Functional calcium carbonate with modified surface activity and preparation method of functional calcium carbonate

A surface-active, calcium carbonate technology, used in chemical instruments and methods, dyed organosilicon compound treatment, inorganic pigment treatment, etc., can solve the problems of difficult processing, poor stability, low organic polymer strength, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

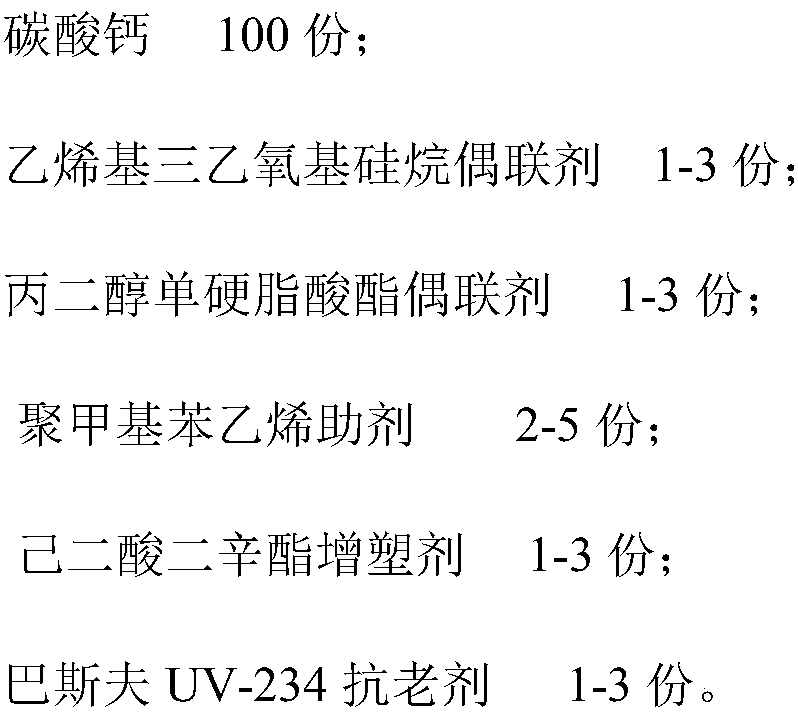

[0019] The present embodiment is made of the following raw materials by weight:

[0020]

[0021] Described calcium carbonate is 500 purpose calcium carbonate powder;

[0022] The content of the boric acid polyol ester coupling agent is 40%;

[0023] The specific technical scheme of the preparation method of functional calcium carbonate is as follows:

[0024] (1) Take 100g of 500 mesh calcium carbonate powder, add water and stir, and configure it into a 20% calcium carbonate aqueous emulsion solution;

[0025] (2) In the above calcium carbonate aqueous emulsion solution system, add 1g of vinyl triethoxysilane coupling agent, 1g of propylene glycol monostearate coupling agent, 2g of polymethylstyrene auxiliary, 1g of hexamethylene Dioctyl dioate plasticizer, continue to stir evenly;

[0026] (3) Control the temperature of the system at 50°C and stir for 1h;

[0027] (4) Finally, add 1 g of BASF UV-234 antioxidant, and stir at 60 °C for 1 h;

[0028] ⑸ After the reactio...

Embodiment 2

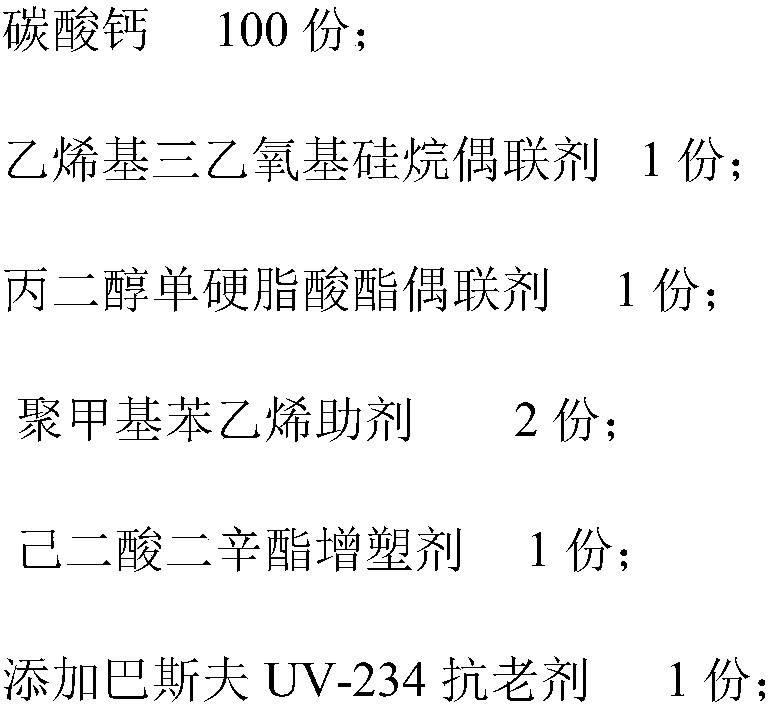

[0030] The present embodiment is made of the following raw materials by weight:

