High-content ammonium glyhosate herbicide and preparation method thereof

A glyphosate ammonium salt and herbicide technology, applied in the field of pesticides, can solve the problems of serious foaming, insufficient yield, slow dissolution rate and the like, and achieve the effects of improving yield, good thermal stability and improving dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

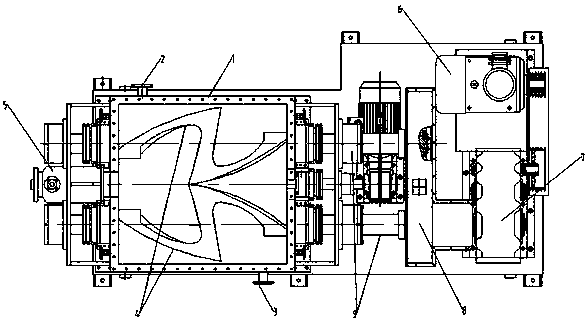

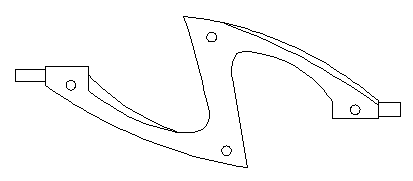

Image

Examples

Embodiment 1

[0033] Embodiment 1 A kind of high content glyphosate ammonium salt herbicide

[0034] Described herbicide comprises the raw material of following mass parts:

[0035] 80 parts of glyphosate, 9.25 parts of liquid ammonia, 8.5 parts of additives, 4.5 parts of ammonium sulfate;

[0036] Described liquefied ammonia, the purity of liquefied ammonia is 50%;

[0037] The ammonium sulfate, white crystals;

[0038] The auxiliary agent: includes the following components by weight: 3 parts of potassium tartrate, 1 part of copper sulfate, 0.5 parts of leucine, 2 parts of α-curcumene, 1 part of caffeic acid, and 1 part of fatty alcohol ether phosphate.

[0039] The preparation method of glyphosate ammonium herbicide:

[0040] Step 1 Input glyphosate and ammonium sulfate

[0041] According to the formula of herbicide, weigh glyphosate, liquid ammonia, ammonium sulfate;

[0042] Turn on the reactor to stir, the stirring rate is 600rpm, put glyphosate and ammonium sulfate into the react...

Embodiment 2

[0058] Embodiment 2 multivariate analysis experiment

[0059] Adopt the method of embodiment 1 to prepare herbicide, change the content of adjuvant component in the herbicide formula, meanwhile, change the following control parameters in the preparation method: change the drip rate of liquid ammonia in the step of dripping liquid ammonia, control in the heat preservation The intermediate control pH in the step, and the granulation time in the granulation molding step are carried out in Example 2-11, and the content of the auxiliary components used in Example 2-11 is shown in Table 1; The control parameters of are shown in Table 2;

[0060] The content of the auxiliary component that adopts in the embodiment 2-11 of table 1

[0061]

[0062] The control parameter that adopts in the embodiment 2-11 of table 2

[0063]

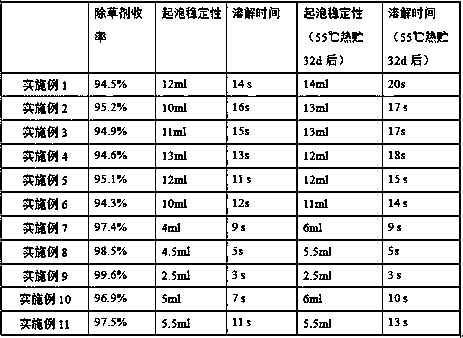

[0064] Adopt the method for embodiment 1-11 to prepare herbicide, herbicide is detected, specifically see Table 3;

[0065] Table 3 Test results of herb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com