Preparation method of sodium sulfide reaction precursor in polyphenylene sulfide production

A technology of polyphenylene sulfide and sodium sulfide, applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., can solve the problems of inability to guarantee the quality of polyphenylene sulfide products, unfavorable polycondensation reaction, large energy consumption, etc., and achieves remarkable results. Economic and environmental protection value, beneficial to promotion, simple implementation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

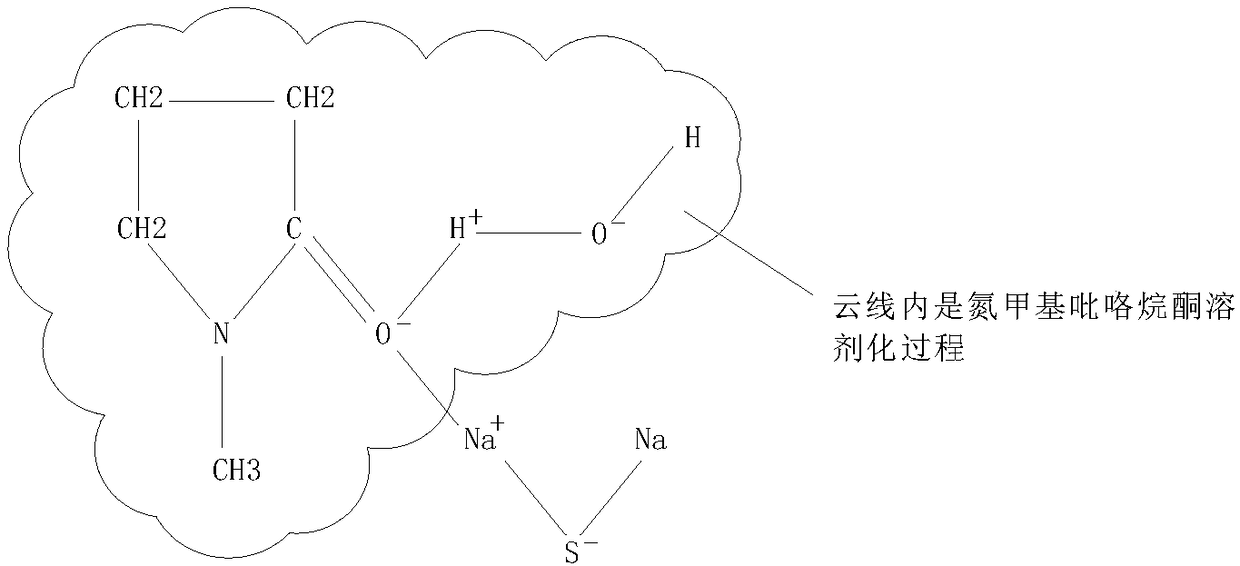

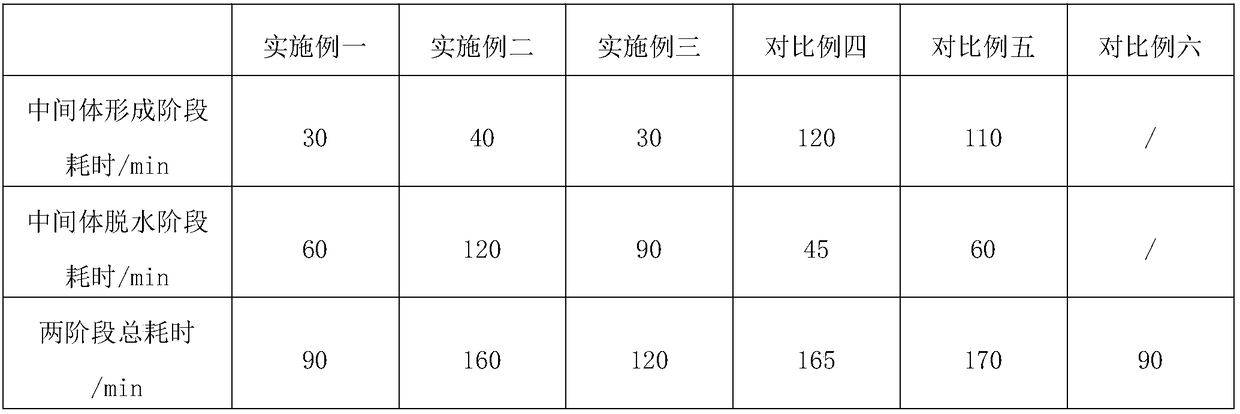

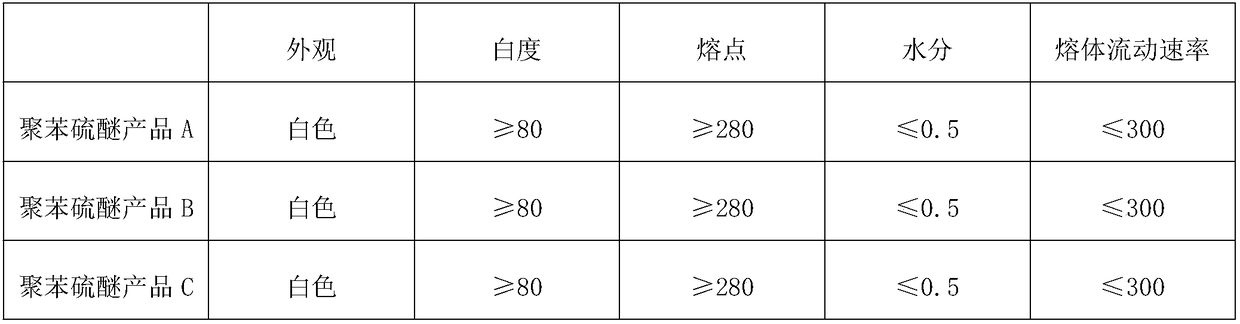

[0030] In a 25L pre-reaction kettle, add sodium sulfide trihydrate, NMP (N-methylpyrrolidone), sodium hydroxide and sodium acetate into the pre-reaction kettle at a molar ratio of 1:5:0.02:0.02, and then add A certain amount of deionized water, control the addition of deionized water to ensure that the mol ratio of sodium sulfide and water (comprising crystal water and free water) in the system is 1:10, open the pre-reactor to stir before heating up, and open the nitrogen gas to the pre-reactor simultaneously. The gas phase space of the reaction kettle is replaced, the replacement time is 10 minutes, and then the temperature of the system is raised to 150°C by electric heating, and the temperature is maintained until the complete reaction forms a stable ternary complex. It takes 30 minutes to obtain the aqueous sodium sulfide reaction Precursors (i.e. intermediates).

[0031] Continue to use heat conduction oil to raise the temperature of the pre-reactor to 190°C, and use a vacu...

Embodiment 2