[0031]

[0032] Described calcium carbonate is 600 purpose calcium carbonate powder;

[0033] The content of the boric acid polyol ester coupling agent is 50%;

[0034] The specific technical scheme of the preparation method of functional calcium carbonate is as follows:

[0035] (1) Pour 10kg of 600 mesh calcium carbonate powder into a heating and stirring device, add water and stir, and configure it into a 25% calcium carbonate aqueous emulsion solution;

[0036] (2) In the above calcium carbonate aqueous emulsion solution system, add 0.15kg of vinyl triethoxysilane coupling agent, 0.15kg of propylene glycol monostearate coupling agent, 0.3kg of polymethylstyrene auxiliary, 0.2 kg of dioctyl adipate plasticizer, continue to stir evenly;

[0037] (3) Control the temperature of the system to 55°C and stir for 1.5h;

[0038] (4) Finally, add 0.2kg of BASF UV-234 anti-aging agent, and stir a...

Embodiment 3

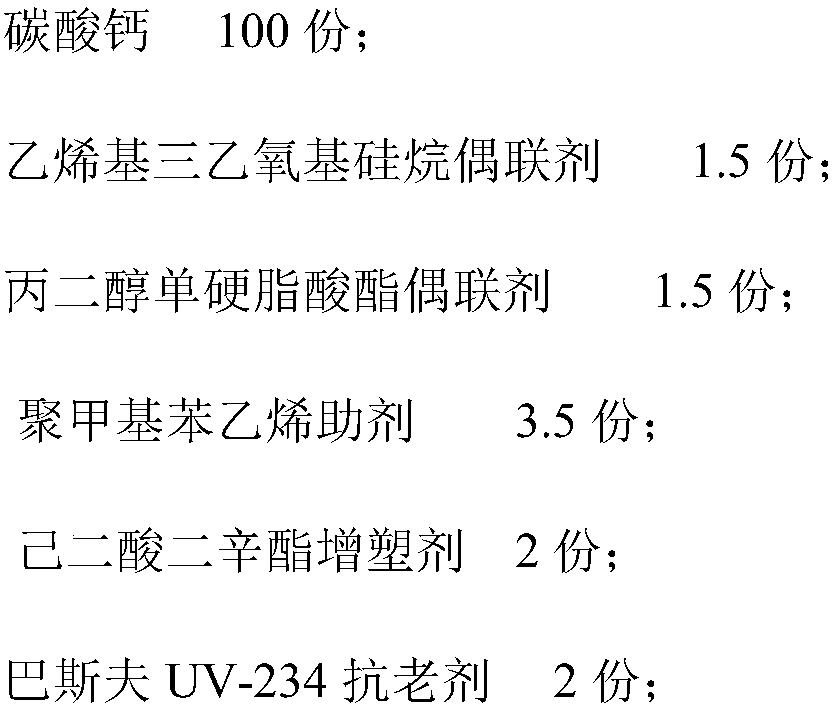

[0041] The present embodiment is made of the following raw materials by weight:

[0042]

[0043] Described calcium carbonate is 800 purpose calcium carbonate powder;

[0044] The content of the boric acid polyol ester coupling agent is 60%;

[0045] The specific technical scheme of the preparation method of functional calcium carbonate is as follows:

[0046] (1) Pour 100kg of 800-mesh calcium carbonate powder into the heating mixer, add water and stir evenly, and configure it into a 30% calcium carbonate aqueous emulsion solution;

[0047] (2) In the above-mentioned calcium carbonate aqueous emulsion solution system, add 3kg vinyl triethoxysilane coupling agent, 3kg propylene glycol monostearate coupling agent, 5kg polymethylstyrene auxiliary, 3kg hexanediol. dioctyl acid plasticizer, continue to stir evenly;

[0048] (3) Control the temperature of the system to 60°C and stir for 2h;

[0049] (4) Finally, add 3kg of BASF UV-234 antioxidant, and stir at 70°C for 2 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com