Pure epoxy powder coating and preparation method thereof

An epoxy powder and coating technology, applied in the coating field, can solve the problems of poor chemical resistance, poor decoration, poor leveling, etc., and achieve the effects of good mechanical properties, good decoration, and good chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

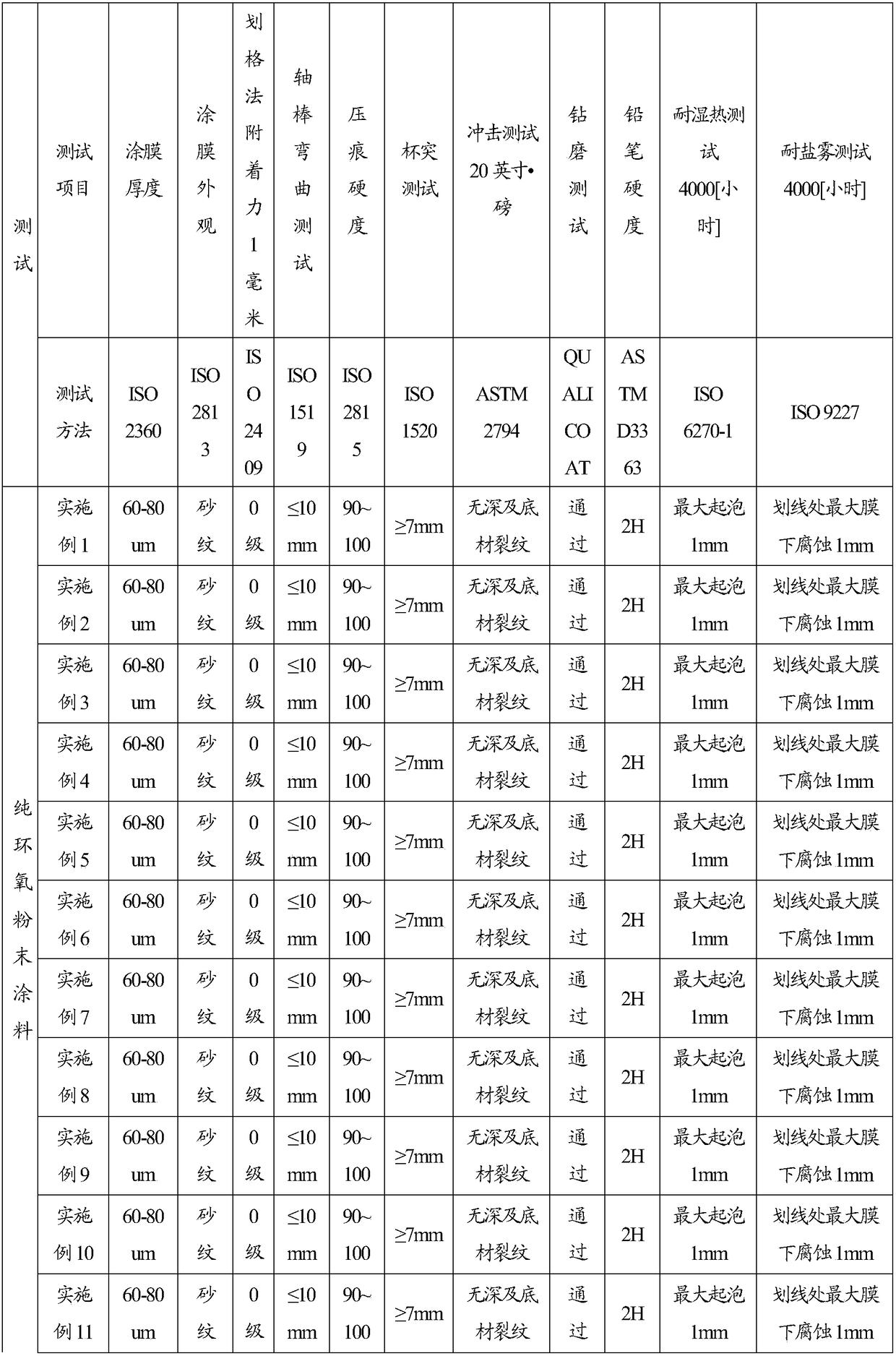

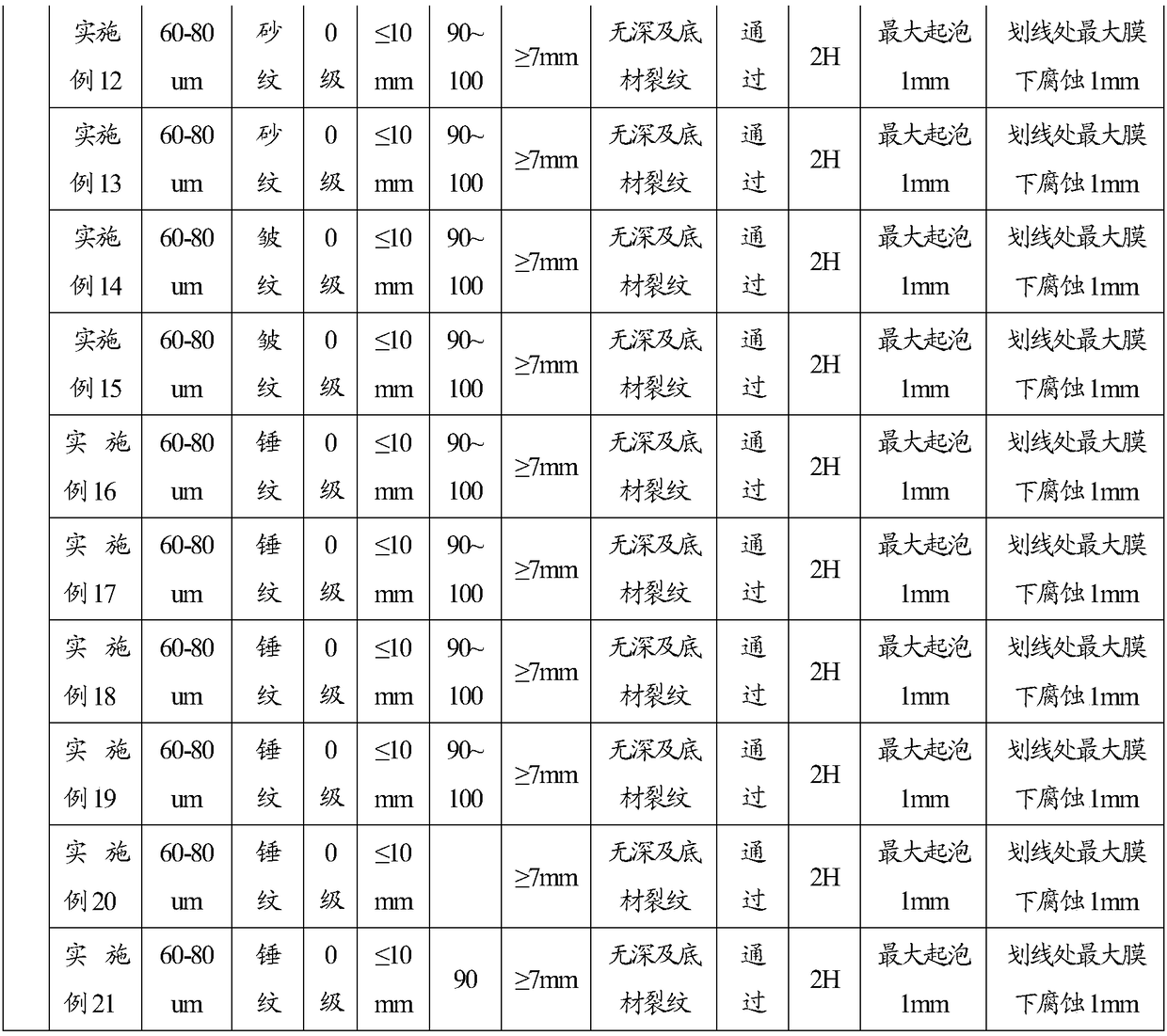

Examples

Embodiment 1

[0025] A pure epoxy powder coating: in parts by weight, the pure epoxy powder coating components include: 75 parts of epoxy resin, 7 parts of curing agent, 35 parts of titanium dioxide, 40 parts of barium sulfate, 1 part of acrylic acid leveling agent 1 part, acrylic wetting agent 1 part, benzoin 1 part, stearic acid 1 part, polyethylene wax 1 part, amide wax 1 part, polytetrafluoroethylene wax 1 part, charge regulator 1 part, organic bentonite 1 part , 1 part of catalyst, 5 parts of matting agent.

[0026] Wherein, the curing agent is an epoxy curing agent; the catalyst is imidazole and its derivatives. The pure epoxy powder coating composition also includes: pigments. 0-15 parts of the pigment.

[0027] The preparation method of the above pure epoxy powder coating includes: premixing the pure epoxy powder coating components, washing, extruding, pulverizing, and mixing to obtain the pure epoxy powder coating.

