A kind of reuse method of deactivated catalyst and composite catalyst

A technology for deactivating catalysts and catalysts, applied in catalysts, molecular sieve catalysts, carbon compound catalysts, etc., can solve the problems of inability to completely remove carbon deposits, irreversible deactivation of catalysts, etc., to reduce energy consumption, good catalytic performance, and service life. prolonged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

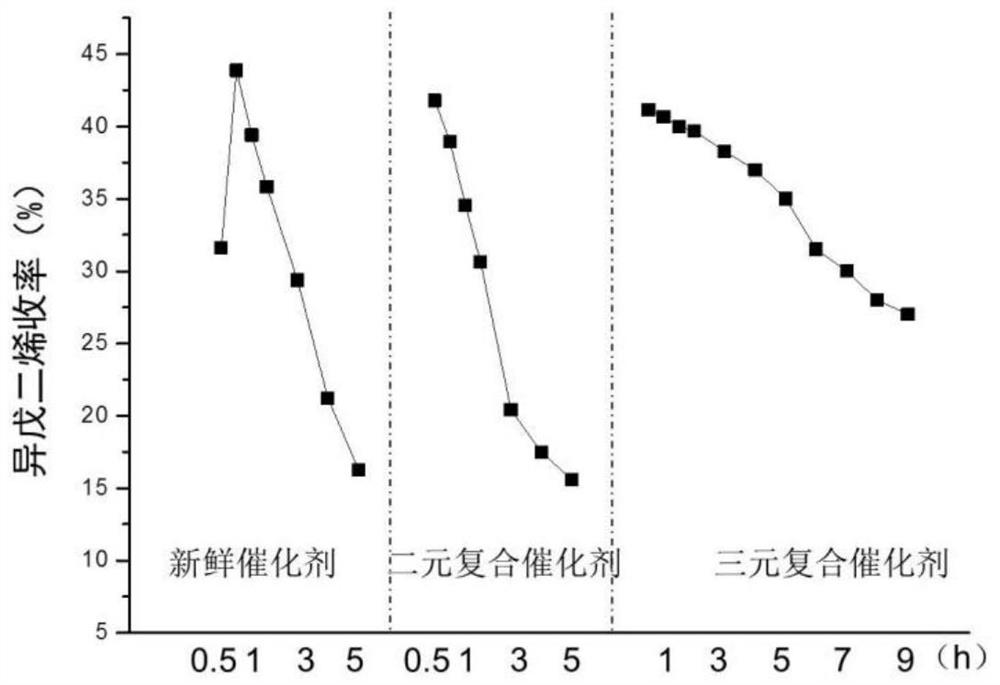

[0047] (1) Weigh 2.5g ammonium molybdate and 0.51g phosphoric acid to make 12ml solution, add 10g SiO 2 , aged at 25°C for 12h, dried at 90°C for 10h, and calcined at 500°C for 4h to obtain MoP / SiO 2 Catalyst (active component loading 20wt%);

[0048] (2) Take 2.0g MoP / SiO 2 It is used for the synthesis of isoprene by the gas phase method of alkenal. The reaction conditions are: a fixed bed under normal pressure, at 250 ° C, with nitrogen (10ml / min) as the internal standard, and the molar ratio of isobutene and formaldehyde is kept at 4:1. Catalyst The contact time is 1.3s, the reaction induction period is 1h, and after the reaction is carried out for 5h, when the yield of isoprene drops to 16%, the catalyst is recovered, and its carbon content is about 25wt%;

[0049] (3) Take 0.8g recovered MoP / SiO 2 Catalyst and 1.2 g fresh MoP / SiO 2 The catalyst is added to the agitator, and the binary composite catalyst is obtained after being uniformly mixed by mechanical stirring;

...

