Composition of photoluminescence bubble water

A technology of photoluminescence and bubble water, applied in luminescent materials, nano optics, toys, etc., can solve the problems of dissolved oxygen fluorescence quenching, inability to add bubble water, weak fluorescence, etc., and achieve high photostability and wide absorption Effect of peak, broad Stokes shift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

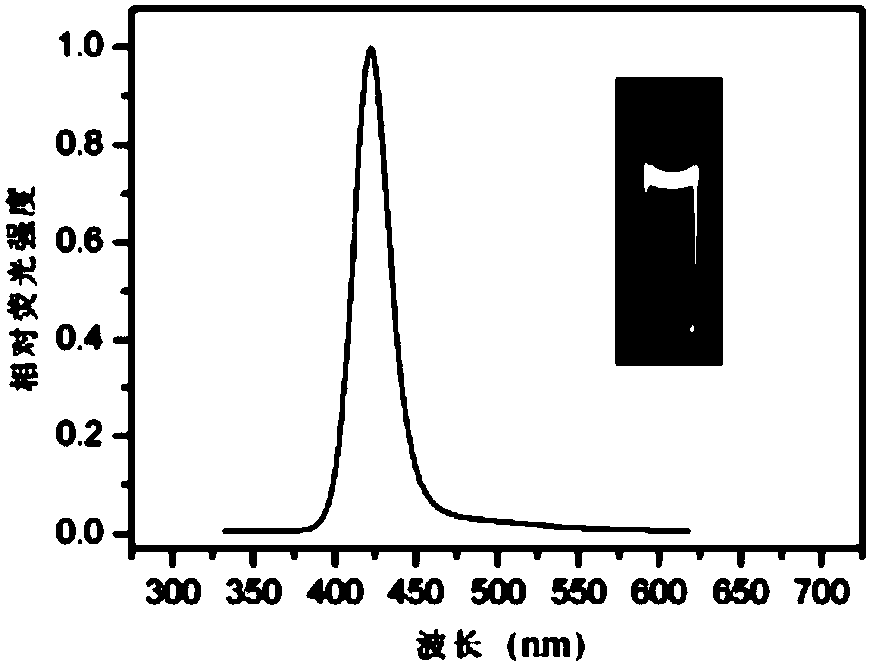

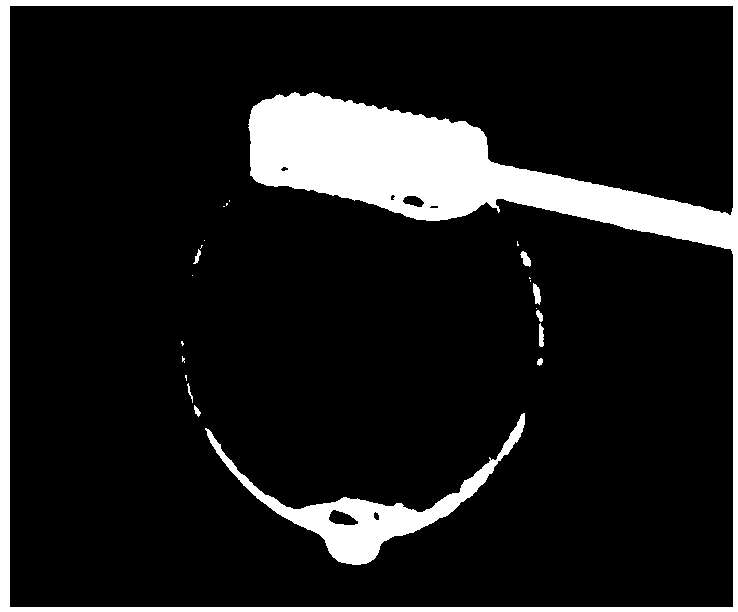

Embodiment 1

[0021] In the present embodiment, the surfactant is sodium lauryl sulfate and fatty alcohol polyoxyethylene ether-9; the humectant is glycerin; the preservative is Kathon, and according to the weight percentage, each component is as follows : Water: 87.89%; Zinc Acetate: 0.1%; Sodium Polyphosphate: 0.5%; Mercaptosuccinic Acid: 0.01%; Sodium Sulfide: 0.2%; Sodium Lauryl Sulfate: 2%; %: 4; Coconut Oil Diethanolamide: 2%; Glycerol: 3%; Cathone: 0.3%.

[0022] Dissolve 0.1g of zinc acetate in ultrapure water, add 0.5g of sodium polyphosphate under rapid stirring, then use sodium hydroxide solution to control the pH value to 8-9, add 0.01g of mercaptosuccinic acid, and pass N2 under vigorous stirring to remove Oxygen for 30min, and finally 10ml of 2% sodium sulfide aqueous solution was dripped at a rate of 0.5mL / min. After the dropwise addition, continue to stir for 24 hours to obtain a solution containing zinc sulfide quantum dots. Add 2g sodium lauryl sulfate, 4g fatty alcohol ...

Embodiment 2

[0025] In this embodiment, the metal salt is copper chloride; the surfactant is sodium dodecyl sulfonate, nonylphenol ethoxylate-10 and cocamidopropyl betaine; the humectant is propylene glycol; the preservative It is ethyl p-hydroxybenzoate, and according to weight percentage, each component is as follows: water: 88.359%; zinc acetate: 0.3%; copper chloride: 0.011%; sodium polyphosphate: 0.8%; mercaptosuccinic acid: 0.03% %; Sodium Sulfide: 0.4%; Sodium Lauryl Sulfonate: 2%; Nonylphenol Ethoxylate-10: 2%; Cocamidopropyl Betaine: 1%; Propylene Glycol: 5%; Ethyl Benzoate 0.1%.

[0026] Dissolve 0.3g of zinc acetate and 0.011l of copper chloride in ultrapure water, add 0.8g of sodium polyphosphate under rapid stirring, then use sodium hydroxide solution to control the pH value to 8-9, add 0.03g of mercaptosuccinic acid, and vigorously Under stirring, pass N2 to remove oxygen for 30 minutes, and finally add 20ml of 2% sodium sulfide aqueous solution dropwise at a rate of 0.5mL / m...

Embodiment 3

[0029] In the present embodiment, the metal salt is manganese acetate; the surfactant is sodium fatty alcohol polyoxyethylene ether sulfate, octylphenol polyoxyethylene ether-10 and disodium lauroamphodiacetate; the humectant is sorbitol; The preservative is sodium benzoate, and according to the percentage by weight, the components are as follows: water: 92.83%; zinc acetate: 0.5%; manganese acetate: 0.047%; sodium polyphosphate: 1.5%; mercaptosuccinic acid: 0.05%; Sodium: 0.6%; Sodium Alcohol Ether Sulfate: 1%; Octylphenol Ethoxylate-10: 1%; Disodium Lauroamphodiacetate: 1%; Sorbitol: 1%; Sodium Benzoate : 0.5%.

[0030] Dissolve 0.5g of zinc acetate and 0.047g of manganese acetate in ultrapure water, add 1.5g of sodium polyphosphate under rapid stirring, then use sodium hydroxide solution to control the pH value to 8-9, add 0.05g of mercaptosuccinic acid, and stir vigorously Pass N2 down to remove oxygen for 30 minutes, and finally add 30ml of 2% sodium sulfide aqueous solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com