High-modulus and high-temperature-resistant bismaleimide resin composition

A bismaleimide resin and bismaleimide technology are applied in the field of high modulus and high temperature resistant bismaleimide resin compositions, and can solve the problem of high processing temperature, high molding cost and high energy consumption and other problems, to achieve the effect of improving compressive strength, solving high curing temperature, ensuring heat resistance and processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The invention is a high-modulus high-temperature-resistant bismaleimide resin composition, which consists of 50 parts by mass of bismaleimide monomer, 5 parts of cyano resin, and 15 parts of vinylaniline , 30 parts of allyl compounds, 0.5 parts of ketoxime accelerator, 0.1 part of imidazole accelerator, the bismaleimide monomer selected for the above bismaleimide resin composition is N, N'-(4,4'-methylenediphenyl)bismaleimide (MDA-BMI), N,N'-(4-methyl-1,3-phenylene)-bismaleimide The combination of two components of imide (TDA-BMI) according to the mass ratio of 2:1; the cyano resin is polyphthalonitrile resin; the vinyl aniline is 3-vinyl aniline; the allyl compound is di Allyl bisphenol A; the oxime accelerator is dimethylglyoxime; the imidazole accelerator is aminoimidazole.

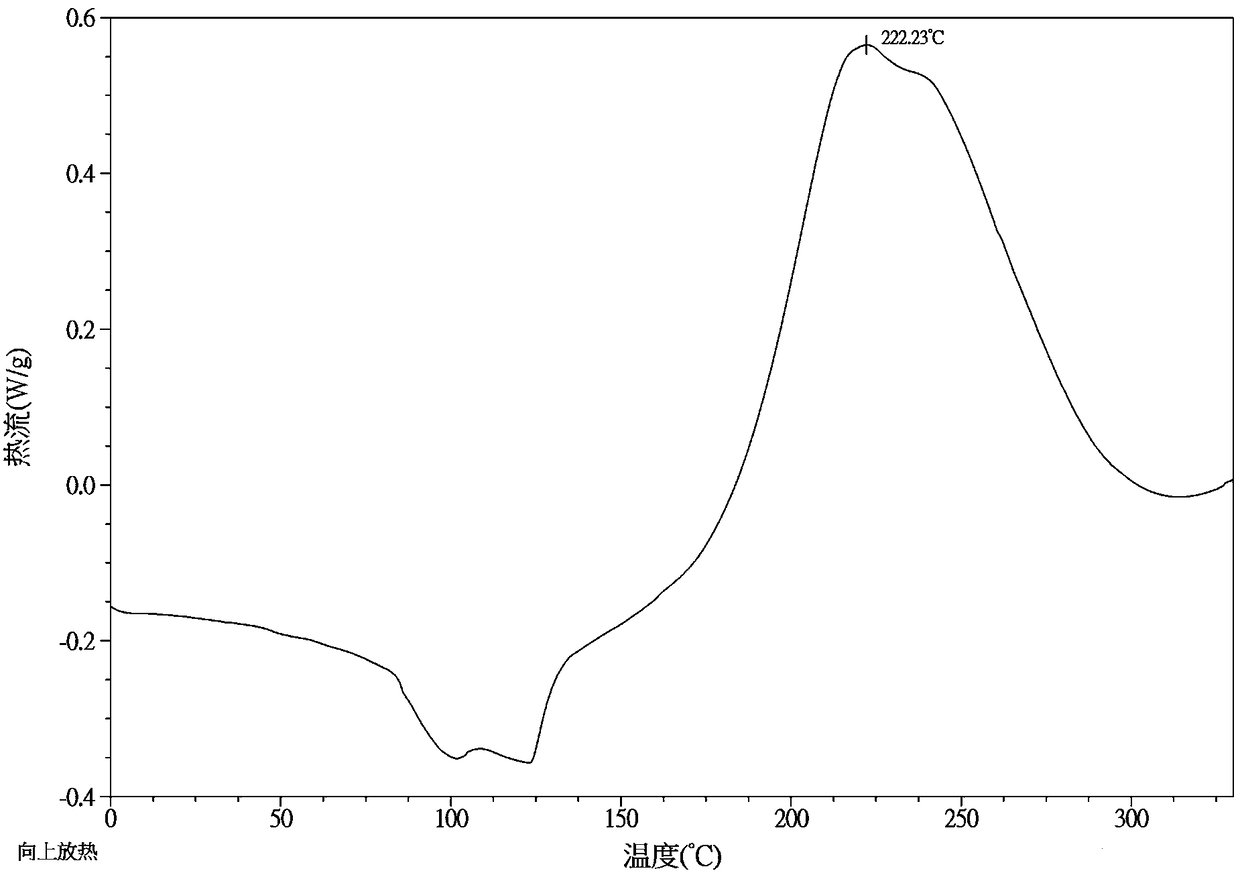

[0028] attached figure 1 It is the DSC curve of the obtained bismaleimide resin composition according to the scanning speed of 10° C. / min. It can be seen from the curve that the curing peak t...

Embodiment 2

[0034] The difference between this example and Example 1 is that the selected bismaleimide monomer is N,N'-(4-methyl-1,3-phenylene)-bismaleimide imine (TDA-BMI). Others are the same as in Example 1.

Embodiment 3

[0036] This embodiment differs from the first and second embodiments in that the selected cyano resin is a phthalonitrile monomer. Others are identical with embodiment one and embodiment two.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com