Ultrahigh-speed laser cladding technology

A laser cladding and ultra-high-speed technology, which is applied in the coating process of metal materials and coatings, can solve the problems of low powder utilization, large heat input, and reduced processing efficiency, and achieve high interface bonding strength and heat input. Small amount, stable powder feeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

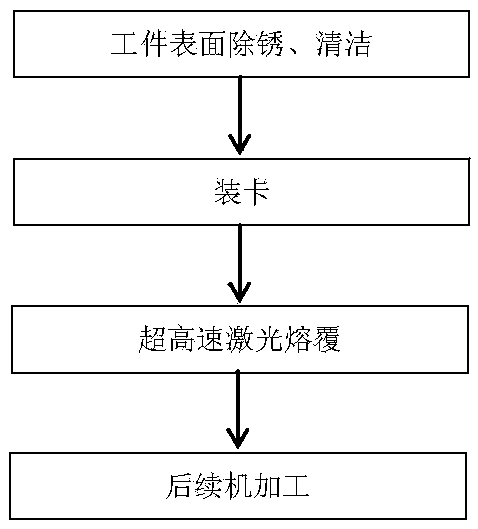

[0041] see figure 1 , providing an ultra-high-speed laser cladding process, specifically adopting the following steps:

[0042] (1) Use sandpaper to wipe and clean the rust spots on the surface of the workpiece to be clad, and clean them with alcohol;

[0043] (2) Load the workpiece into the ultra-high-speed laser cladding machine tool, and clamp it with the chuck;

[0044] (3) Alloy powder for ultra-high-speed laser cladding is used as the cladding material;

[0045] (4) Adjust the Z direction knob of the laser cladding head, set the laser defocus amount to 1~2mm, and the spot size Φ1.0~Φ1.5mm; adjust the X axis of the machine tool (the radial direction of the workpiece) so that the distance between the powder feeding head and the surface of the workpiece is 10~13mm , the powder focus point is 0.2~2mm away from the workpiece surface, and the powder spot size is Φ0.5~1mm;

[0046] (5) Adjust the speed of the powder feeding plate of the powder feeder to control the powder f...

Embodiment 2

[0056] The present invention also provides an ultra-high-speed laser cladding process, which is characterized in that it comprises the following steps:

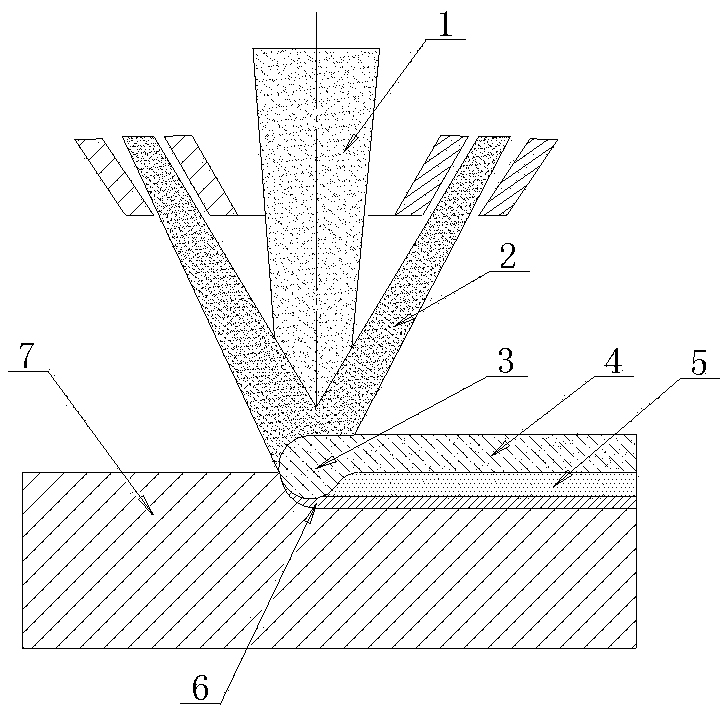

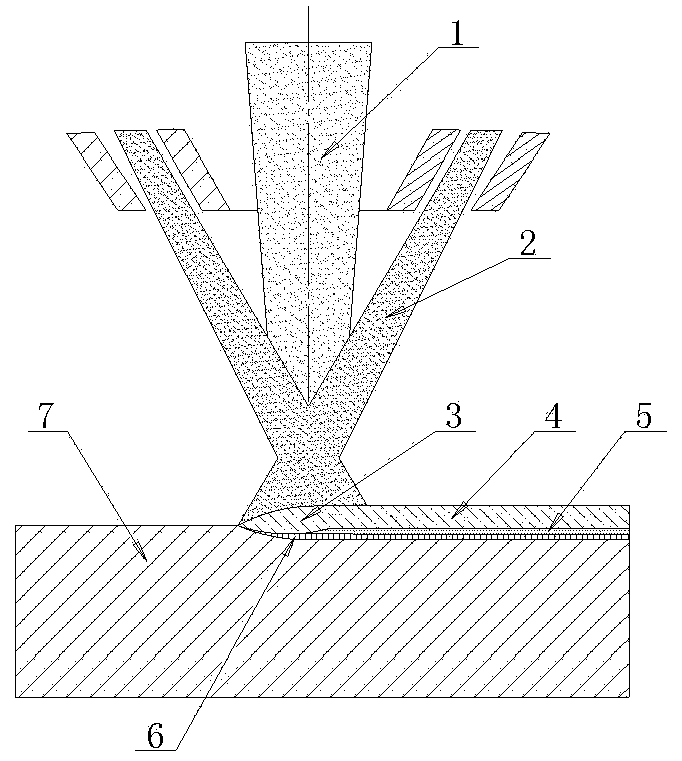

[0057] A small part of the energy of the laser is controlled to act on the upper surface of the base material to form a shallow molten pool 3, and most of the energy of the laser is applied to the alloy powder above the base material;

[0058] The temperature of the alloy powder rises to the melting point and melts before entering the molten pool 3, and drops into the molten pool 3 in the form of droplets to combine with the matrix material.

[0059] It is understandable that since the traditional process focuses the laser energy on the matrix material to melt the dense matrix itself, under the same laser energy, the time it takes to melt the matrix needs to be greatly increased, which greatly limits The cladding speed reduces the utilization rate of the powder. On the contrary, in the present invention, the laser energy is s...

Embodiment 3

[0065] Embodiment 3: This example illustrates the ultra-high-speed laser cladding process of the present invention by taking a columnar part as an example. The base material of the workpiece is 27SiMn, and the size is Φ100mm in diameter x 1000mm in length.

[0066] An ultra-high-speed laser cladding process, specifically adopting the following steps:

[0067] (1) Use sandpaper to wipe and clean the rust spots on the surface of the workpiece to be clad, and clean them with alcohol;

[0068] (2) Load the workpiece into the ultra-high-speed laser cladding machine tool, and clamp it with the chuck and the top;

[0069] (3) The alloy powder for ultra-high-speed laser cladding is used as the cladding material. The mass percentage of the alloy composition is: Cr 16.0%~18.0%, Ni 10.0%~14.0%, Mo 2.0%~3.0%, Mn<2.0%, C≤0.03%, Si≤1.0%, P≤0.045%, S≤0.03%, the rest is Fe; the powder particle size range is 15~45μm, sphericity≥90%, oxygen content≤150ppm, fluidity≤20s / 50g , Hollow powder rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen content | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com