Composite catalyst carrier for fuel cell, and preparation method and application thereof

A composite catalyst, fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of limited specific surface area, single structure, insufficient protection of catalyst active components, etc., to achieve high electronic conductivity, high application value, The effect of ensuring the activity and catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

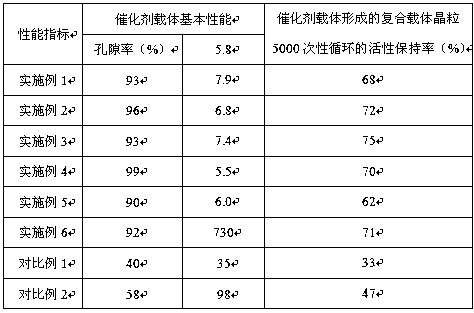

Examples

Embodiment 1

[0031] The preparation of composite catalyst carrier for fuel cell, the steps are as follows:

[0032] a. Using 0.3g of polystyrene microspheres as a template, add 60mL of isopropanol, stir at 250r / min, add 2g of silicon source, the silicon source is hexamethyldisiloxane, adjust the pH of the solution to 10 with ammonia water, Centrifuge at high speed, take the precipitate, wash 3 to 5 times with water, and obtain polystyrene / SiO 2 Composite microspheres;

[0033] b. To the polystyrene / SiO prepared in step a 2 Add 50mL, 30wt% ethanol to the composite microspheres, ultrasonically disperse for 20min, add 2g of surfactant and 10g of titanium source, the surfactant is polyvinylpyrrolidone; the titanium source is titanium tetrachloride; heat in a water bath at 70°C for 3h, Centrifuge, take the precipitate, wash 3 to 5 times with water, and dry in vacuum at 60°C for 12 hours to obtain polystyrene / SiO 2 / TiO 2 Composite microspheres;

[0034] c, the polystyrene / SiO obtained in s...

Embodiment 2

[0037] The preparation of composite catalyst carrier for fuel cell, the steps are as follows:

[0038] a. Take 0.5g polystyrene microspheres as a template, add 90mL of isopropanol, stir at 300r / min, add 5g of silicon source, the silicon source is ethyl orthosilicate, methyl orthosilicate, adjust the pH of the solution with ammonia water value to 10, centrifuge, take the precipitate, wash 3 to 5 times with water, and obtain polystyrene / SiO 2 Composite microspheres;

[0039] b. To the polystyrene / SiO prepared in step a 2 Add 60mL, 35wt% ethanol to the composite microspheres, ultrasonically disperse for 20min, add 2g surfactant and 20g titanium source, the surfactant is sodium dodecylbenzenesulfonate; the titanium source is tetrabutyl titanate; 80 Heating in a water bath at ℃ for 1 hour, centrifuging, taking the precipitate, washing with water 3 to 5 times, and drying in vacuum at 60 ℃ for 10 hours to obtain polystyrene / SiO 2 / TiO 2 Composite microspheres;

[0040] c, the po...

Embodiment 3

[0043] The preparation of composite catalyst carrier for fuel cell, the steps are as follows:

[0044] a. Take 0.4g polystyrene microspheres as template, add 60mL isopropanol, stir at 240r / min, add 4g silicon source, silicon source is trimethylethoxysilane, methyltrimethylsilane, use ammonia water Adjust the pH value of the solution to 10, centrifuge, take the precipitate, wash 3 to 5 times with water, and obtain polystyrene / SiO 2 Composite microspheres;

[0045] b. To the polystyrene / SiO prepared in step a 2 Add 55mL, 34wt% ethanol to the composite microspheres, ultrasonically disperse for 20min, add 2g surfactant and 15g titanium source, the surfactant is fatty acid glyceride; the titanium source is tetrabutyl titanate; heat in a water bath at 78°C 2h, centrifuge, take the precipitate, wash 3-5 times with water, and dry in vacuum at 60°C for 11h to obtain polystyrene / SiO 2 / TiO 2 Composite microspheres;

[0046] c, the polystyrene / SiO obtained in step b 2 / TiO 2 Mix t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com