Colored photosensitive resin composition, color filter and image display device

A technology of photosensitive resin and composition, applied in the directions of instruments, optics, filters, etc., can solve the problems of decreased adhesion, pattern errors, and pattern layers that cannot be applied with color filters, etc., and achieves excellent surface curing degree, The effect of excellent flatness or reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0231] In a three-necked round-bottomed flask containing a cooling tube and a stirrer, add polyethylene glycol monoacrylate (2-[2-[2-[2-(2-hydroxyethoxy)ethoxy]ethoxy] Ethoxy] ethyl 2-acrylate) 103.0 parts by weight are put into 600 parts by weight of toluene, while stirring, drop into 0.1 parts by weight of 4-(dimethylamino)pyridine (4-(Dimethylamino)pyridine), dicyclohexyl - 0.1 part by weight of dicyclohexyl-carbodiimide, 32.5 parts by weight of 3-Mercaptopropionic acid.

[0232] The reflux reaction was continued for 12 hours. During the reaction, TLC was constantly checked to confirm that the reaction was complete, and 121 parts by weight of the compound of Chemical Formula 2 were obtained.

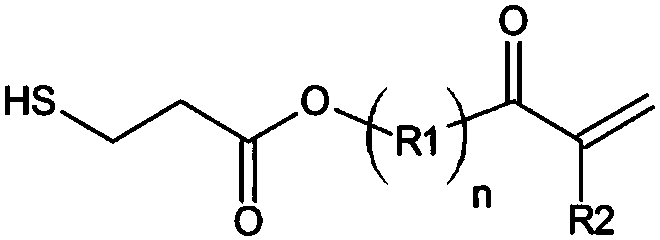

[0233] [chemical formula 2]

[0234]

Synthetic example 2

[0236] In a three-necked round-bottomed flask containing a cooling tube and a stirrer, add polyethylene glycol monomethacrylate (32-hydroxy-3,6,9,12,15,18,21,24,27,30-deca Oxadocodecane-1-yl-2-methyl-2-acrylate, 32-hydroxy-3,6,9,12,15,18,21,24,27,30-decaoxadotriacontan-1-yl -2-methylprop-2-enoate) 174.1 parts by weight are put into 600 parts by weight of toluene, and 0.1 parts by weight of 4-(dimethylamino)pyridine (4-(Dimethylamino)pyridine) and dicyclohexyl-carbon 0.1 parts by weight of dicyclohexyl-carbodiimide, and 32.5 parts by weight of 3-Mercaptopropionic acid.

[0237] The reflux reaction was continued for 12 hours. During the reaction, TLC was constantly checked to confirm that the reaction was complete, and 187 parts by weight of the compound of Chemical Formula 3 were obtained.

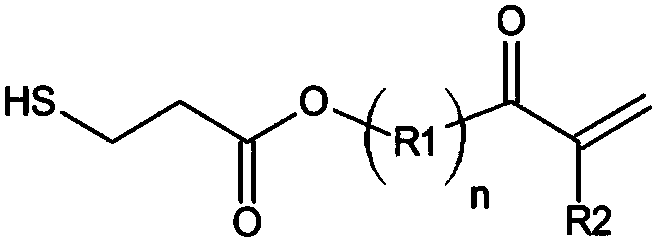

[0238] [chemical formula 3]

[0239]

Synthetic example 3

[0241]In a three-necked round-bottomed flask containing a cooling tube and a stirrer, add polyalkylene glycol monomethacrylate (19-hydroxy-12,15,18-trimethyl-2,4,6,8,11 ,14,17-Heptaoxanonadecan-1-yl 2-methyl-2-2 acrylate, 19-hydroxy-12,15,18-trimethyl-2,4,6,8,11,14, 17-heptaoxanonadecan-1-yl2-methylprop-2-2enoate) 144.7 parts by weight were put into 600 parts by weight of toluene, and 0.1 parts by weight of 4-(dimethylamino)pyridine (4-(Dimethylamino)pyridine) was dropped into while stirring, Dicyclohexyl-carbodiimide (dicyclohexyl-carbodiimide) 0.1 weight part, 3-mercaptopropionic acid (3-Mercaptopropionic acid) 32.5 weight parts.

[0242] The reflux reaction was continued for 12 hours. During the reaction, TLC was constantly confirmed to confirm that the reaction was complete, and 160 parts by weight of the compound of Chemical Formula 4 were obtained.

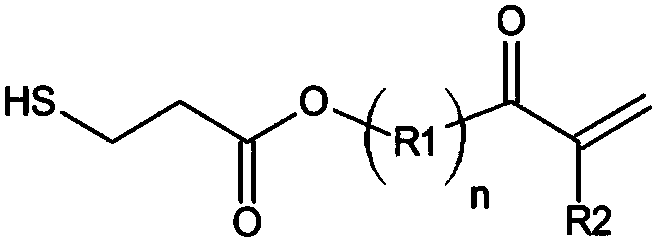

[0243] [chemical formula 4]

[0244]

[0245] Production of colored photosensitive resin composition: Examples 1-6 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com