Preparation method of NCM ternary cathode material doped with Al<3+> on surface

A positive electrode material and surface layer technology, applied in the field of chemical energy storage batteries, can solve problems such as poor electrochemical performance, and achieve the effects of improving reversible discharge capacity, inhibiting mixed discharge, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

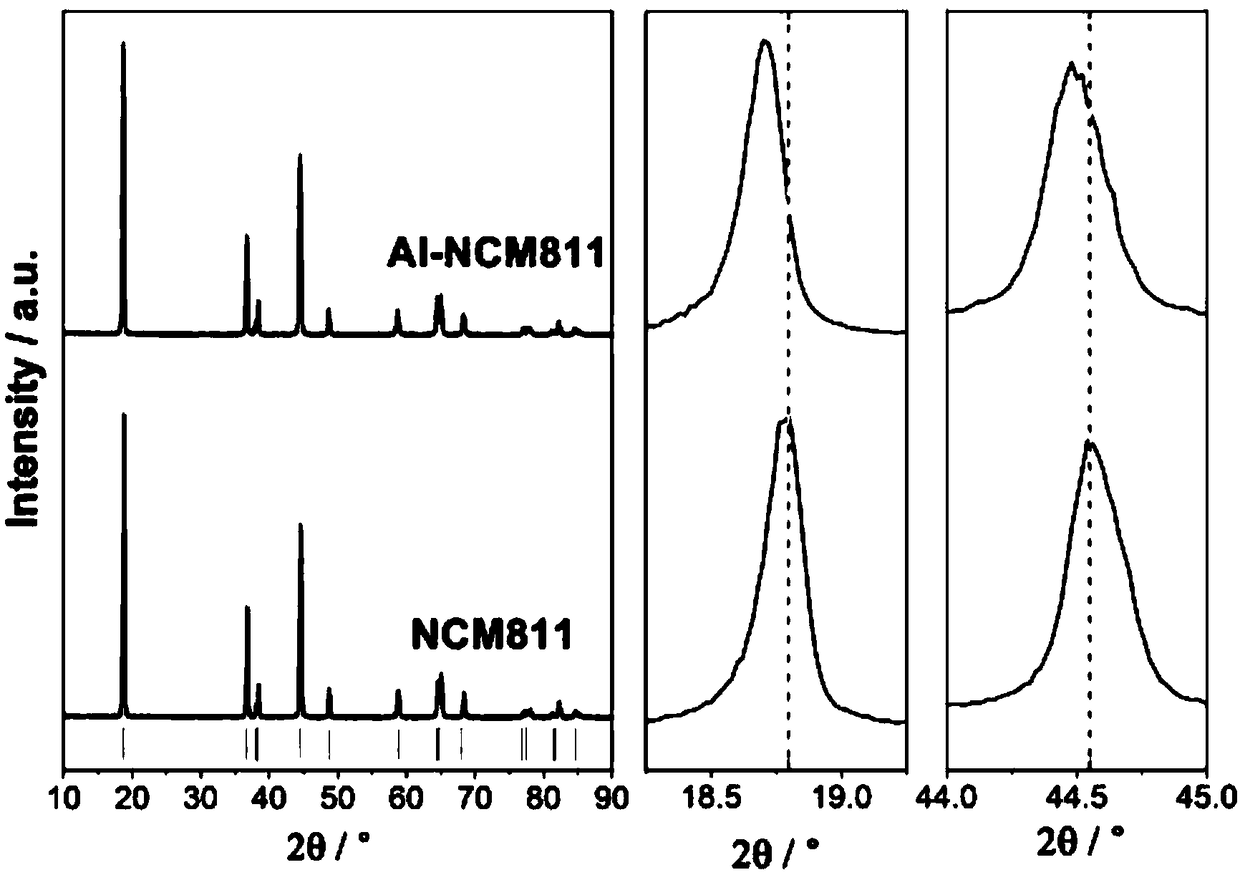

[0034] LiOH·H 2 O was added into the mortar, and after dry grinding for 15 min, it was mixed with Al(NO 3 ) 3 9H 2 O was sonicated in ethanol for 4 h, then transferred to a mortar and Ni 0.8 co 0.1 mn 0.1 (OH) 2 Powder, after dry milling for 25 minutes, add ethanol and continue grinding for 25 minutes, then place the mixture of the three in an oxygen atmosphere, heat it to 450°C and keep it for 6 hours, then raise the temperature to 750°C and keep it for 12 hours, then cool with the furnace. get doped Al 3+ The NCM ternary cathode material Li 0.99 al 0.01 [Ni 08 co 0.1 mn 0.1 ]O 2 , abbreviated as Al-NCM811; among them, LiOH·H 2 O and Al(NO 3 ) 3 9H 2 The molar ratio of O is 99:1, LiOH·H 2 O and Ni 0.8 co 0.1 mn 0.1 (OH) 2 The molar ratio is 1.040:1.