[0037] In a 25L pre-reaction kettle, add sodium sulfide nonahydrate and formamide into the pre-reaction kettle at a molar ratio of 1:10, then add a certain amount of deionized water, and control the amount of deionized water added to ensure that the system The molar ratio of sodium sulfide to water (including crystal water and free water) is 1:20. Before the temperature rises, the pre-reactor is turned on for stirring, and at the same time, nitrogen is turned on to replace the gas phase space of the pre-reactor. The replacement time is 10 minutes, and then electric heating is used. The method is to raise the temperature of the system to 180°C, and maintain this temperature until the complete reaction forms a stable ternary complex. It takes 40 minutes to obtain a water-containing sodium sulfide reaction precursor (ie, an intermediate).

[0038] Continue to use heat transfer oil to raise the temperature of the pre-reactor to 208°C, and use a vacuum pump to control the vacuum of ...

Embodiment 3

[0041] In a 25L pre-reaction kettle, add sodium sulfide pentahydrate, 2-pyrrolidone, and sodium hydroxide into the pre-reaction kettle in a molar ratio of 1:8:0.02, and then add a certain amount of ion-free water to control the ion-free The amount of water added ensures that the molar ratio of sodium sulfide to water (including crystal water and free water) in the system is 1:15. Before the temperature rises, the pre-reactor is opened to stir, and nitrogen is opened to replace the gas phase space of the pre-reactor. After 10 minutes, the temperature of the system was raised to 160°C by means of electric heating, and the temperature was maintained until the complete reaction formed a stable ternary complex. It took 30 minutes to obtain the aqueous sodium sulfide reaction precursor (ie intermediate).

[0042] Continue to use heat transfer oil to raise the temperature of the pre-reactor to 200°C, and use a vacuum pump to control the vacuum of the system to 0.095MPa, and then remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com