Preparation method for slow-release polycarboxylate water reducer

A slow-release polycarboxylic acid and water-reducing agent technology, applied in the field of building admixtures, to achieve excellent slump retention effect, excellent water-reducing and dispersing effect, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

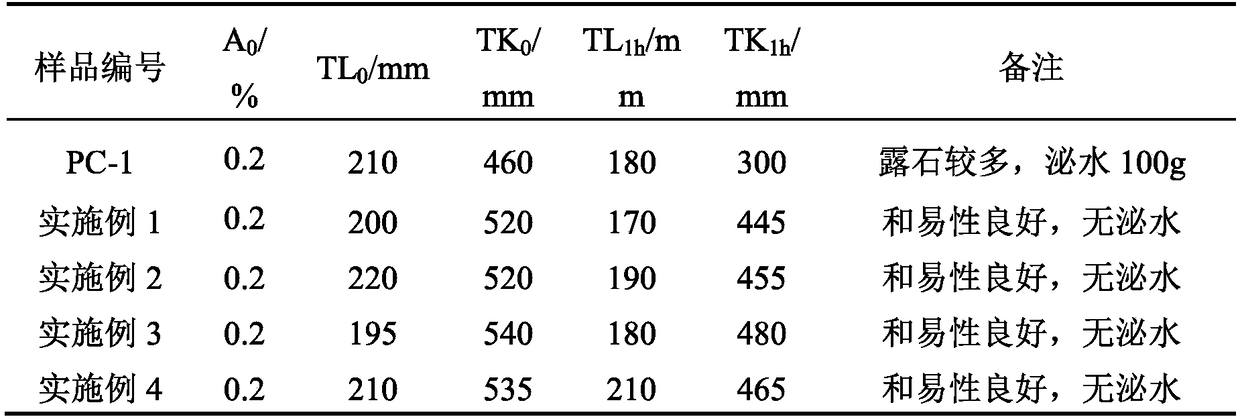

Examples

Embodiment 1

[0022] (1) Add 178g of diethyltoluenediamine, 216 acrylic acid, and 4.5g of 2,4-dimethyl-6-tert-butylphenol into the reaction kettle, under the protection of nitrogen, the microwave is heated to 70°C, and 2.0g is added Solid phosphoric acid and 1.5g ferric sulfate, heated to 115°C, kept for 3 hours for reaction, during which time the water was removed by nitrogen and water, after the reaction, it was cooled to room temperature to obtain the acylated product;

[0023] (2) Add 200g of isopentenyl polyoxyethylene ether into the reaction kettle, microwave heating to 60℃, add 1.4g of dibutyltin phthalate and stir for 8-12min, then add 3g of acrylic acid and 0.7g of liquid caustic at once ;

[0024] (3) Add dropwise a mixture of 6g of acylated product obtained in step (1) and 2g of bis(2,4-dichlorobenzoyl) peroxide to the material obtained in step (2), while adding 4g of hydroxyethyl acrylate A mixture of 16g acrylic acid and 1.5g n-dodecyl mercaptan acetate. The dripping time is 1h. ...

Embodiment 2

[0027] (1) Add 178 diethyl toluene diamine, 344 g methacrylic acid, and 5 g 4-hydroxy piperidinol oxygen radicals into the reaction kettle. Under the protection of nitrogen, the temperature is raised to 70°C by microwave, and 3.0 g solid phosphoric acid and 0.9 Ferric sulfate, heated to 120°C, kept for 3 hours for reaction, during which the water was removed by blowing nitrogen with water, and after the reaction, the temperature was reduced to room temperature to obtain the acylated product;

[0028] (2) Add 200g of methallyl polyoxyethylene ether to the reaction kettle, heat to 60℃ in microwave, add 3g of dibutyltin phthalate and stir for 8-12min, add 5g of acrylic acid and 1.3g of liquid caustic soda ;

[0029] (3) Add dropwise a mixture of 6g of acylated product obtained in step (1) and 1.17g of dioctanoyl peroxide to the material obtained in step (2), while adding 3g of hydroxyethyl acrylate, 18g of acrylic acid and 2.0g of acetic acid. For the mixture of n-dodecyl mercaptan e...

Embodiment 3

[0032] (1) Add 178g diethyltoluenediamine, 258g methacrylic acid, 108g acrylic acid, 3.5g 4-hydroxypiperidinol oxygen radical and 1.5g 2,4-dimethyl-6-tert-butylphenol to the reactor Inside, under the protection of nitrogen, the microwave is heated to 70℃, 3.0g solid phosphoric acid and 0.5g antimony trioxide are added, the temperature is raised to 120℃, and the reaction is kept for 3h. During the period, the water is removed by nitrogen and water. To room temperature to obtain the acylated product;

[0033] (2) Add 200g of methallyl polyoxyethylene ether into the reaction kettle, microwave heating to 60°C, add 2.5g of tetraethyleneimine and stir for 8-12min, add 4g of acrylic acid and 1.1g of liquid caustic at once;

[0034] (3) Add dropwise 10 g of the acylated product obtained in step (1), 1.5 g of peroxide (3,5,5-trimethylhexanoic acid) and 1.1 g of dioctanoyl peroxide to the material obtained in step (2) Add 1g of hydroxyethyl acrylate, 2g of hydroxypropyl acrylate, 10g of acr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com