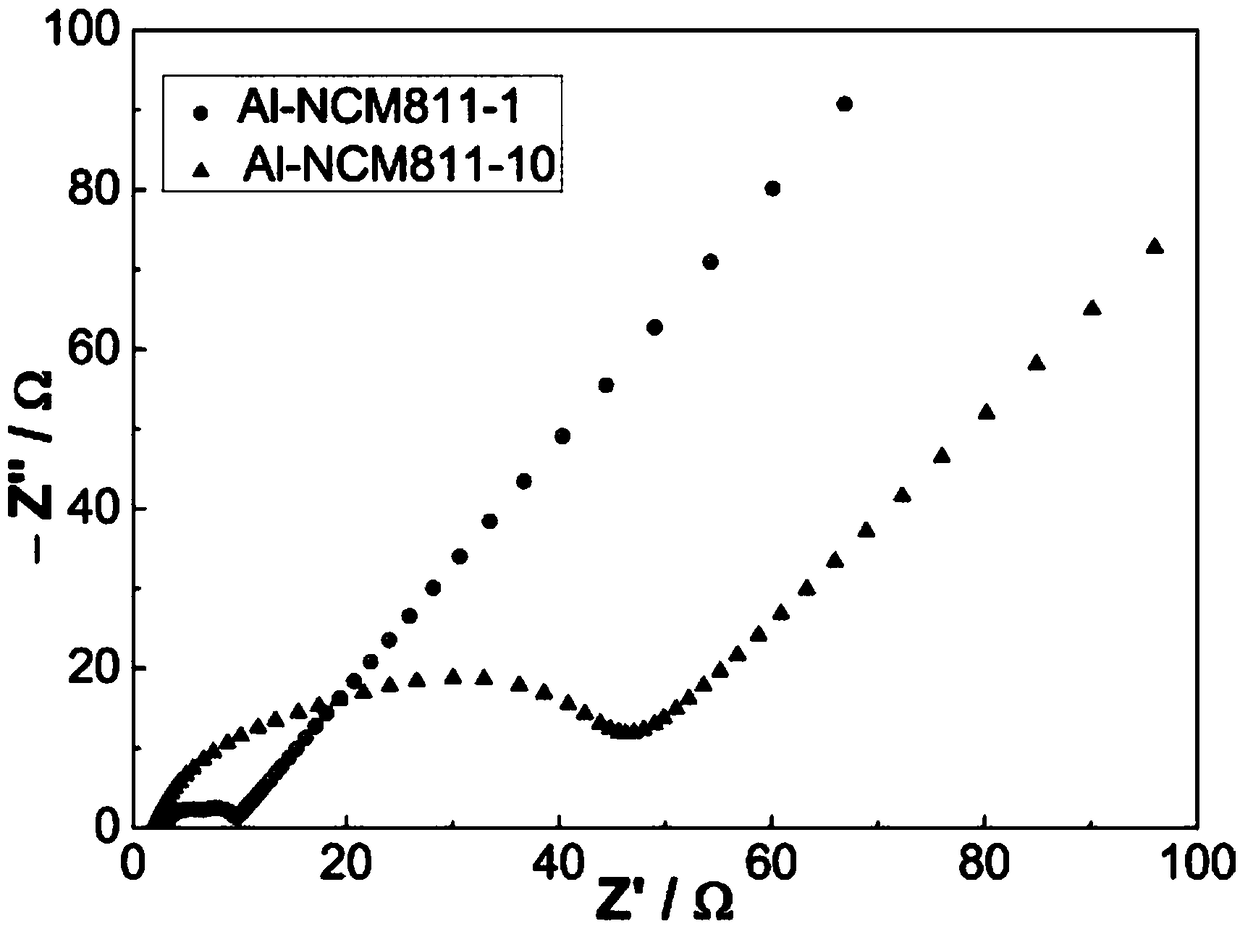

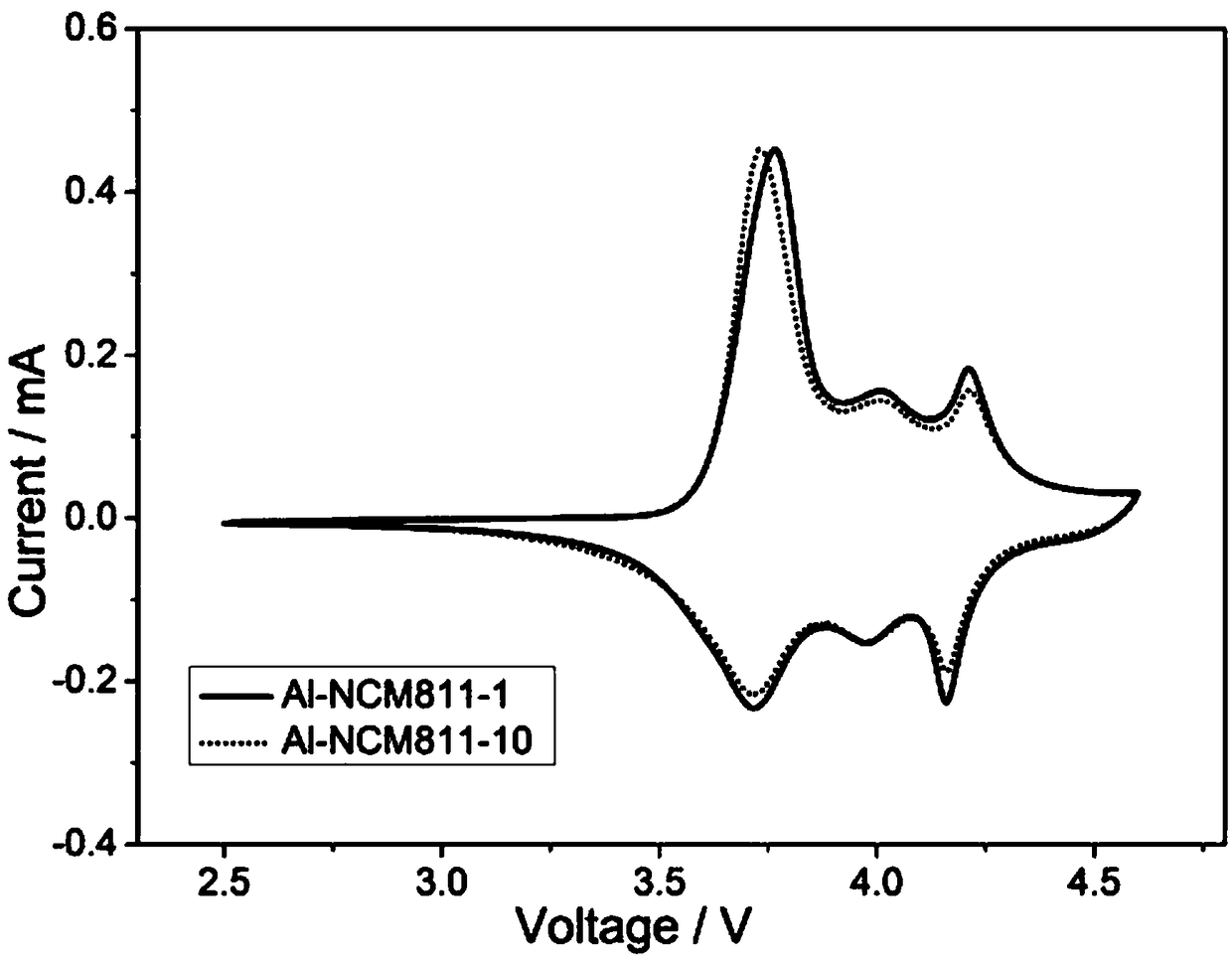

[0035] The Al-NCM811 prepared in Example 1 was used as the positive electrode material to assemble a CR2025 button battery, and the corresponding electrochemical performance tests were carried out.

[0036...

Embodiment 2

[0045] LiOH·H 2 O was added into the mortar, and after dry grinding for 15 min, it was mixed with Al(NO 3 ) 3 9H 2 O was sonicated in ethanol for 4 h, then transferred to a mortar and Ni 0.8 co 0.1 mn 0.1 (OH) 2 Powder, after dry milling for 25 minutes, add ethanol and continue grinding for 25 minutes, then place the mixture of the three in an oxygen atmosphere, heat it to 450°C and keep it for 6 hours, then raise the temperature to 750°C and keep it for 12 hours, then cool with the furnace. get doped Al 3+ The NCM ternary cathode material Li 0.995 al 0.005 [Ni 08 co 0.1 mn 0.1 ]O 2 , abbreviated as Al-NCM811; among them, LiOH·H 2 O and Al(NO 3 ) 3 9H 2 The molar ratio of O is 199:1, LiOH·H 2 O and Ni 0.8 co 0.1 mn 0.1 (OH) 2 The molar ratio is 1.045:1.

