Catalyst used for fixed bed ethyne hydrochlorination reactions and using method

A technology for acetylene hydrochlorination and catalysts, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve harsh conditions, many synthesis steps, and difficult industrial applications And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

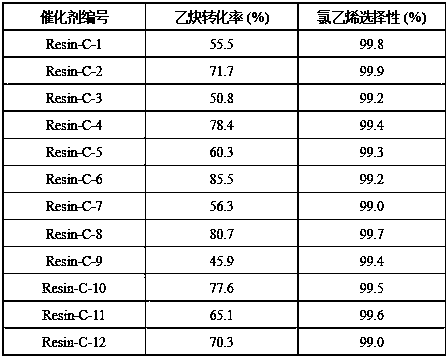

Examples

Embodiment 1

[0030] 1) Dry 10 g of D380 at 100 °C for 4 hours to obtain dried D380;

[0031] 2) Dissolve 1 g of copper chloride in 19 g of deionized water with stirring at 30 °C to obtain an impregnating solution with a mass fraction of 5%, and then impregnate the impregnating solution on 5 g of dry D380 by incipient wetness impregnation method, seal the static After 6 hours, the sample was completely dried at 60°C to obtain a precursor;

[0032] 3) In the flow of N 2 Under gas, 5 g of the precursor was heated to 200 °C at a heating rate of 5 °C / min in a tube furnace for 1 hour, then raised to 500 °C at a heating rate of 1 °C / min and maintained for 3 hours, and then dropped to At room temperature, the catalyst Resin-C-1, N 2 The gas volumetric space velocity is 180 h -1 .

Embodiment 2

[0034] 1) Dry 10 g of D382 at 105 °C for 4 hours to obtain dried D382;

[0035] 2) Dissolve 6 g of copper chloride in 14 g of deionized water with stirring at 50 °C to obtain an impregnating solution with a mass fraction of 30%, and then use the incipient wetness impregnation method to impregnate the impregnating solution on 5 g of dry D382, seal the static After 6 hours, the sample was completely dried at 85°C to obtain a precursor;

[0036] 3) Under the flowing He gas, the temperature of 5 g precursor was raised to 250 °C at a heating rate of 10 °C / min in a tube furnace for 1 hour, and then the temperature was raised to 900 °C at a heating rate of 3 °C / min and maintained 3 hours, then down to room temperature to obtain catalyst Resin-C-2, He gas volume space velocity is 300 h -1 .

Embodiment 3

[0038] 1) Dry 10 g of D392 at 100–105 °C for 4 hours to obtain dried D392;

[0039]2) Dissolve 1 g of thiourea in 19 g of deionized water with stirring at 30 °C to obtain an impregnation solution with a mass fraction of 5%, and then use the incipient wetness impregnation method to impregnate the impregnation solution on 5 g of dry D392, and seal it statically. After 6 hours, the sample was completely dried at 60°C to obtain a precursor;

[0040] 3) Under flowing Ar gas, 5 g of the precursor was heated to 200 °C at a heating rate of 5 °C / min in a tube furnace for 1 hour, and then raised to 500 °C at a heating rate of 1 °C / min and maintained After 3 hours, down to room temperature, the catalyst Resin-C-3 is obtained, and the volume space velocity of Ar gas is 180 h -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com