A process for preparing environmentally friendly sound barrier sound absorbers by using plant fibers and foundry waste sand

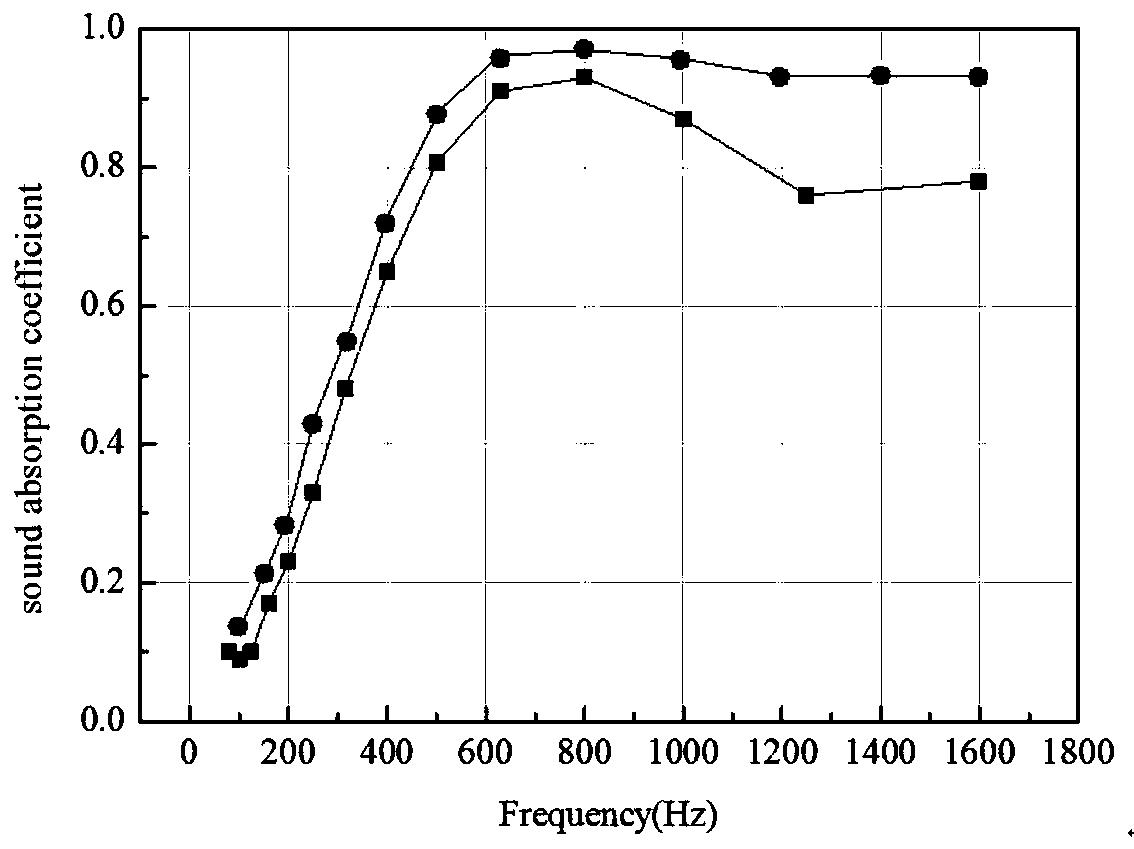

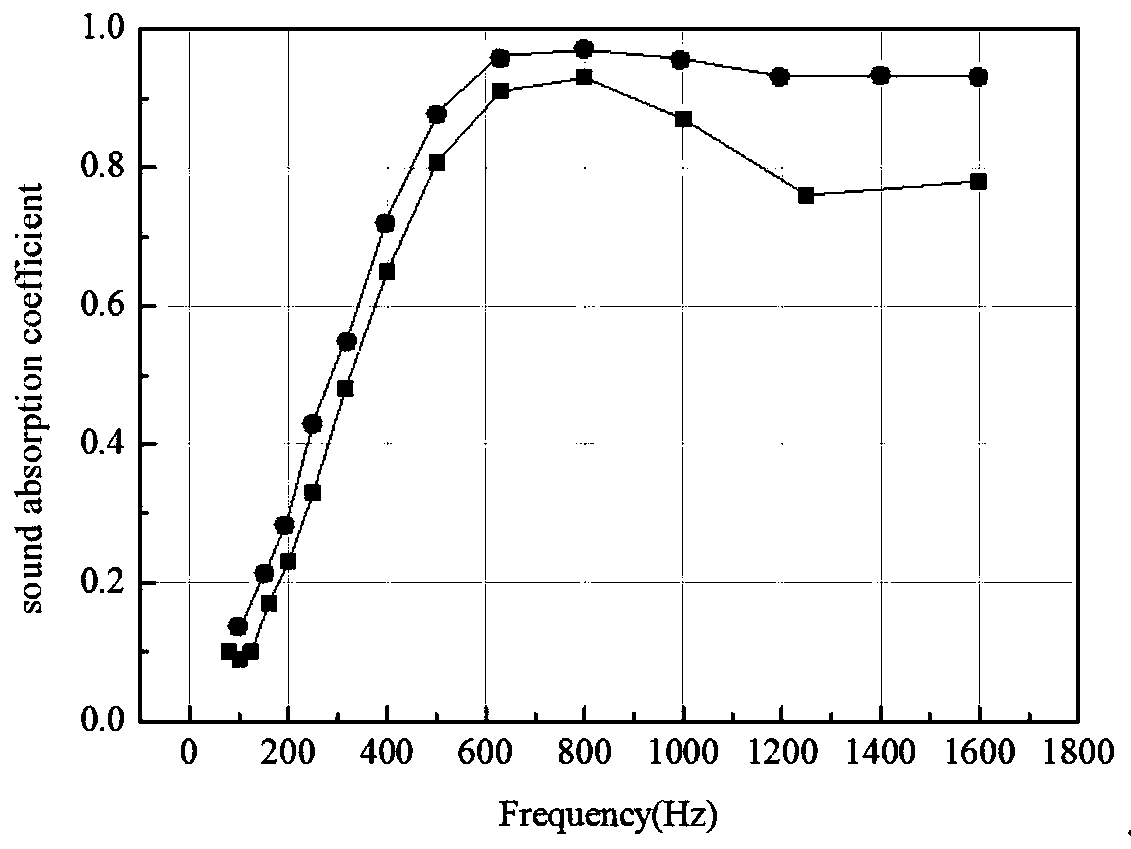

A technology of plant fiber and foundry waste sand, which is applied in the direction of sound-generating devices, instruments, and layered products. It can solve problems such as poor low-frequency sound absorption performance, and achieve good corrosion resistance, relieve visual fatigue, and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The specific implementation is mainly two parts: (1) the making of plant fiber felt. Pretreatment and production of plant fibers: After collecting plant fibers, they are crushed and chopped into 6-12mm chopped fibers; soaked in alkaline solution for 2 hours; removed and dried; the surface layer is sprayed with coupling agent solution. Mix a certain proportion of water-based epoxy resin with curing agent and rutile titanium dioxide, spray it on the surface-treated plant fiber, and heat-press it. (2) Production of foundry waste sand particle board. For the pretreatment and production of foundry waste sand: sieve the collected foundry waste sand with a sieve size of 0.3 or 0.6mm. Mix a certain proportion of epoxy resin with pretreated foundry waste sand, stir evenly, and press to shape.

[0028] 1) The collected hemp fibers are crushed and chopped to form chopped fibers with a length of about 6-8 mm, which are soaked in 5% NaOH solution for 2 hours, and the soaking tempe...

Embodiment 2

[0036] The specific implementation is mainly two parts: (1) the making of plant fiber felt. Pretreatment and production of plant fibers: After collecting plant fibers, they are crushed and chopped into 6-12mm chopped fibers; soaked in alkaline solution for 2 hours; removed and dried; the surface layer is sprayed with coupling agent solution. Mix a certain proportion of water-based epoxy resin with curing agent and rutile titanium dioxide, spray it on the surface-treated plant fiber, and heat-press it. (2) Production of foundry waste sand particle board. For the pretreatment and production of foundry waste sand: sieve the collected foundry waste sand with a sieve size of 0.3 or 0.6mm. Mix a certain proportion of epoxy resin with pretreated foundry waste sand, stir evenly, and press to shape.

[0037] 1) The collected hemp fibers are crushed and chopped to form chopped fibers with a length of about 6-8 mm, soaked in 5% N1,N10-dimethylindolylethylamine solution for 2 hours, Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com