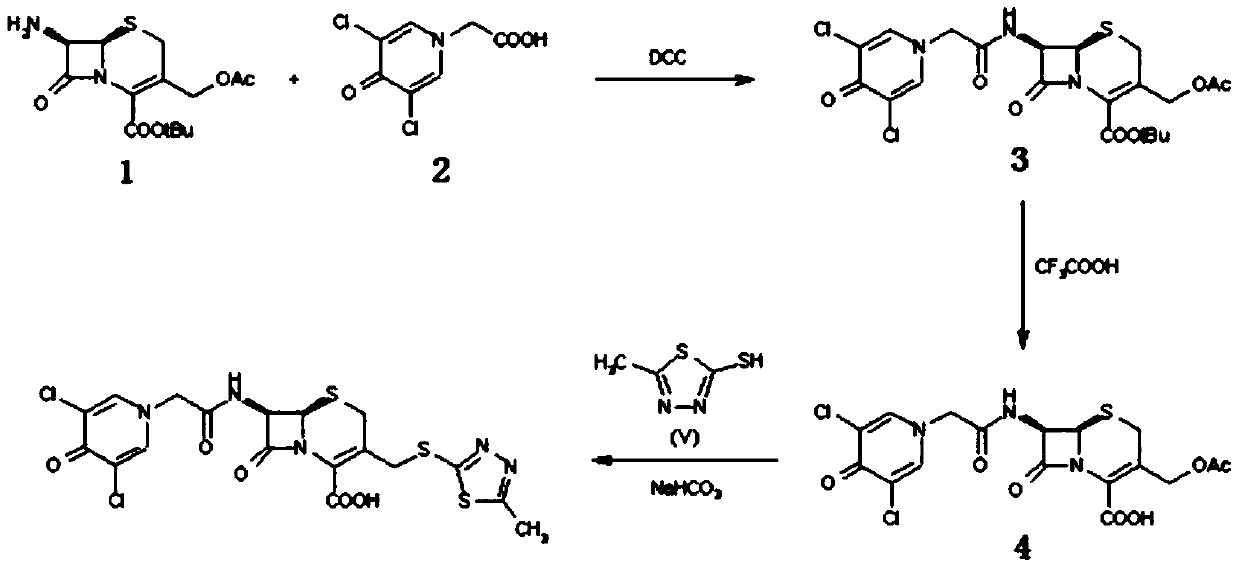

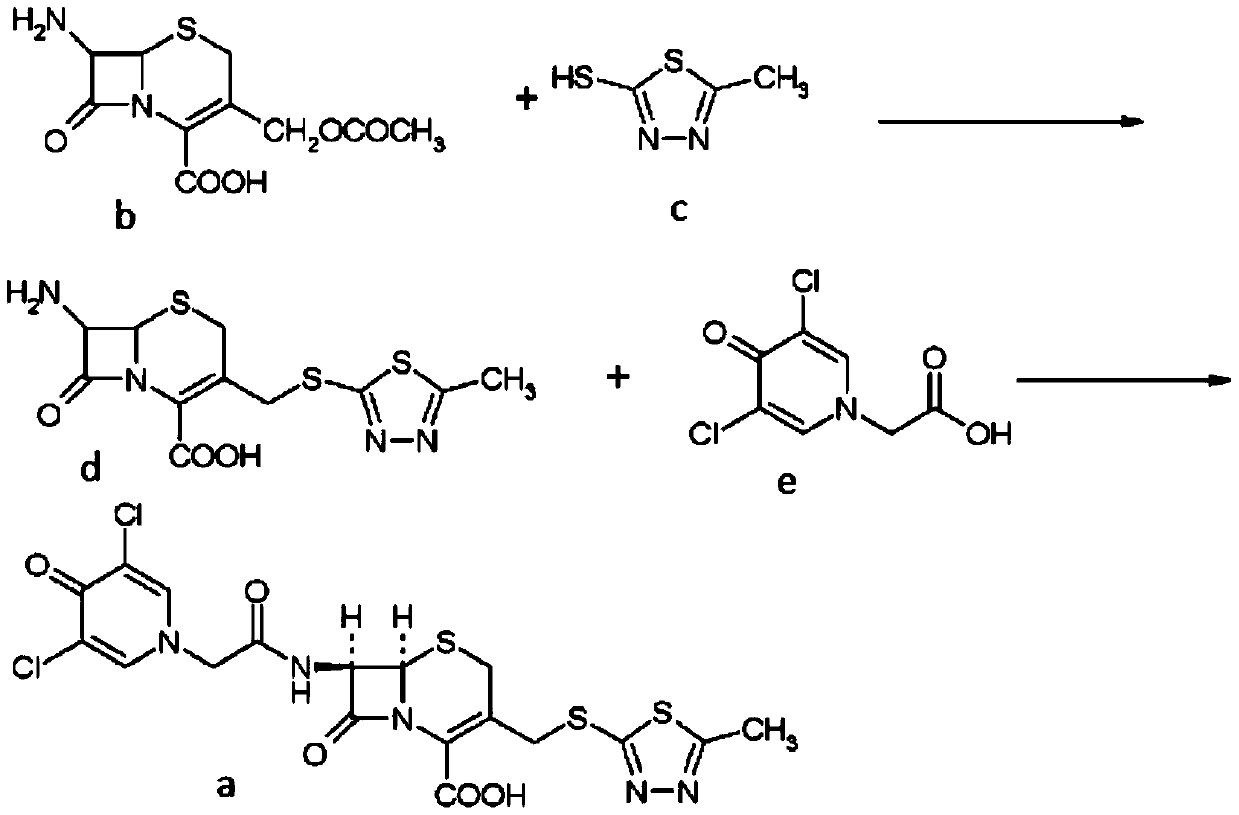

Method used

Image

Examples

Embodiment 1

[0031] Preparation of compound IV

[0032] Add 27.23g of 7-ACA(Ⅱ), 13.22g of compound III and 600ml of N,N-dimethylformamide to the reaction flask, control the temperature at 40-50℃ and stir the reaction for 3h. TLC monitors the completion of the reaction, and then removes it by evaporation Solvent, add 800ml ethyl acetate and 800ml saturated sodium bicarbonate to the obtained oil, separate the layers, dry the organic layer over anhydrous sodium sulfate, filter, concentrate the filtrate, and recrystallize with ether to obtain a solid 31.87g with a molar yield of 92.4% , HPLC purity is 99.86%.

Embodiment 2

[0034] Preparation of compound IV

[0035] Add 27.23g of 7-ACA(Ⅱ), 13.22g of compound III, and 600ml of dichloromethane to the reaction flask, control the temperature at 40-50℃ and stir for 3h. TLC monitors the completion of the reaction, then evaporates and removes the solvent to obtain an oily substance Add 800ml ethyl acetate and 800ml saturated sodium bicarbonate, separate the layers, the organic layer is dried over anhydrous sodium sulfate, filtered, the filtrate is concentrated and recrystallized with ether to obtain a solid 31.34g, molar yield 90.8%, HPLC purity 99.78% .

Embodiment 3

[0037] Preparation of compound IV

[0038] Add 27.23g of 7-ACA(Ⅱ), 14.54g of compound III and 600ml of N,N-dimethylformamide to the reaction flask, control the temperature at 40-50℃ and stir the reaction for 3h. TLC monitors that the reaction is complete, and then it is removed by evaporation. Solvent, add 800ml ethyl acetate and 800ml saturated sodium bicarbonate to the obtained oily substance, separate the layers, dry the organic layer over anhydrous sodium sulfate, filter, concentrate the filtrate, and recrystallize it with ether to obtain 32.29g solid with a molar yield of 93.6% , HPLC purity is 99.85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com