Hard-seal ball valve with high wear resistance and corrosion resistance and preparation method

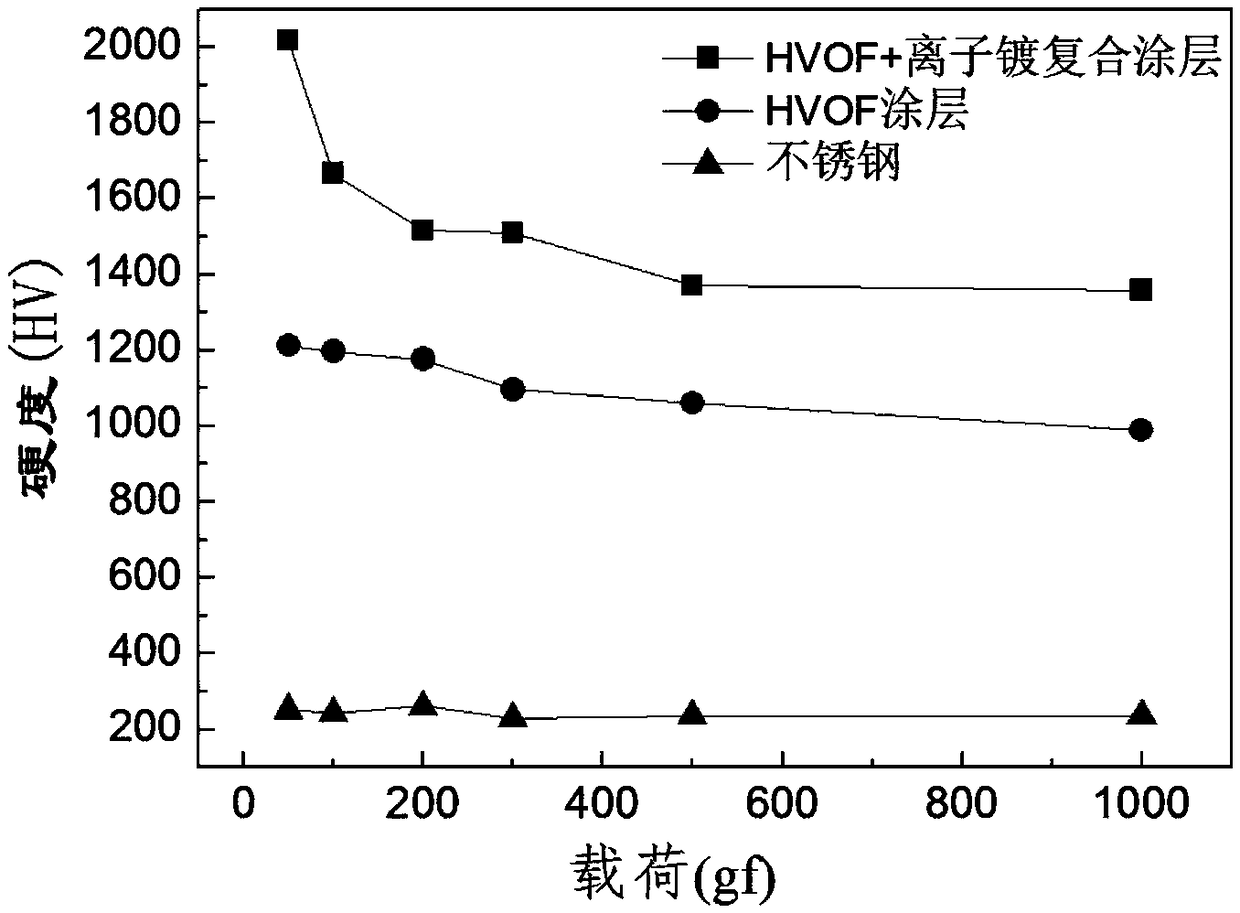

A kind of hard sealing, high wear resistance technology, applied in the field of metal surface engineering, can solve the problems of high temperature resistance sealing layer, easy to be damaged, affecting the compactness of the coating, etc., to achieve excellent corrosion resistance, excellent corrosion resistance, The effect of a low coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025]Example 1: Put the polished stainless steel ball and valve seat in an ultrasonic cleaning machine, first remove oil and wax in acetone at 25°C, and then remove residual acetone in alcohol at 25°C, and finally use the water temperature as Wash with deionized water at 20-30°C, dehydrate and then dry. Then, the ball and the valve seat are sandblasted, and the sandblasting material is brown corundum sand. Use a spray gun to spray the ball and valve seat after sandblasting. The spray powder is WC-12Co, the spray distance is 330mm, the flow rate of oxygen is 50L / h, and the flow rate of kerosene is 30L / h. Grind and polish the sprayed layer with No. 120-1200 sandpaper in sequence to a roughness of Ra0.5 μm, then place it in an ultrasonic cleaner, clean it in alcohol at 25° C., and then dry it. Fix the dried ball and valve seat on the inner turret of the vacuum ion coating machine, and vacuumize to 3.0×10 -4 After Pa, start the turret to make the rotation speed 3r / min until the...

Embodiment 2

[0026] Example 2: Put the polished carbon steel ball and valve seat in an ultrasonic cleaning machine, first remove oil and wax in acetone at 25°C, then remove residual acetone in alcohol at 25°C, and finally use water temperature Wash with deionized water at 20-30°C, dehydrate and then dry. Then, the ball and the valve seat are sandblasted, and the sandblasting material is brown corundum sand. Use a spray gun to spray the ball and valve seat after sandblasting, and the spray powder is Cr 3 C 2 -NiCr, the spraying distance is 380mm, the flow rate of oxygen is 60L / h, and the flow rate of kerosene is 30L / h. Use No. 120-1200 sandpaper to polish the surface of the sprayed coating in sequence, then place it in an ultrasonic cleaner, wash it in alcohol at 25°C, and then dry it. Fix the dried ball and valve seat on the inner turret of the vacuum ion coating machine, and vacuumize to 3.0×10 -4 After Pa, start the turret to make the rotation speed 3r / min until the coating is finish...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com