Embodiment 2

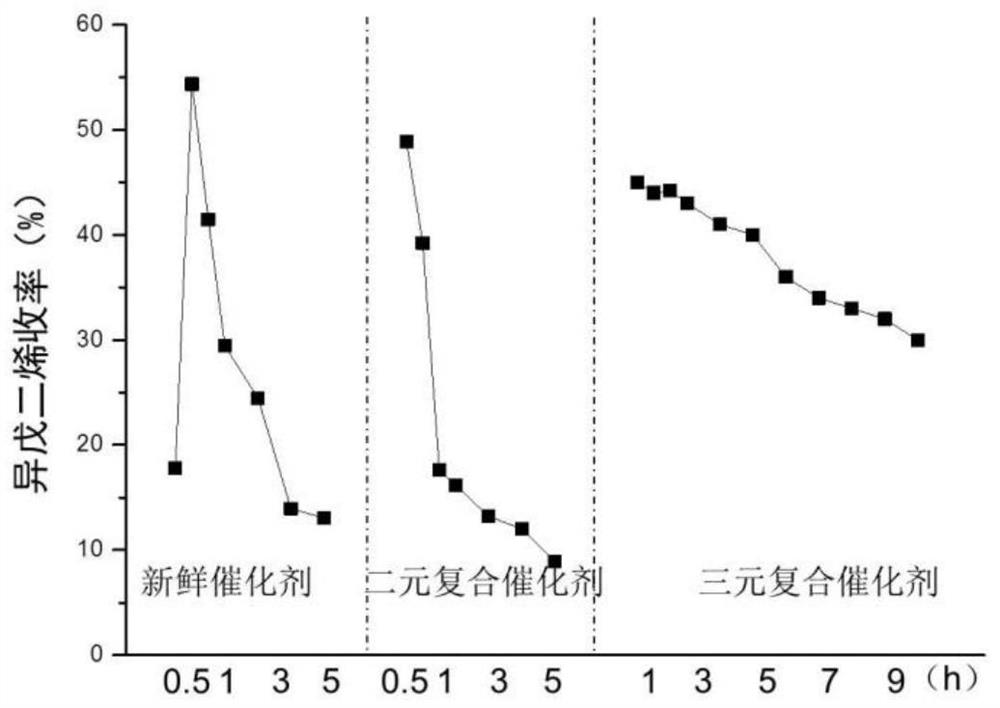

[0054] (1) Weigh 5.0g TiCl 4 Add it into 50ml of water, quickly add 3.6g of phosphoric acid under stirring, add ammonia water to adjust the pH to 4, age at 20°C for 24h, filter, dry at 90°C for 15h, and roast at 450°C for 8h to obtain a TiP catalyst;

[0055] (2) Take 2.0g TiP for the synthesis of isoprene by alkenal gas phase method, the reaction conditions are: fixed bed under normal pressure, at 280°C, with nitrogen (10ml / min) as internal standard, to keep isobutylene and formaldehyde molar The ratio is 9:1, the catalyst contact time is 0.4s, and the reaction induction period is 1h. After the reaction is carried out for 5h, when the yield of isoprene drops to 12%, the catalyst is recovered, and its carbon content is about 14wt%;

[0056] (3) Get the TiP catalyst that 0.8g reclaims and the fresh TiP catalyst of 1.2g and join in the stirrer, obtain binary composite catalyst after mixing by mechanical stirring;

[0057] (4) ZrO 2 0.1g adds (3) gained binary composite catalys...

Embodiment 3

[0061] (1) Weigh 2.5g CrO 3 Dissolve in 10ml of water, add 1.8g of phosphoric acid, stir well and add 10g of SiO 2 , aged at 30°C for 18h, dried at 110°C for 8h, and calcined at 500°C for 5h to obtain CrP / SiO 2 Catalyst (active component loading 28wt%);

[0062] (2) 2.0g CrP / SiO 2 It is used for the synthesis of isoprene by the gas phase method of alkenal. The reaction conditions are: a fixed bed under normal pressure, at 370 ° C, with nitrogen (10ml / min) as the internal standard, and the molar ratio of isobutene and formaldehyde is kept at 5:1. Catalyst The contact time is 1.4s, the reaction induction period is 0.5h, and after the reaction is carried out for 1h, when the yield of isoprene is 34%, the catalyst is recovered, and its carbon content is about 11wt%;

[0063] (3) Take 1.0g of recovered CrP / SiO 2 Catalyst and 1.0 g fresh CrP / SiO 2 The catalyst is added to the agitator, and the binary composite catalyst is obtained after being uniformly mixed by mechanical stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com