NBR-PVC (nitrile butadiene rubber-polyvinyl chloride) blended rubber-plastic alloy material, preparation method and application

A rubber-plastic alloy and blending technology, which is applied in the field of NBR-PVC blended rubber-plastic alloy materials and its preparation and application, can solve the problems of difficult small-batch multi-variety production, large equipment investment, and high overall cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5、 comparative example 1~2

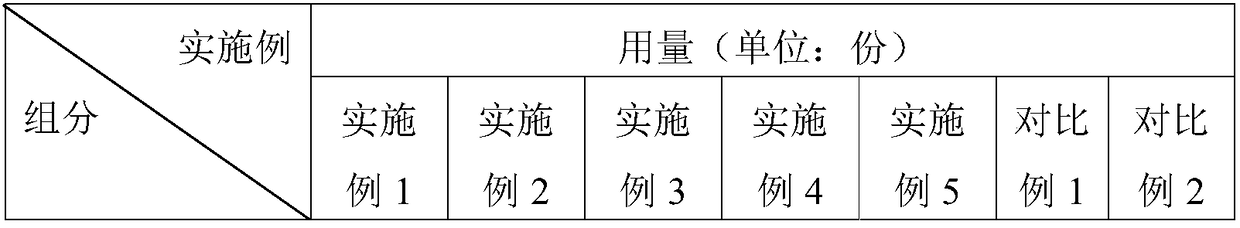

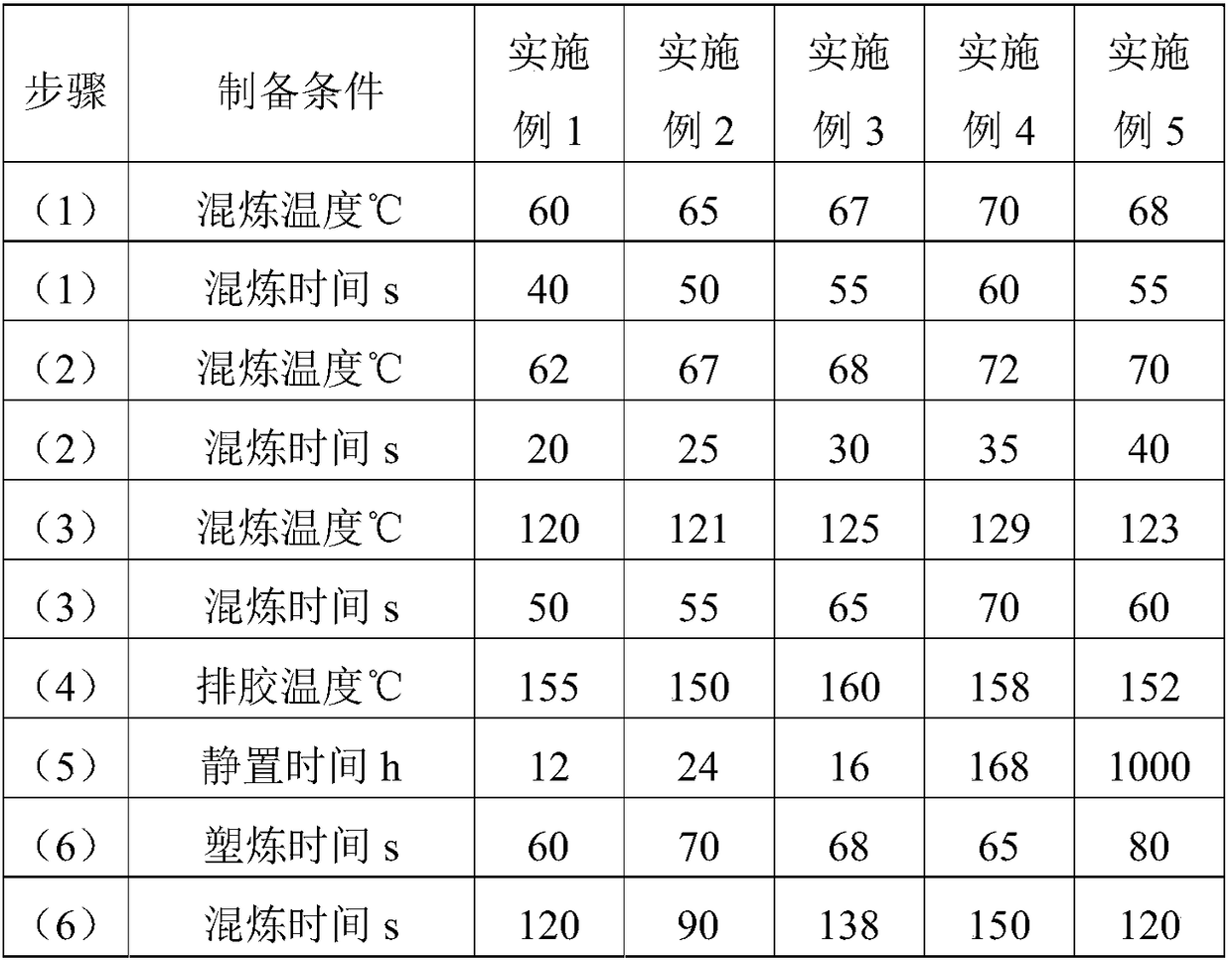

[0087] Table 1

[0088]

[0089]

[0090] "-" in Table 1 indicates that the dosage is "0".

