Preparation method of composite carrier catalyst and low-carbon chain olefin

A composite carrier and catalyst technology, applied in the direction of carbon compound catalysts, catalysts, molecular sieve catalysts, etc., can solve the problems of catalyst deactivation, difficult treatment, and blockage of catalyst pores, and achieve high selectivity, low cost, and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] A method for preparing a composite carrier catalyst disclosed in an embodiment of the present invention includes:

[0041] Step 1 prepares the SAPO-34 molecular sieve carrier with multi-level channels:

[0042] Step 11 prepares initial gel mixture;

[0043] Step 12: Perform crystallization treatment on the initial gel mixture, pass a mixed gas of acetylene and hydrogen during the crystallization treatment process, and repeatedly inflate and deflate the gas, and press to a predetermined pressure to obtain SAPO-34 molecular sieve raw powder ;

[0044] In step 13, the SAPO-34 molecular sieve raw powder is roasted to obtain a SAPO-34 molecular sieve carrier, wherein the roasting can be carried out in a muffle furnace, and the preferred roasting temperature is 500-550° C., and the roasting time is 6-10 hours. The heating rate is less than or equal to 5°C / min. When the calcination temperature is lower than 500°C, the removal of the template agent is incomplete. When the tem...

Embodiment 1

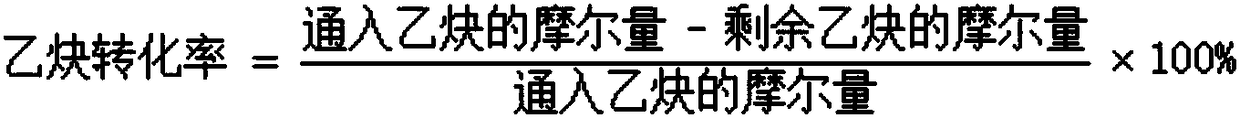

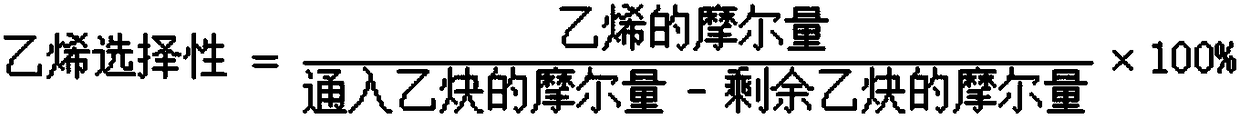

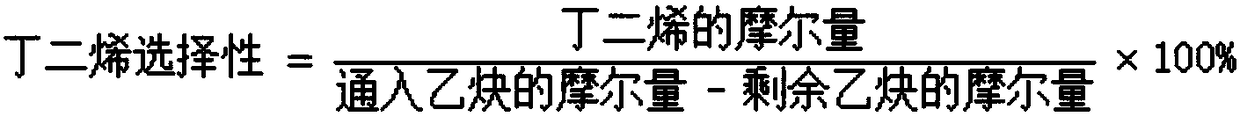

[0064] This embodiment discloses a method for preparing a composite carrier catalyst and a method for preparing a low-carbon chain system using the composite carrier catalyst. The composite carrier catalyst includes a composite carrier and an active component. The composite support includes hierarchically porous SAPO-34 and nano α-Al 2 o 3 Composite after treatment, the active components are Pd, Cu and K. The carrier compounding adopts a mechanical ball milling method, the preparation method of the catalyst adopts equal-volume impregnation, and the composite carrier catalyst is obtained after impregnation and roasting. Using the composite carrier catalyst prepared in this example, under certain conditions, hydrogen and acetylene are used to react in a fluidized bed to prepare low-carbon alkenes, especially ethylene and butadiene products.

[0065] Among them, in the composite supported catalyst, α-Al 2 o 3 The ratio of the mass fraction of SAPO-34 to the multi-stage channe...

Embodiment 2

[0082] The difference from Example 1 is that in the step (3), the volume ratio of acetylene and hydrogen is 1:5; in the step (10), the volume ratio of acetylene and hydrogen is 1:5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com