[0046] The Al-NCM811 prepared in embodiment 2 is assembled into CR2025 button battery as positive electrode material and carries out electrochemical performance test. The constant current charge and dis...

Embodiment 3

[0048] LiOH·H 2 O was added into the mortar, and after dry grinding for 15 min, it was mixed with Al(NO 3 ) 3 9H 2 The O powder was sonicated in ethanol for 4 h, then transferred to a mortar, and Ni 0.8 co 0.1 mn 0.1 (OH) 2 Powder, after dry milling for 25 minutes, add ethanol and continue grinding for 25 minutes, then put the mixture of the three in an oxygen atmosphere, first heat to 450°C and keep it for 6 hours, then raise the temperature to 750°C and keep it for 12 hours, then cool with the furnace, get doped Al 3+ The NCM ternary cathode material Li 0.985 al 0.015 [Ni 08 co 0.1 mn 0.1 ]O 2 , abbreviated as Al-NCM811; among them, LiOH·H 2 O and Al(NO 3 ) 3 9H 2 The molar ratio of O is 65.7:1, LiOH·H 2 O and Ni 0.8 co 0.1 mn 0.1 (OH) 2 The molar ratio is 1.034:1.

[0049] The Al-NCM811 prepared in embodiment 3 is assembled into CR2025 button cell as positive electrode material and carries out electrochemical performance test. The constant current cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com