Embodiment 1~5

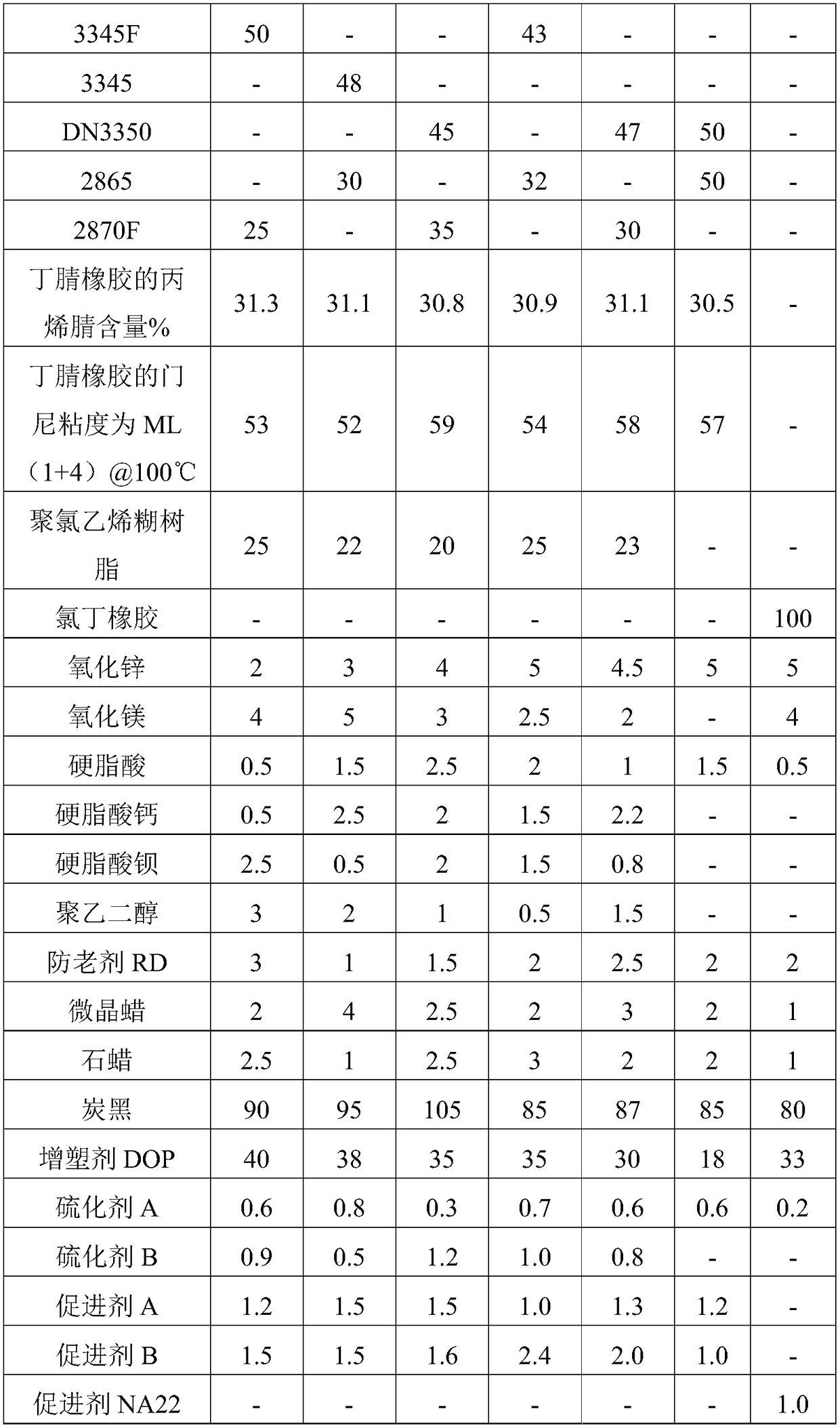

[0092] Embodiments 1 to 5, the raw material components of each embodiment in Table 1 are obtained according to the following preparation steps to obtain the product of each embodiment (the parameters of each step are as shown in Table 2):

[0093] (1) In a banbury mixer, nitrile rubber A and nitrile rubber B rubber are mixed to obtain mixture A;

[0094] (2) Mix mixture A, activator zinc oxide, magnesium oxide, stearic acid, calcium stearate, barium stearate, polyethylene glycol, 2,2,4-trimethyl- Mixing 1,2-dihydroquinoline polymer, microcrystalline wax and paraffin wax to obtain mixture B;

[0095] (3) In an internal mixer, mix mixture B and 1 / 2 of the amount of carbon black to obtain mixture C;

[0096] (4) In the internal mixer, mix mixture C, 1 / 2 of the amount of carbon black, polyvinyl chloride paste resin, plasticizer, carry out glue removal in the internal mixer, and discharge the sheet in the open mixer ( Carry out in open mill, wheelbase 3mm), get rubber premixed gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com