[0028] Wherein, the crushing process specifically includes: co...

Embodiment 2

[0030] The difference between this embodiment and Example 1 is that in parts by weight, the pure epoxy powder coating components include: 50 parts of epoxy resin, 5 parts of curing agent, 10 parts of titanium dioxide, 10 parts of barium sulfate, all 0.1 part of acrylic leveling agent, 0.1 part of acrylic wetting agent, 0.1 part of benzoin, 0.1 part of stearic acid, 0.1-1 part of polyethylene wax, 0.1-1 part of amide wax, 0.1 part of polytetrafluoroethylene wax, 0.1 part of charge regulator, 0.1 part of organic bentonite, 0.1 part of catalyst, and 0.1 part of matting agent.

Embodiment 3

[0032] The difference between this embodiment and Example 1 is that in parts by weight, the pure epoxy powder coating components include: 75 parts of epoxy resin, 7 parts of curing agent, 35 parts of titanium dioxide, 40 parts of barium sulfate, acrylic acid 1 part of leveling agent, 1 part of acrylic wetting agent, 1 part of benzoin, 1 part of stearic acid, 1 part of polyethylene wax, 1 part of amide wax, 1 part of polytetrafluoroethylene wax, 1 part of charge regulator, 1 part of organic bentonite, 1 part of catalyst.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap