Method for synthesizing zinc-doped ternary material precursor from waste lithium battery through recovery

A technology for waste lithium batteries and ternary materials, applied in the field of ternary material precursors, can solve the problem of inability to remove impurity metals, and achieve the effect of increasing added value and reducing process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for reclaiming and synthesizing a zinc-doped ternary material precursor by waste lithium batteries, comprising the following steps:

[0044] 1. See Table 1 for the composition of the acid immersion solution for the positive electrode material of the waste lithium battery. Use 5% NaOH solution to adjust the pH to 4, add iron powder with 3 times the Cu content and stir at 150rpm for 0.5h, then add 1.2 times the amount of hydrogen peroxide, stirring and reacting at the same rate for 0.5 to 1 hour can remove other doping elements.

[0045] Table 1 (unit: g / L)

[0046] mn

Ni

co

SO 4 2-

Na +

Li +

Al

Fe

Cu

Zn

Pb

Si

12.92

14.36

23.08

366.4

0.038

5.33

2.11

0.44

0.060

0.094

0

0.038

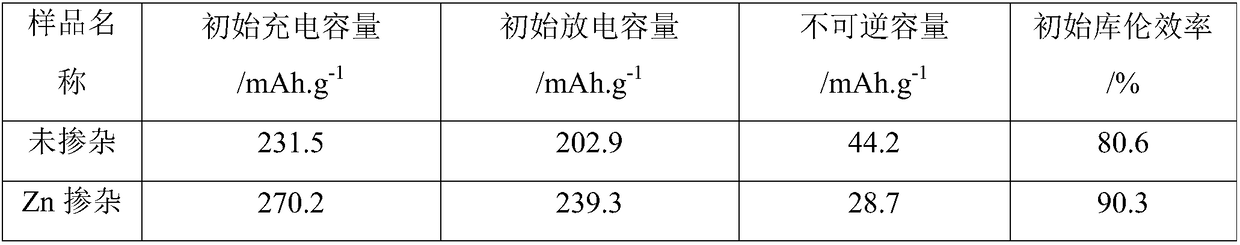

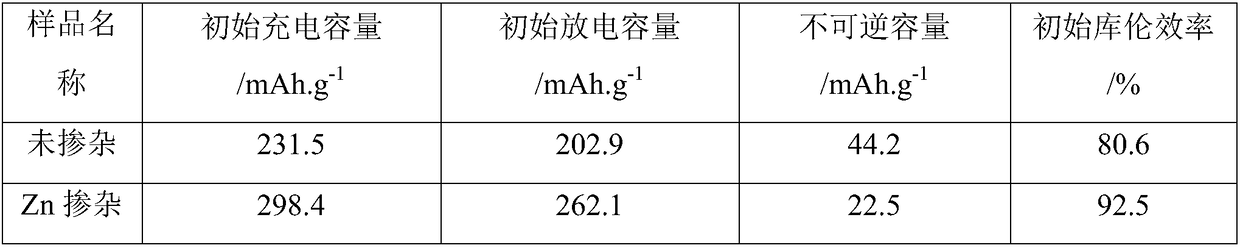

[0047] 2. See Table 2 for the composition of the pickling solution after removing other doping elements. Take 200mL of pickling solution after removing impurities, add 8.15gNiSO 4 .6H ...

Embodiment 2

[0056] A method for reclaiming and synthesizing a zinc-doped ternary material precursor by waste lithium batteries, comprising the following steps:

[0057] 1. See Table 4 for the composition of the acid dipping solution for the positive electrode material of the waste lithium battery. Use 5% NaOH solution to adjust the pH to 4, add iron powder with 3 times the Cu content and stir at 150rpm for 0.5h, then add 1.2 times the amount of hydrogen peroxide, other doping elements can be removed after stirring and reacting at the same rate for 0.5h.

[0058] Table 4 (unit: g / L)

[0059] mn

Ni

co

SO 4 2-

Na +

Li +

Al

Fe

Cu

Zn

Pb

Si

12.92

14.36

23.08

366.4

0.038

5.33

2.11

0.44

0.060

0.094

0

0.038

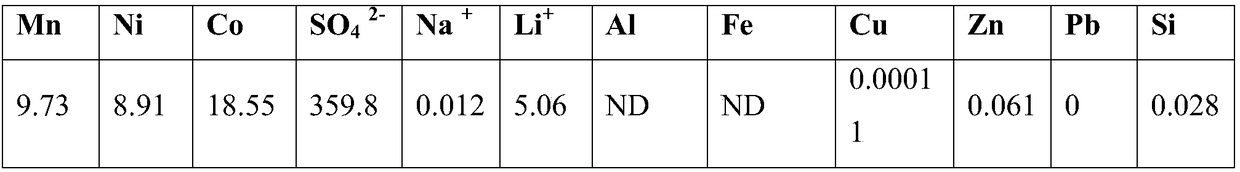

[0060] 2. See Table 5 for the composition of the pickling solution after removing other doping elements. Take 200mL of pickling solution after removing impurities, add 36.14gNiSO 4 .6H ...

Embodiment 3

[0069] A method for reclaiming and synthesizing a zinc-doped ternary material precursor by waste lithium batteries, comprising the following steps:

[0070] 1. See Table 7 for the composition of the acid immersion solution for the positive electrode material of the waste lithium battery. Use 5% NaOH solution to adjust the pH to 5, add iron powder with 4 times the Cu content and stir at 150rpm for 0.5h, then add 1.4 times the amount of hydrogen peroxide, the other doping elements can be removed by stirring the reaction at the same rate.

[0071] Table 7 (unit: g / L)

[0072] mn

Ni

co

SO 4 2-

Na +

Li +

Al

Fe

Cu

Zn

Pb

Si

12.92

14.36

23.08

366.4

0.038

5.33

2.11

0.44

0.060

0.094

0

0.038

[0073] 2. See Table 8 for the composition of the pickling solution after removing other doping elements. Take 200mL of pickling solution after removing impurities, add 8.41gNiSO 4 .6H 2 O, 6....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com