Decorative film, method for producing same, and decorated molded article

A manufacturing method and decorative film technology, which can be used in decorations, wood layered products, chemical instruments and methods, etc., can solve problems such as difficult design, and achieve high versatility, excellent wear resistance, and excellent formability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0220] Hereinafter, the present invention will be described in detail through examples, but the present invention is not limited to the following examples. In addition, in an Example, a part means a mass part, % means a mass % (except the % in elongation).

Synthetic example A-1

[0221] Synthesis Example A-1 "Acrylic Copolymer A-1 Solution"

[0222] 150 parts of methyl isobutyl ketone (MIBK) was charged into a four-necked flask equipped with a cooling tube, a stirring device, a thermometer, and a nitrogen gas introduction tube, and the temperature was raised while stirring under a nitrogen atmosphere. After the temperature in the flask reached 74°C, the temperature was maintained as the synthesis temperature, and 3 parts of methyl methacrylate, 82.54 parts of n-butyl methacrylate, 12.85 parts of acrylate-4- Hydroxybutyl ester, 0.61 part of methacrylic acid, 1 part of Fancryl FA-711MM (manufactured by Hitachi Chemical Co., Ltd., pentamethylpiperidinyl methacrylate), and 0.1 part of azobisisobutyronitrile Mixed monomer solution. 0.02 parts of azobisisobutyronitrile was gradually added every 1 hour after 1 hour after completion|finish of monomer addition, and reaction was continued until the unreacted monomer in a solution became 1% or less. After the u...

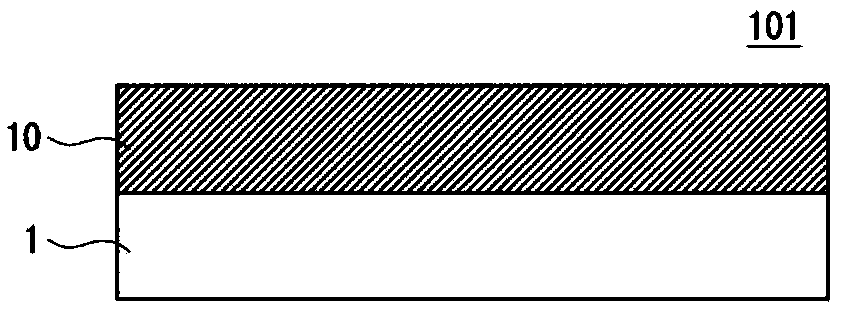

Embodiment 101

[0298] Using a doctor blade, the coating material for hard coating (HC-1) was coated on a sheet of a polycarbonate-based substrate (Makrofol, DE1-1 manufactured by Bayer) with a thickness of 300 μm and an A4 size. The surface was dried in an oven at 100° C. for 1 minute to evaporate the solvents. The doctor blade was selected so that the film thickness after drying would be 20 μm.

[0299] Then, it was left to stand in a constant temperature room at 50° C. for 4 days to allow the reaction (aging) of the acrylic copolymer and the polyisocyanate compound to progress, and to form a hard coat layer on the polycarbonate base material to obtain a decorative film.

[0300] The decorative film was evaluated for adhesiveness, solvent resistance, pencil hardness, abrasion resistance, moldability, sunscreen resistance, and weather resistance according to the method described later, and the results are shown in Table 8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com