Filter membrane component, manufacturing method and setting method thereof

A manufacturing method and membrane filtration technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of time required for washing, and achieve the effects of reducing washing time, preventing pollution, and preventing pressure rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

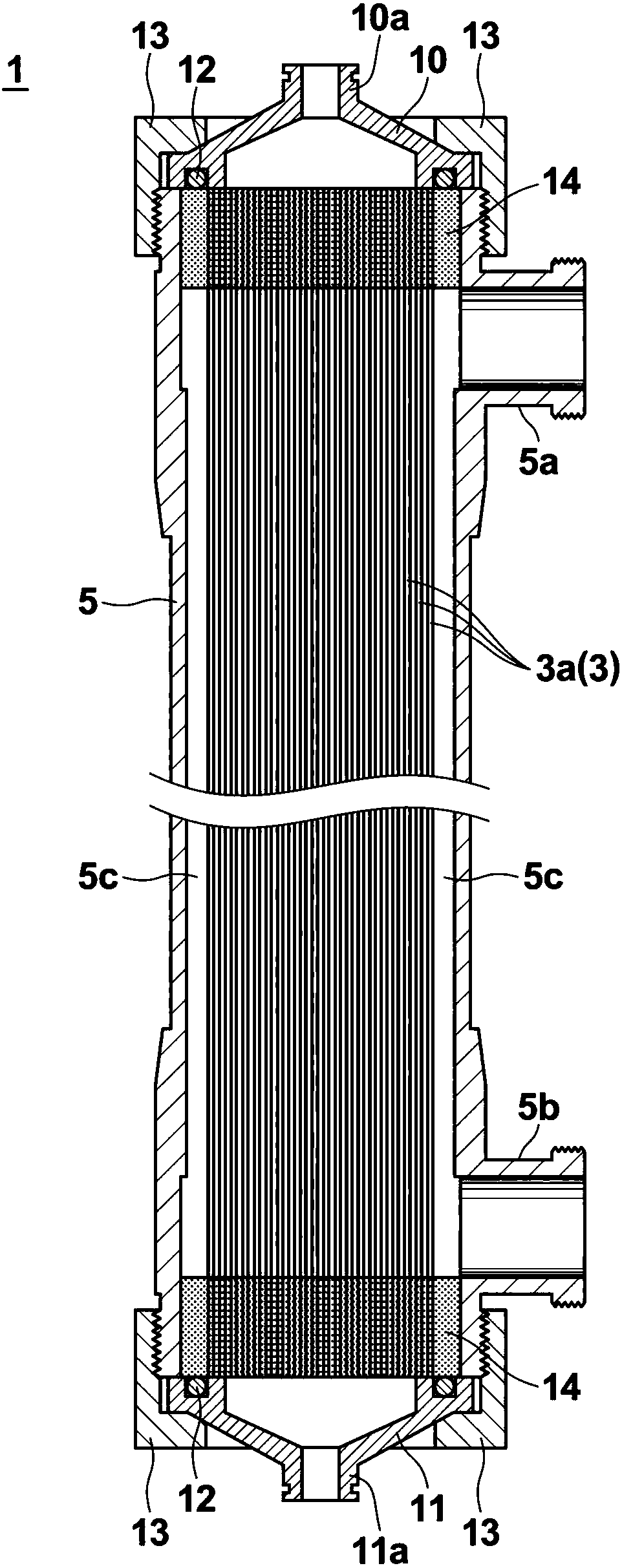

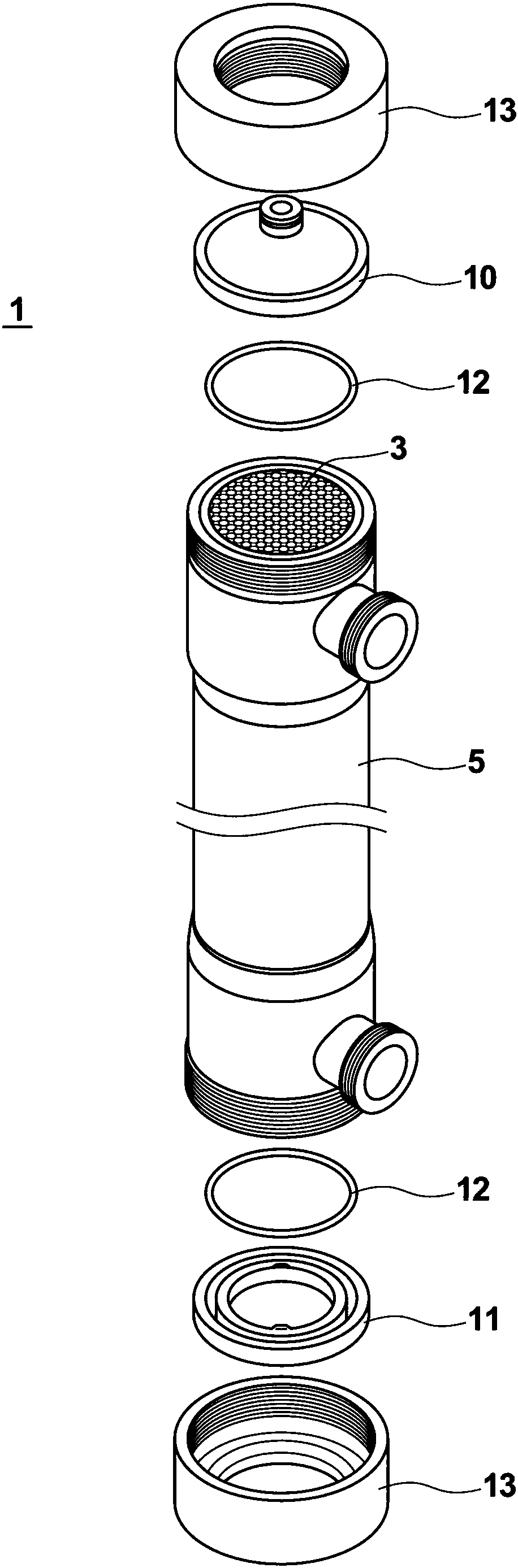

Embodiment 1

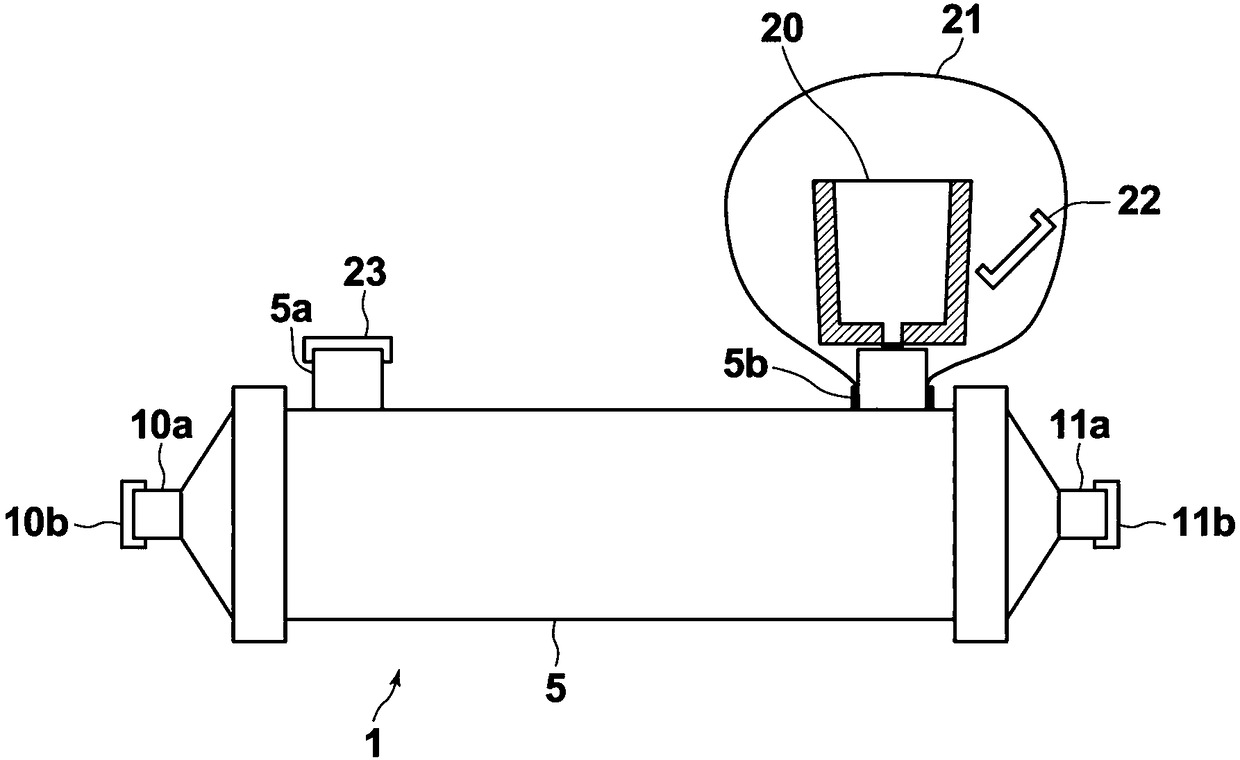

[0140] The pure water filtered by the ultrafiltration membrane is enclosed in the hollow fiber membrane module, and the hollow fiber membrane module is placed in an oven and heat-treated at 90°C for 16 hours to realize the state where the sterilized pure water is enclosed in the module. In this heat treatment, a bag made of polyethylene (PE) as a pressure buffering means and a cup made of polypropylene (PP) as a volume expansion absorbing means were attached to the nozzle on the raw water side. After completion of the heat treatment, the nozzle was sealed with a predetermined sealing member, and stored in a storage room adjusted to a temperature of 20° C. to 25° C. for 3 months.

[0141] After storage for 3 months, the pure water enclosed as a storage solution was sampled, and the number of viable bacteria in the storage solution was counted. In addition, the respective concentrations of TOC, metal ions, and chloride ions in the storage solution were measured simultaneously. ...

Embodiment 2、3

[0144] Except for changing the heating temperature and heating time to the conditions described in 1, it was carried out in the same manner as in Example 1, and the number of viable bacteria after heat treatment and storage, TOC in the storage solution, metal ions, and chloride ions were measured. their respective concentrations. The results are shown in Table 1. In Example 3, the viable count was 3 after storage for 3 months, but when ultrapure water was produced using each hollow fiber membrane module of this example, immediately after the start of operation, it was possible to obtain ultrapure water that could be used as ultrapure water. Water quality filtered water.

Embodiment 4、5、6

[0146] In the same manner as in Example 1, the number of viable cells after heat treatment and storage, the respective concentrations of TOC in the storage solution, metal ions, and chloride ions were measured. The results are shown in Table 1. When producing ultrapure water using each of the hollow fiber membrane modules of this example, filtered water of water quality usable as ultrapure water was obtained immediately after the start of operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com